Categorization:Harness Component

Smaller volume, more possibilities

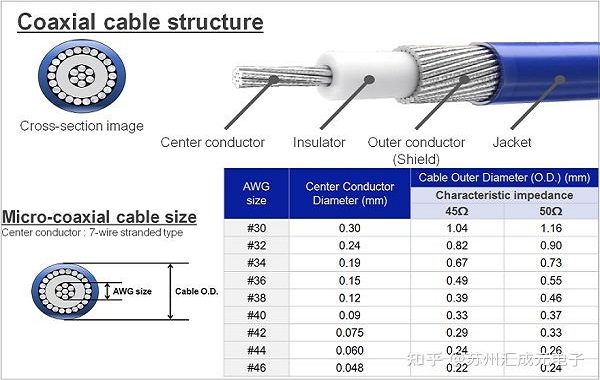

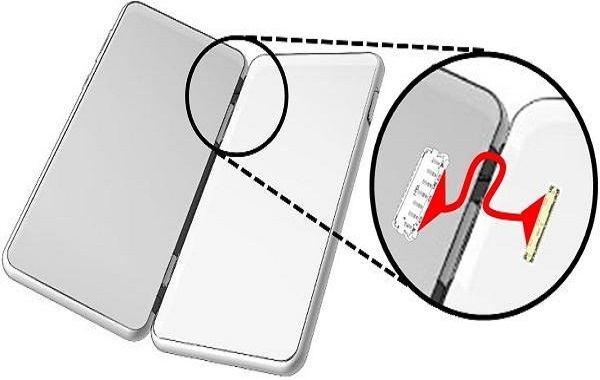

The diameter of extremely fine coaxial cables can reach 0.3mm and even smaller. On a circuit board as small as the size of a palm, if multiple high-speed signals need to be transmitted simultaneously, traditional FPC cables are prone to occupy space, while micro coax can arrange the cables in gaps that were previously difficult to utilize. Therefore, it has almost become a standard configuration for small electronic devices such as mobile phone camera modules, providing possibilities for high-density wiring.

Signal is stable, not afraid of interference.

In high-resolution cameras or industrial 4K/8K cameras, the occasional appearance of snowflakes or unstable signals is often due to wiring and electromagnetic interference issues. Extremely thin coaxial cables have built-in shielding, which can effectively reduce the impact of crosstalk and external noise. In comparison, FPC is more susceptible to interference during high-frequency signal transmission. Therefore, in high-speed data links and high-resolution video transmission scenarios, micro coax is a more reliable choice.

Flexible and bendable, suitable for dynamic applications

Flexible screens, robotic articulated arms, medical catheters, and other equipment are subjected to repeated bending and movement during use. In such an environment, ordinary ribbon cables tend to suffer fatigue damage easily, while ultra-fine coaxial cables, with their flexibility and fatigue resistance, are more suitable for dynamic applications, ensuring long-term stability of signal transmission.

Four, customizable, meeting special requirements

Different devices have different requirements for cables, some needing precise impedance control, while others require thicker shielding layers or special interfaces. Extremely thin coaxial cables support high customization, can be flexibly adjusted according to actual design, and meet the unique needs of various devices, giving them significant advantages in the design of miniaturized and high-performance equipment.

I am[Suzhou Huichengyuan Electronic Technology]Long-term focus on the design and customization of high-speed signal cable harnesses and ultra-thin coaxial cable harnesses, committed to providing stable and reliable high-speed interconnect solutions. If you have any related needs or would like to learn more, please feel free to contact:Manager Zhang 18913228573 (WeChat same number)。