In the context of modern electronic devices that increasingly pursue miniaturization and high precision, wiring harnesses, as important components connecting internal components of devices, have a direct impact on the stability and service life of the entire machine with their performance and selection. Although ultra-fine coaxial harnesses and ordinary harnesses look similar on the surface, there are significant differences in structure, performance, and application scenarios. If the selection is incorrect, it may not only lead to rework but also, in severe cases, cause equipment failure, signal interference, and even data loss. Below, we will analyze the differences between the two in detail, so that you can choose harnesses without confusion.

What is a micro coaxial cable assembly?

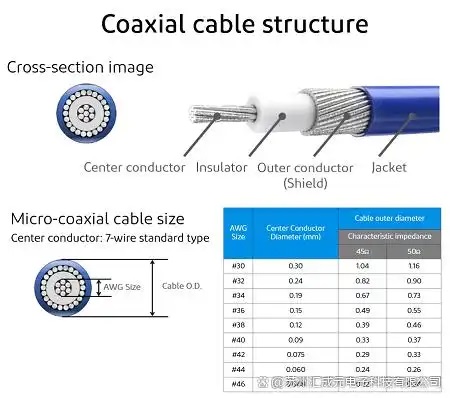

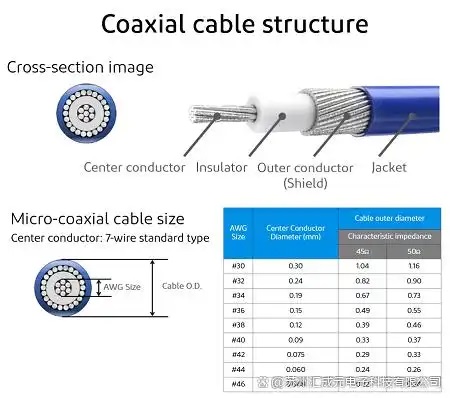

The ultra-fine coaxial cable assembly (Micro Coaxial Cable Assembly) consists of multiple micro coaxial cables, with diameters generally ranging from 0.2mm to 1.2mm. Its internal structure includes:

Conductor

Insulation layer

• Shielding layer

Outer wrapped

The advantage of coaxial structures lies in their strong anti-interference capability, stable signal transmission, and are particularly suitable for high-frequency, high-speed, small space, and high-density wiring environments.

What is a standard harness?

Common wire harnesses are composed of multiple single-core or multi-core wires, which are formed into fixed material assemblies through binding, covering, or connectors. They are mainly used for internal connections in household appliances, vehicles, and industrial equipment, and are suitable for low-frequency signals or power transmission.

What problems can arise from selecting the wrong harness?

Signal transmission distortion

In high-frequency or high-speed data transmission scenarios, using ordinary cable harnesses can easily cause signal attenuation and distortion, affecting equipment performance.

Serious interference

The ordinary wire harness has weak anti-interference capability, and it is prone to electromagnetic interference in high-density and high-frequency environments, leading to abnormal data.

Wireway space is limited

The wire diameter of ordinary harnesses is thicker, with a larger bending radius, which is not suitable for the delicate wiring requirements of miniature devices.

• Difficulty in post-maintenance

Choosing the wrong harness can lead to loose connections and cracked solder joints, increasing maintenance and repair costs.

Four, examples of application scenarios

Medical endoscope: The ultra-fine coaxial cable bundle ensures high-definition image transmission at high speed, with the surgical view being clear and interference-free in real time.

DJI Camera Module: Stable signal and anti-interference, ensuring uninterrupted image transmission.

High-end camera: supports 4K/8K high-definition video transmission, ensuring smooth and clear images.

The ultra-fine coaxial cable bundle and the ordinary cable bundle have obvious differences in performance, structure, and application scenarios. For high-frequency and high-speed signal transmission and miniaturized device wiring, it is necessary to use ultra-fine coaxial cable bundles. Otherwise, it not only affects the performance of the device but may also cause serious usage issues.

We have been focusing on the design and customization of high-speed signal cable harnesses and ultra-fine coaxial cable harnesses for a long time, committed to providing stable and reliable high-speed interconnection solutions. If you have any related needs or would like to learn more, please contact: Manager Zhang.

18913228573 (WeChat same number).