Categorization:Harness Component

Impedance Control and Differential Matching

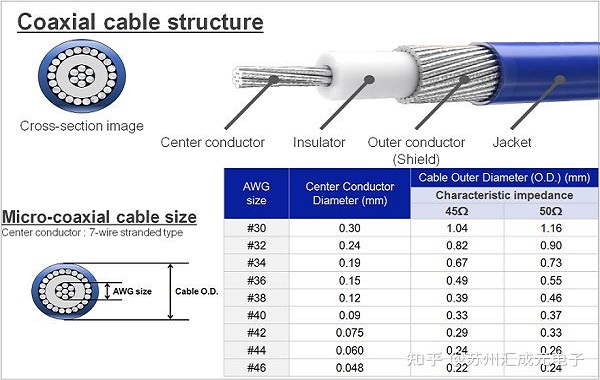

The core of differential signal design lies in impedance matching. Thin coaxial cables usually have a single-ended impedance of 50Ω, but for differential pairs, it is necessary to maintain an approximate differential impedance of 100Ω. In the design, appropriate specifications of coaxial cables should be selected according to interface standards (such as MIPI, USB, LVDS, etc.), and the lengths and structures of the two lines should be kept as consistent as possible to avoid signal reflections and intersymbol interference caused by impedance mismatch.

Maintain equal length and signal synchronization

Extremely thin coaxial cables are flexible and can be bent, but during wiring, if the lengths of the two wires differ greatly, it will cause signal skew (skew), resulting in different signal arrival times and affecting synchronization. It is recommended to plan the path before wiring, maintain equal length through reasonable wiring methods, especially in high-speed interfaces, where even a few millimeters of difference may affect signal quality.

Three, bend radius and shielding control

Due to the extremely small diameter of the ultra-fine coaxial cable, high requirements are placed on the bending radius. Sharp bending may damage the inner conductor and alter the electrical characteristics. It is usually recommended that the minimum bending radius be 5-10 times the wire diameter, while avoiding long-term mechanical stress. Although the built-in shielding layer can reduce external interference, when multiple coaxial cables are arranged in parallel, cross-talk may still occur. Therefore, it is necessary to maintain an appropriate spacing or optimize the shielding grounding method to ensure that there is no interference between the differential pairs.

Four, Connector Selection and Assembly Technology

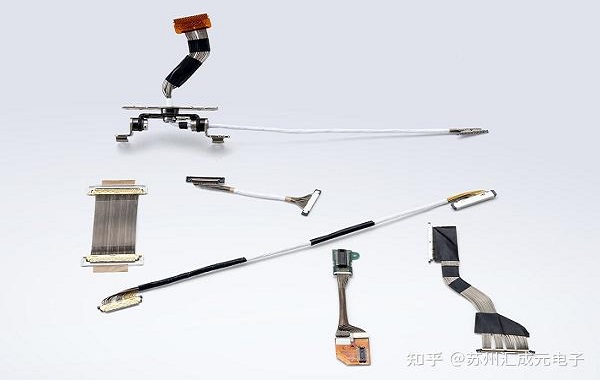

The extremely thin coaxial cables usually require the use of miniature connectors, such as the ultra-small pitch FPC/BTB connectors for MIPI interfaces. The assembly process must ensure reliable solder joints and complete grounding, while avoiding excessive stretching or twisting. Even if the cable performance is good, improper assembly can affect long-term stability and signal transmission quality.

I amSuzhou Huichengyuan Electronic TechnologyLong-term focus on the design and customization of high-speed signal cable harnesses and ultra-fine coaxial cable harnesses, committed to providing stable and reliable high-speed interconnection solutions. If you have any related needs or want to learn more, please contact:Manager Zhang 18913228573 (same number as WeChat)。