Categorization:Harness Component

In AI servers, camera modules, machine vision, and high-performance embedded devices, high-speed wiring harnesses are both the performance core and a significant component of procurement costs. Faced with the dual pressures of cost and performance, how to reduce costs while ensuring signal quality has become a topic of common concern for R&D and supply chains. This article will combine industry practices to discuss the key factors affecting costs and analyze the potential cost-saving advantages of micro coax (extremely thin coaxial cable).

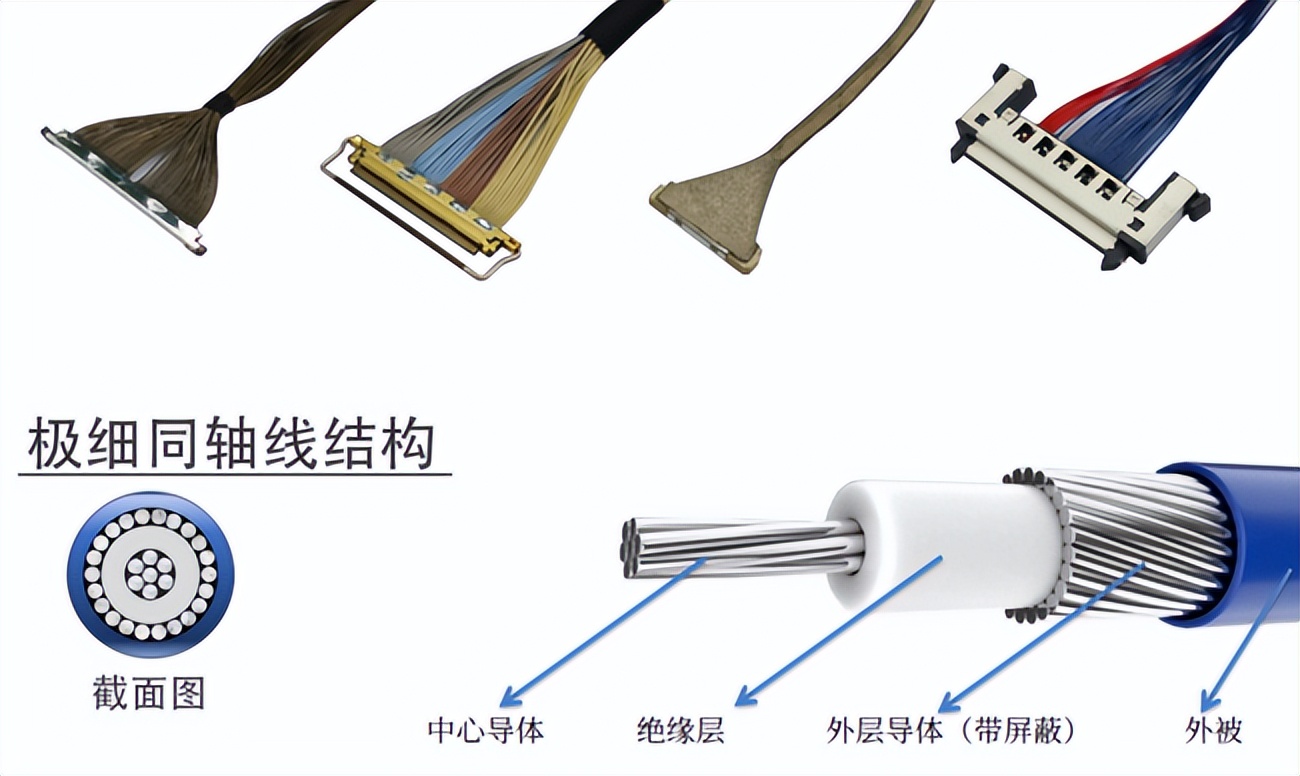

What is a micro coaxial cable (极细同轴线)?

