Categorization:Harness Component

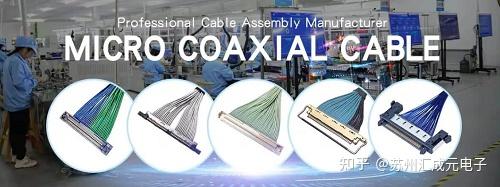

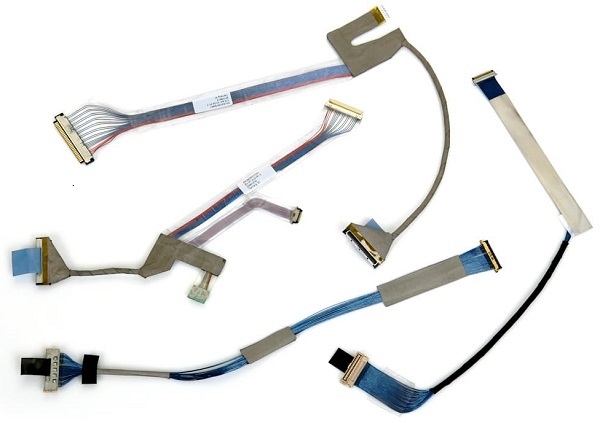

Today, with the continuous development of high-speed signal transmission, ultra-thin coaxial cables (Micro Coaxial Cable) have become an indispensable core component in precision electronic equipment. Whether it is the camera module of a smartphone, the LCD connection wire of a laptop, or the medical endoscope, drone camera module, all rely on its support. Compared with ordinary cables, the manufacturing and processing process of ultra-thin coaxial cables is much more complex, and each link puts forward extremely high requirements for accuracy and process level.

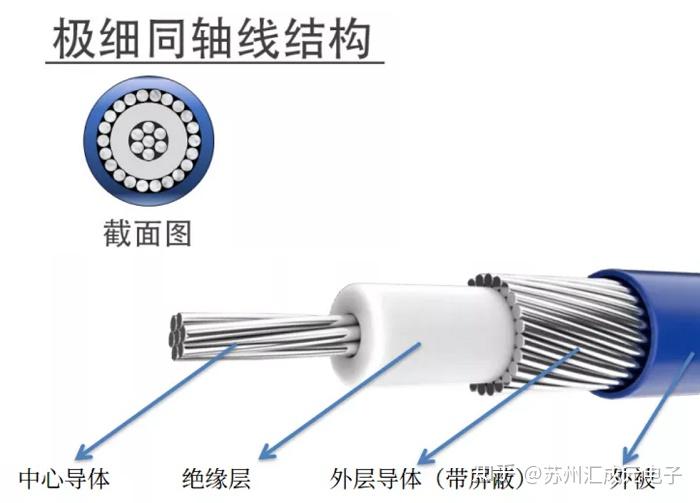

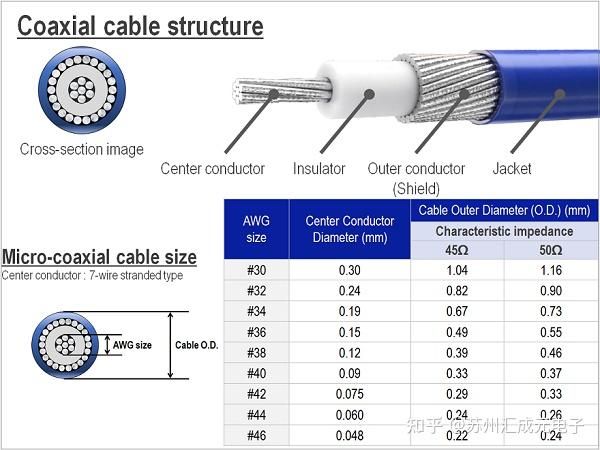

One, structurally precise, with strict requirements for dimension control

The outer diameter of extremely thin coaxial cables is usually only 0.3mm to 0.5mm, even finer. Such a tiny size means that each layer of structure——conductor, insulating layer, shielding layer, and sheath——must maintain extremely high precision. Any slight size deviation may cause impedance change, leading to signal distortion. Therefore, in the processing, strict control of peeling and cutting accuracy is not only required, but also specialized micro-processing equipment and high-precision fixtures are needed to ensure that each wire bundle meets the design standards.

Second, the design requirements for screening are stringent.

Due to the extremely small diameter of the ultra-fine coaxial cable, the shielding layer thickness is limited, but it must also have strong anti-interference performance. To this end, manufacturers usually adopt a high-density woven structure, or combine metal foil with woven layers to form multi-layer composite shielding. This design can effectively suppress electromagnetic interference (EMI) and ensure the integrity of the signal during high-speed transmission. However, any uneven weaving, poor overlap, or loose problems will directly affect the shielding effect and product consistency.

Welding and assembly technical challenges

The welding technology of ultra-fine coaxial cables can be said to be "a true skill seen in the smallest margin." The welding spot is extremely tiny, and overheating can easily burn the insulation layer, while welding deviation may cause cold soldering or short circuit. Therefore, it is usually necessary to complete the manual welding under a microscope, or adopt an automated spot welding device to achieve high precision control. At the same time, parameters such as the stripping length of the coaxial cable and the welding position of the terminals need to be strictly controlled, otherwise it will seriously affect the yield rate and product performance.

Four, promote technological improvement in application fields

The application range of ultra-fine coaxial cables is extremely wide, especially concentrated in high-end fields where both signal integrity and lightweighting are required: in the consumer electronics field for mobile phones, tablets, and notebook LCD modules; in the medical equipment field such as endoscopes and ultrasonic probes; in industrial detection with high-speed cameras and machine vision systems; and in lightweight signal transmission systems for drones and aerospace. Different application scenarios have extremely high requirements for flexibility, bendability, and reliability. Therefore, the level of technology directly determines the competitiveness of the product.

Extremely thin coaxial cables, although small, are a key component supporting high-speed transmission in electronic devices. They not only reflect the limit of microfabrication technology but also are an important embodiment of high-end interconnect technology. Only enterprises with high-precision and high-consistency processing capabilities can occupy a leading position in the high-speed interconnect industry in the future.

I am[Suzhou Huichengyuan Electronic]Long-term focus on the design and customization of high-speed cable harnesses and ultra-fine coaxial cable harnesses, committed to providing stable and reliable high-speed interconnection solutions. If you have related needs or want to learn more, please contact:Manager Zhang 18913228573 (WeChat same number)。