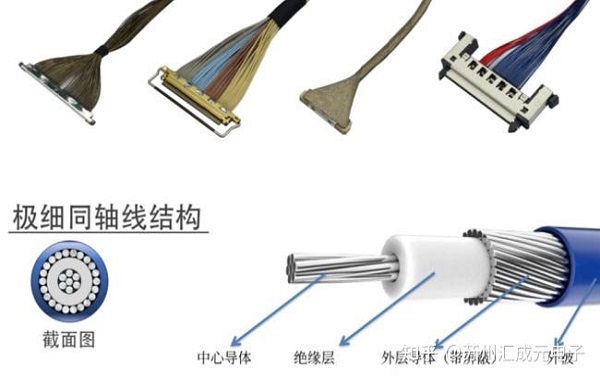

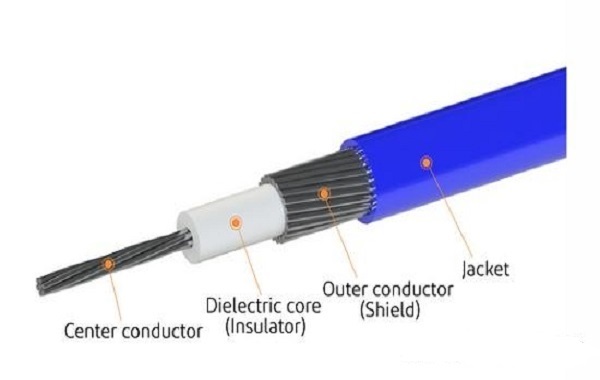

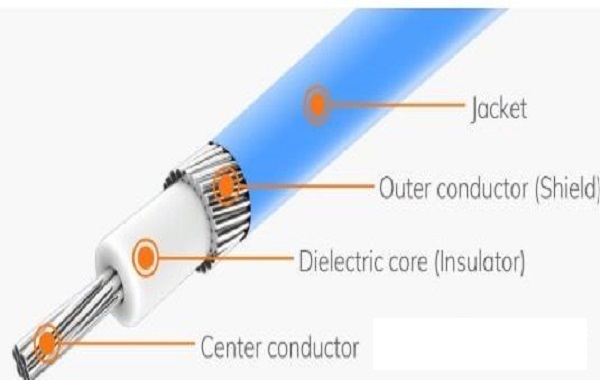

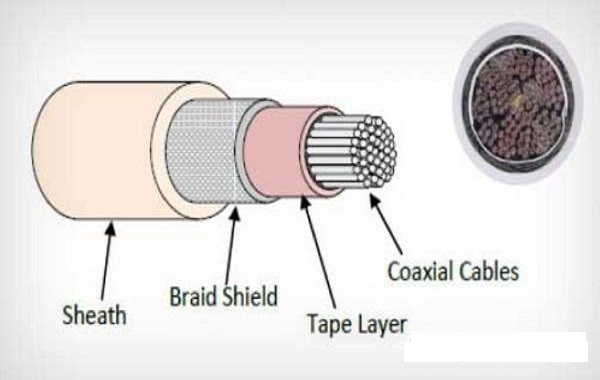

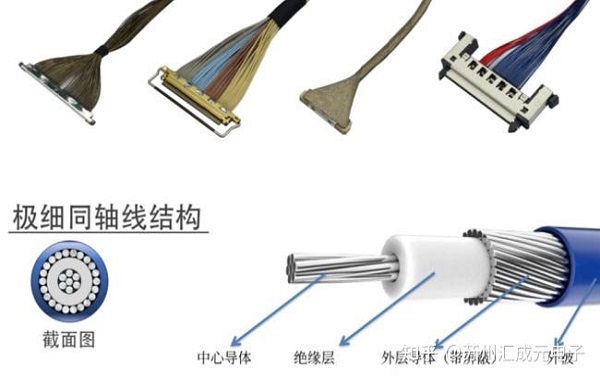

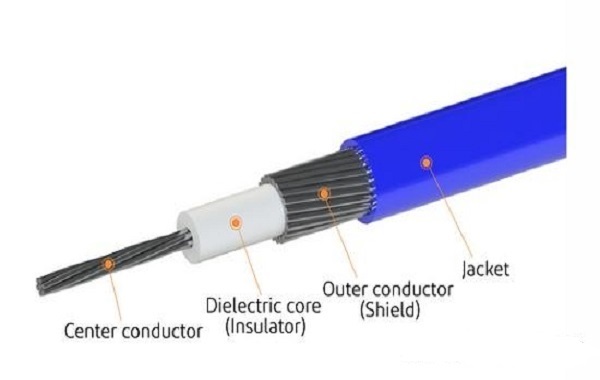

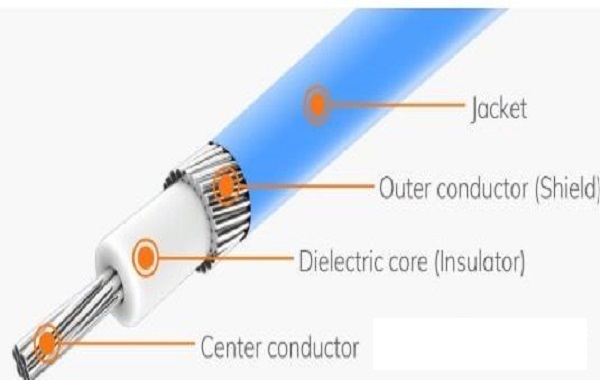

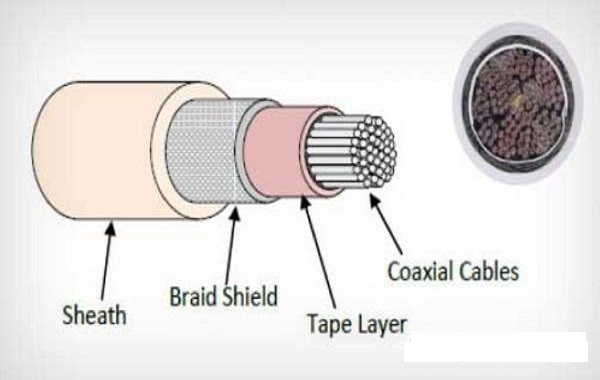

In high-precision products such as smartphones, laptops, medical probes, and industrial testing equipment, extremely thin coaxial cables (Micro Coaxial Cable) are almost irreplaceable high-speed signal transmission solutions. They can achieve stable high-frequency transmission within limited space, and at the same time, they have the characteristics of strong flexibility and long bending life. In such cable structures, dielectric materials – that is, the insulating layer wrapped around the inner conductor – play a crucial role. Dielectric materials not only affect signal loss, characteristic impedance, and frequency response, but also directly determine the durability of the cable. Therefore, understanding the characteristics and application scenarios of different dielectric materials is crucial for designing high-performance ultra-thin coaxial cables.

One, solid polyethylene (Solid PE)

Solid polyethylene is the most traditional and common dielectric material for extremely fine coaxial cables. Its structure is simple, the cost is low, and the mechanical strength is high, showing stable performance in low-frequency signal transmission. However, due to its relatively high dielectric constant, the attenuation of high-frequency signals is significant, and its performance is limited in high-speed transmission scenarios. Solid polyethylene is suitable for cost-sensitive applications with low transmission frequencies and is an ideal choice for low-speed or entry-level scenarios.

Foam Polyethylene (Foam PE)

Foamed polyethylene reduces the dielectric constant by introducing air bubbles within the material, thereby reducing signal attenuation and improving transmission speed. It has good flexibility, suitable for frequent bending and high bandwidth transmission scenarios. However, the foamed structure is sensitive to humidity, and if there is no moisture-proof design, long-term use may affect performance. Therefore, foamed polyethylene is a cost-performance compromise choice for high-speed data transmission.

