Categorization:Harness Component

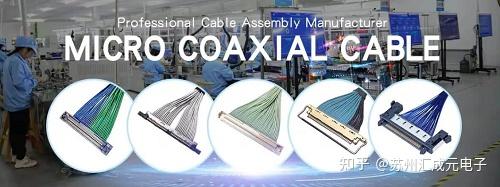

Today, with the continuous evolution of high-speed transmission and miniaturized design, "extremely thin coaxial cable (Micro Coaxial Cable)" has become a frequently mentioned keyword in the design of AI vision modules, notebook cameras, in-car imaging systems, and drones.

But in the actual selection process, many engineers encounter a common problem: once the cable is determined, how should the connector be chosen?

To truly understand the performance of the entire system, it is necessary to first clarify—what is a "micro coaxial connector"? And what is the collaborative relationship between it and a micro coaxial cable?

What is a ultra-fine coaxial connector?

Extremely thin coaxial connectors are a miniature interface specially designed for Micro Coax cable assemblies.

Its internal structure is composed of multiple layers of components such as the central needle, insulator, shielding layer, and shell, designed to achieve reliable signal connection and impedance matching in a minimal space.

Compared with traditional RF connectors such as SMA, MCX, the ultra-thin coaxial connectors have a smaller size, with a pitch typically only 0.25mm to 0.5mm, belonging to micro-pitch, high-density structures, which are very suitable for the transmission of high-speed signals within the device.

Common series include:

I-PEX 20373 / 20454

Hirose DF36 / DF81

JAE FI-R / FI-X

These products are widely used in laptop cameras, AI vision modules, industrial cameras, and automotive display modules.

They are not only small in size and light in weight, but also have excellent shielding performance, which can support high-speed data transmission of 5Gbps to more than 10Gbps.

The collaborative relationship between ultra-fine coaxial cables and connectors

The extremely thin coaxial cable can be likened to "the blood vessels of the signal," while the connector is "an accurate joint."

Cables are responsible for transmitting high-speed signals, connectors are responsible for stable connection, mechanical fixation, and signal conversion. Only when both are closely matched can the complete signal quality be maintained at the connection point.

The Micro Coax line structure is extremely precise:

Conductors generally use silver-plated copper wire (AWG40~42).

Outer diameter is only about 0.25~0.5mm.

Equipped with multi-layer insulation and shielding design.

Connectors must use high-precision stamping and gold-plated terminals, and employ 360° shielding welding to prevent electromagnetic interference and signal crosstalk.

If the connector design or welding process is poor, even if the cable performance is high, it may still result in impedance突变, signal reflection, or eye diagram collapse and other issues.

Therefore, many manufacturers provide solutions not as separate cables or connectors, but as complete harness + connector systems, which have undergone complete MIPI or USB4 conformance testing to ensure signal integrity and stability.

Why can't AI and image systems do without it?

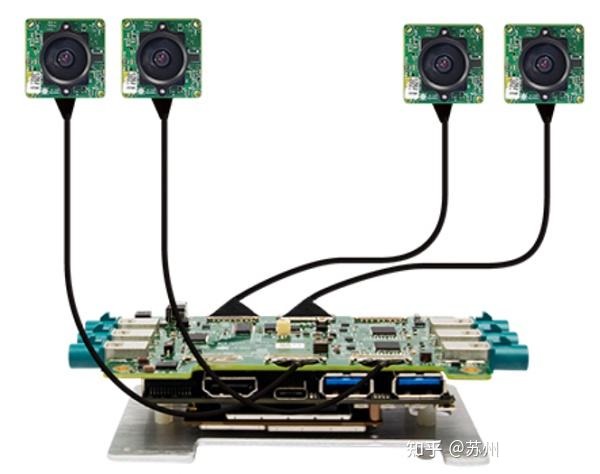

Image modules for fields such as AI vision, autonomous driving, and industrial inspection have extremely high requirements for bandwidth, flexibility, and space occupation.

Traditional FPC ribbon cables have limitations in terms of anti-interference, bend life, and signal consistency, while Micro Coax cable assemblies have obvious advantages:

Strong anti-interference capability: 360° full-shielding structure, which can effectively isolate external electromagnetic noise.

High signal consistency: the impedance of each line is controlled within 90Ω±10%, ensuring multi-channel signal synchronization.

Good flexibility and bendability: suitable for wiring in narrow spaces, especially for foldable screens or camera modules.

Therefore, the high-speed transmission between AI motherboards and camera module groups almost all adopt the Micro Coax solution. Whether it is a four-channel or eight-channel design, it can achieve both high speed and stability.

Four, the "Invisible Barrier" in Manufacturing and Assembly

Although it appears simple in appearance, the processing requirements for ultra-fine coaxial beam are extremely high.

For example, the center conductor of AWG42 is finer than a hair, and stripping, welding, and crimping all depend on high-precision equipment.

Connector焊点间距usually不足0.3mm,任何细微的虚焊、锡珠或偏位,都可能导致短路或信号异常。

Therefore, manufacturers that produce high-quality Micro Coax cable usually equip themselves with:

Automatic coaxial cable manufacturing equipment

Vision positioning welding system

TDR high-speed signal tester.

These manufacturers not only have precision processing capabilities, but must also have a complete high-speed signal verification system to ensure that each harness has stable performance before leaving the factory.

The ultra-thin coaxial cable and its dedicated connector are known as the "gold combination" in the field of high-speed interconnection.

The former provides a high-speed signal path, and the latter ensures reliable mechanical and electrical connections.

The degree of fit between them directly determines the stability of AI devices and the data transmission speed.

As devices continue to become lightweight and interface speeds increase, the Micro Coax solution is gradually becoming the mainstream interconnection method for AI and industrial vision systems.

I am[Suzhou Huichengyuan Electronic], long-term focused on the design and customization of high-speed cable harnesses and ultra-fine coaxial cables, committed to providing customers with stable and reliable high-speed interconnect solutions.

Welcome to contact us if you have related needs or wish to learn more.Manager Zhang 18913228573 (WeChat same number)。