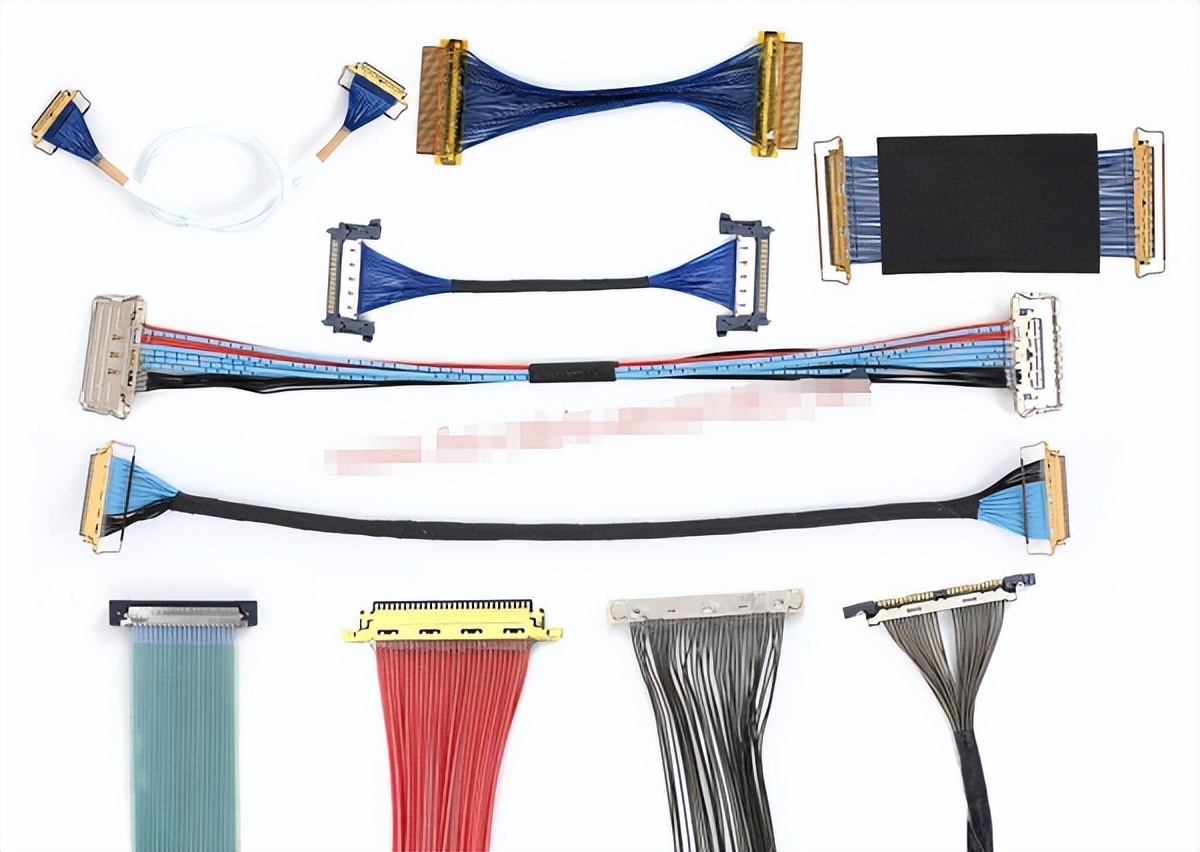

Categorization:Harness Component

In today's high-density and high-frequency parallel electronic device design, ultra-fine coaxial cable (micro coaxial cable) is widely used in intelligent terminals, communication modules, and precision control systems due to its lightweight, flexible, and excellent anti-electromagnetic interference performance. With the complexification of the operating environment of the equipment, especially the increasing prevalence of high-temperature working conditions, the temperature resistance of micro coax has become a focus of the industry. This article will comprehensively interpret its performance advantages in high-temperature environments from three aspects: material selection, structural design, and application performance.

Material Selection: Double Protection with High-Temperature Outer Sheath and Metal Conductor

High-temperature polymer sheath

Under extreme conditions, the sheath material of micro coax cables is particularly critical. Common high-temperature polymers such as PFA and FEP can not only withstand a temperature range of about -50°C to 200°C but also have excellent chemical resistance and electrical insulation properties. This makes them outstanding in fields such as industrial automation, aerospace electronics, and medical equipment, and they are not easily aged or cracked even after long-term operation.

Silver-plated conductor structure

Under high-temperature conditions, in order to further improve electrical stability, conductors and shielding layers usually use silver-plated copper wire. This structure can still maintain excellent conductivity at high temperatures, effectively reduce signal attenuation, and at the same time, extend the service life of the entire wire harness.

Section Design: Miniature size brings higher heat dissipation efficiency

Extremely fine wire diameter, rapid heat dissipation

A significant advantage of Micro coax cable is its extremely small cross-section and large heat dissipation area, which can quickly release heat in high-temperature environments, preventing performance degradation due to heat accumulation. Compared with traditional coaxial cables, it has greater stability in compact spaces.

Multi-core combination and reasonable layout

In multi-channel signal applications, engineers usually combine multiple micro coaxial cables, through reasonable arrangement and spacing design, to enhance overall heat dissipation capability, and avoid heat concentration in the internal core area, thereby ensuring the reliability of the system under long-term high-temperature operation.

Three, practical application: high-temperature test to verify its reliability

In industrial machinery, automotive engine compartments, and aerospace electronics, micro coax cables often need to withstand continuous high temperatures exceeding 150°C. Experimental data shows that products with PFA or FEP sheathes maintain stable signal quality after continuous operation at 165°C, with no melting, cracking, or obvious aging of the cable, demonstrating extremely high reliability and heat resistance.

The temperature resistance of micro coaxial cable comes from the dual support of high-temperature polymer materials and precise structural design. The sheath materials such as PFA and FEP allow it to work stably within a wide temperature range of -50°C to 200°C, while its slender dimensions and optimized heat dissipation structure further enhance its stability under high temperatures. In demanding fields such as industrial automation, vehicle electronics, aerospace, micro coax has become a reliable high-density signal transmission solution.

I amSuzhou Huichengyuan ElectronicsLong-term focused on the design and customization of high-speed signal cables and ultra-thin coaxial cables, committed to providing customers with high-quality, high-reliability high-speed interconnection solutions. If you have related needs or want to learn more, please contact:Manager Zhang 18913228573 (WeChat same number)。