Three, polytetrafluoroethylene (PTFE) and perfluoroalkoxy resin (PFA)

PTFE is a representative material for high-end ultra-fine coaxial cables, with extremely low dielectric constant and small signal loss. It can maintain stable performance in high temperature, high humidity, and harsh environments, and is suitable for high-performance scenarios such as medical probes, aerospace, and 5G communication. However, it is difficult to process and has a high cost. PFA has similar performance to PTFE, and also has better processing and molding performance as well as chemical corrosion resistance. It is very reliable in scenarios with long-term stable use, such as industrial testing and medical imaging.

Four, material performance comparison and selection strategy

Different materials have their respective advantages: solid polyethylene has a low price and simple structure, but its high-frequency performance is limited; expanded polyethylene performs better in controlling signal loss, but attention must be paid to humidity protection; PTFE excels in high-frequency, high-temperature, and harsh environments and is the preferred choice for high-performance applications; PFA combines high performance, processing flexibility, and chemical resistance, making it very suitable for long-term use in industrial and medical fields. In the design of extremely fine coaxial cables, the choice of dielectric material directly determines the quality of signal transmission and the life of the system.

Dielectric materials act as the "heart" of ultra-fine coaxial cables, and choosing the right material is essential for achieving high-speed, stable signal transmission and extending the service life of the system. For applications that pursue high frequency, low loss, and long life, PTFE and PFA are ideal solutions; when seeking a balance between performance and cost, expanded polyethylene is a compromise choice; and in cost-sensitive and low-frequency applications, solid polyethylene is still capable of performing the task.

I am

[Suzhou Huichengyuan Electronic Technology], Long-term focused on the design and customization of high-speed cable harnesses and ultra-fine coaxial cable harnesses, committed to providing customers with stable and reliable high-speed interconnection solutions. For more information or customized services, please contact:

Manager Zhang 18913228573 (WeChat same number)。