Categorization:Harness Component

The key to determining the temperature resistance: insulating material

The stability of ultra-fine coaxial cables in high-temperature environments is most critically determined by the insulating and sheath materials. The temperature resistance levels of different materials directly determine the working upper limit of the cables.

PFA (perfluoroalkoxyane): Capable of withstanding high temperatures of about 260°C, commonly used in demanding aviation, medical sterilization, and industrial testing environments.FEP (fluorinated ethylene propylene): It has excellent dielectric properties and chemical resistance, and can usually withstand continuous high temperatures around 200℃.

ETFE (ethylene-tetrafluoroethylene copolymer): temperature resistance of about 150℃, but with higher mechanical strength, suitable for applications requiring high flexibility and wear resistance.

Compared with traditional PVC cables (with a temperature resistance of about 75℃), these fluoro plastics materials endow the ultra-fine coaxial cables with higher safety margin and long-term reliability, enabling them to maintain stable electrical performance under extreme conditions.

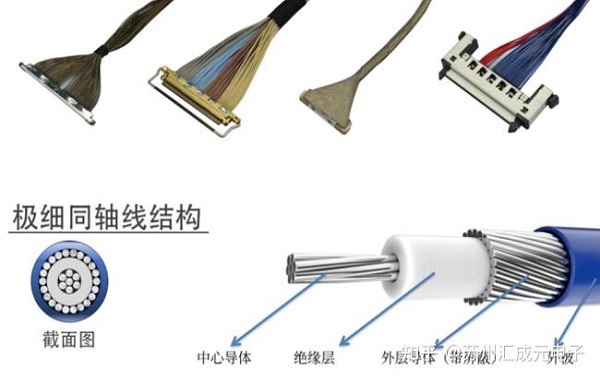

Optimization of structure for more stable performance

In addition to material selection, the internal structure of cables also affects their stability under high-temperature conditions. High-end ultra-fine coaxial cables usually adopt foam core or solid core structures to maintain consistent impedance and phase consistency during temperature fluctuations. This structural design can effectively reduce signal reflection or delay errors caused by temperature changes, which is particularly important for systems requiring high-frequency signal transmission. For example, in radar equipment, aerospace control modules, or high-speed testing instruments, ultra-fine coaxial cables can still ensure signal integrity and system reliability even under drastic temperature changes.

Typical application scenarios and performance

Different application environments have varying requirements for temperature resistance, and the following are several typical applications:

Medical equipment: Fine coaxial cables insulated with PFA or FEP can withstand high-temperature steam sterilization processes without performance degradation.Aerospace system: Inside the aircraft and satellite cabin, there is a dramatic change in temperature, with both high temperatures and radiation. The coaxial cable optimized in the structural design can maintain signal stability and electrical isolation.

High-end electronic instruments: In test equipment with high temperature control accuracy but limited space, extremely thin coaxial cables combine flexibility and heat resistance to ensure precise signal transmission.

Extreme high temperature environment (>260℃): If the working limit of PFA material is exceeded, a higher temperature-resistant material such as Kapton (polyimide) should be used to ensure long-term safe operation.

These actual cases fully prove that ultra-fine coaxial cables not only have excellent heat resistance but also maintain stable electrical and mechanical properties under various complex conditions.

I am[Suzhou Huichengyuan Electronic Technology]Long-term focus on the design and customization of high-speed signal cables and ultra-fine coaxial cables, committed to providing stable and reliable high-speed interconnect solutions. If you have any related needs or want to learn more, please contact:Manager Zhang 18913228573 (WeChat number the same)。