Categorization:Harness Component

In fields such as consumer electronics, communication equipment, medical imaging systems, and industrial automation, both extremely thin coaxial cables (micro coaxial cable) and FPC cables (flexible printed circuit cables) are common signal interconnection solutions. While they may appear similar in appearance, there are significant differences in their electrical performance, mechanical properties, and application directions. The following is a systematic analysis from four aspects.

Signal integrity and anti-interference capability

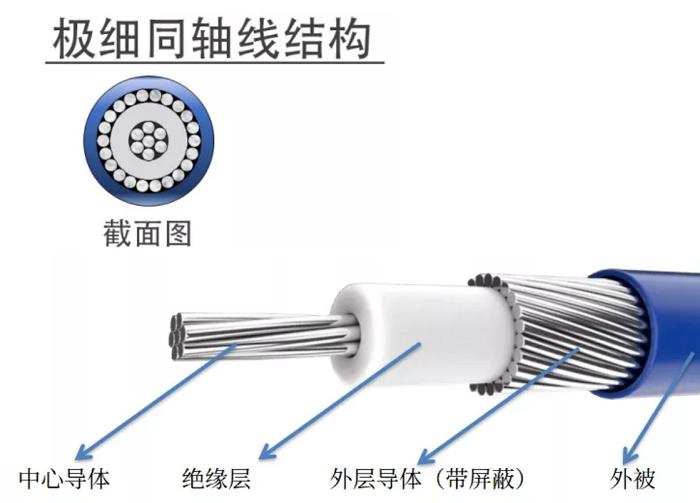

The ultra-fine coaxial cable bundle uses a typical coaxial shielding structure, with an outer conductive shielding layer, which can significantly reduce the impact of electromagnetic interference (EMI).

In high-speed and high-frequency signal transmission scenarios, its signal integrity and stability are particularly outstanding.

Compared to FPC cables, although they are thin, light, and flexible, most products lack an independent shielding layer, have limited anti-interference performance, and are more suitable for applications with lower signal rates and lighter interference environments.

Flexibility and wiring freedom

The FPC cable, due to its planar design, can flexibly bend, fold, and lay out in extremely narrow spaces, and is widely used for internal connections in display screens, camera modules, and small-sized devices.

And the extremely fine coaxial beam, although structurally complex, also has good flexibility and bending resistance.

In the parts that require frequent movement or bending, such as notebook hinges, folding smartphones, and drone gimbals, it can achieve reliable wiring while maintaining signal stability.

Part 3: Transmission Rate and Application Scenarios

Extremely thin coaxial cable束 supports GHz-level high-speed transmission with advantages of low loss and low error rate, which is very suitable for scenarios such as high-speed image transmission, millimeter wave communication, AR/VR systems, and high-end medical imaging equipment.

FPC cables are commonly used for medium and low-speed transmission, such as LCD display ribbon cables and battery module to motherboard connections, which can meet regular signal requirements while also considering structural thinness and cost control.

Four, Cost and Manufacturing Efficiency

FPC cable technology is mature, with high manufacturing efficiency and low cost, suitable for mass production of consumer electronic products.

Compared to other types of coaxial cable bundles, the manufacturing process of extremely fine coaxial cable bundles is more precise, requiring higher assembly and processing accuracy, thus resulting in higher costs.

But in fields requiring high performance and high reliability, its value far exceeds its price itself.

The ultra-fine coaxial cable束and FPC cableare not mutually substitutable; they are complementary solutions for different performance requirements.

The former has more advantages in high-speed transmission and anti-interference, suitable for high-end and critical applications; the latter is known for its thinness, flexibility, and low cost, suitable for mass production and cost-sensitive designs.

The reasonable selection of both is essential to achieve an ideal balance between performance and cost.

I am[Suzhou Huichengyuan Electronic]Focused on the research and development, as well as customization, of high-speed signal cables and ultra-thin coaxial cables, providing customers with high stability and consistency interconnection solutions.

If you have any related needs or technical inquiries, please feel free to contact:Manager Zhang 18913228573 (WeChat same number)We will provide you with professional support.