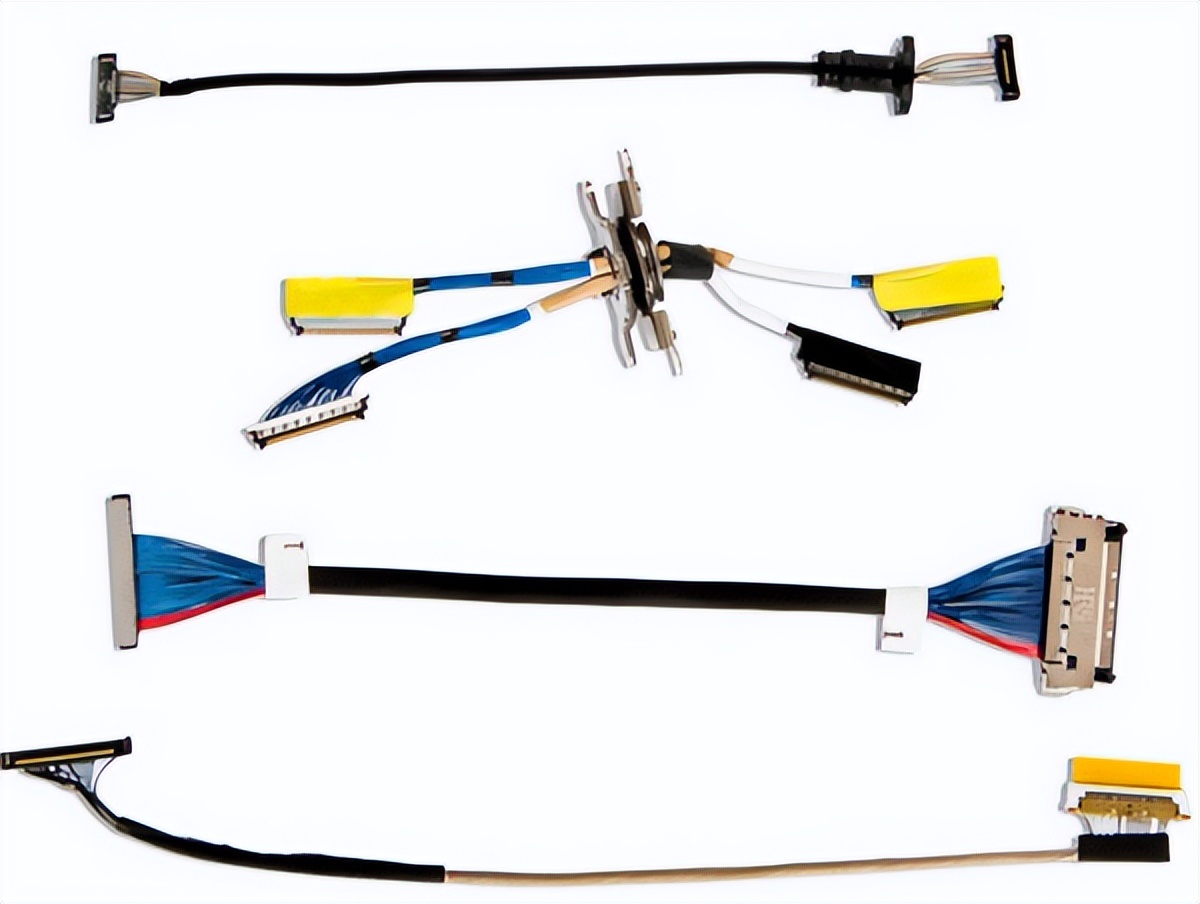

A super-fine coaxial cable is a type of coaxial cable with a very small outer diameter, featuring good shielding performance and fixed impedance characteristics. It is widely used in short-distance links for high-speed signals such as MIPI, USB3. Its main advantages include high flexibility, high wiring density, and good anti-interference ability, making it particularly suitable for camera modules, high-resolution display links, and high-speed devices in compact spaces.

What are the main components contributing to the cost of high-speed harnesses?

The cost of high-speed harnesses is composed of multiple factors, including:

The purity of the conductor, the medium material, and the electromagnetic shielding structure will all directly affect the price.

2.2 Connector and termination: For extremely thin coaxial cables, special connector interfaces are required, and the precision of the termination process is higher.

2.3 Assembly and Labor: High standards are required for welding, stripping, and testing due to fine wire diameters, with both manual and automated processes requiring substantial investment.

2.4 Test and Repair: The high-speed link must undergo comprehensive verification, and any repair may further increase costs.

Micro coax potential opportunities for cost reduction

Although ultra-fine coaxial cables may seem costly, they can actually lead to cost savings in the following scenarios:

3.1 High-density and space-limited design: Compared to differential pairs, extremely thin coaxial cables can complete wiring with a smaller volume, reducing structural complexity and assembly costs.

3.2 PCB Cost Optimization: Using coaxial cables instead of complex high-speed differential routing can reduce the number of PCB layers or shorten the routing, thereby lowering the material and design costs.

3.3 Scaling and Standardization: Converting small batch customization into general specifications, combined with centralized procurement strategies, can significantly reduce unit costs.

Four, limitations and inapplicable scenarios of extremely fine coaxial lines

Extremely thin coaxial cables have advantages, but they are not suitable as the first choice in all schemes:

4.1 For high-speed buses with strict differential requirements, differential pair or twinax solutions are more optimal.

4.2 For links with ultra-long distance and ultra-low loss requirements, fiber optics offer a higher cost-performance ratio.

4.3 If the cost of the matching connector is too high, there will not be real cost reduction in the short term.

The core strategies for reducing costs in high-speed harnesses

To truly reduce the cost of high-speed harnesses, it is necessary to coordinate the entire system design and supply chain.

5.1 Reasonably optimize structure: Reduce unnecessary length and complexity.

5.2 Specification Unification: Reduce redundant development and improve production efficiency.

5.3 Improve automation level: reduce manual reliance and minimize the risk of repair.

5.4 Bulk and Long-term Procurement: Lock in supply prices and ensure delivery stability.

5.5 Preliminary comparison of multiple schemes: Evaluate the total cost of ownership for various combinations of schemes, such as coaxial, differential, flexible PCB, and fiber optics, at the initial design stage.

The cost reduction of high-speed harnesses is not simply a "replacement with cheaper materials," but rather achieved through design optimization, standardization, automation, and supply chain collaboration. Micro coax cable indeed has a clear cost advantage in applications with high density, short distance, and high shielding requirements, but it is not the best choice in specific high-speed differential or long-distance links. Enterprises should make a comprehensive assessment in the early stage of design, supporting the final scheme choice with data.

I am[Suzhou Huichengyuan Electronic Technology], Focus on the development and customization of high-speed signal cables and ultra-fine coaxial cables, committed to creating stable and efficient high-speed interconnection solutions for customers. If you are planning a project or need technical evaluation, welcome to contactManager Zhang 18913228573 (WeChat same number)We will provide you with professional support with sincerity.