In minimally invasive surgical instruments, the cable, although small in size, often undertakes critical functions such as signal transmission, energy, and feedback. Due to the extremely compact space inside the instrument, it is necessary to ensure both signal quality and instrument reliability simultaneously, making cable design often a difficult point in the system engineering. Especially in key aspects such as image transmission, radio frequency output, and sensing feedback, once the cable is unstable, it may affect the overall performance of the equipment. This article, combining with the commonly concerned issues in the industry, discusses the design points and overall思路 of ultra-fine cables from two directions: space restriction and anti-interference.

Design Challenges under Space Constraints

Diameter restriction and flexibility requirement

The outer diameter of minimally invasive surgical instruments is usually only a few millimeters, while internally, they need to accommodate multiple wires, optical fibers, channels, and even structural components. Therefore, the cable束 must be as miniaturized as possible, while also having sufficient flexibility to maintain stability in the bent lumen, instrument joints, or rotating positions, and not to be damaged due to bending fatigue.

Multi-functional integrated requirements

A wiring harness may simultaneously bear signal transmission, power supply, and sensing feedback functions, and even need to run in parallel with optical fibers and cooling channels. How to reasonably layout within a limited cross-sectional structure is a key issue that must be considered during design.

Long-term reliability

Medical devices must withstand repeated operation, as well as high-temperature steam sterilization, chemical cleaners, and humid environments. The insulation layer of the wire harness, the conductor structure, and the sheath material must all have long-term stability to ensure that the mechanical and electrical properties do not明显 degrade with the number of uses.

Interference issue brings challenges

Electromagnetic Interference (EMI)

There are interference sources such as electrosurgical devices, ultrasonic equipment, and power systems in operating rooms. Without good shielding design, cables are easily affected, leading to signal fluctuations, increased noise, or image distortion.

Crosstalk and Reflection Issues

Cables in parallel are prone to crosstalk, and if the terminal impedance is not designed reasonably, reflections will occur, causing high-frequency signal attenuation and affecting transmission quality.

3. Integrity and grounding design

The shielding layer, if it has broken points, poor splicing, or discontinuous grounding, will significantly reduce the anti-interference ability, which is a hidden danger often neglected in actual engineering.

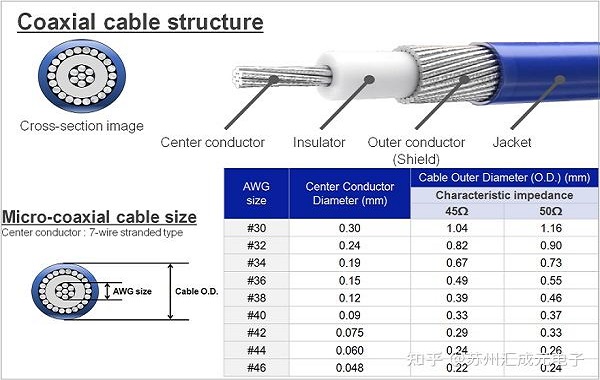

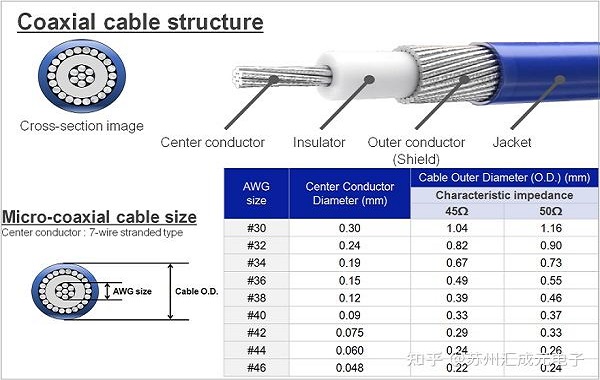

Micro coaxial cable (极细同轴线) technical advantages

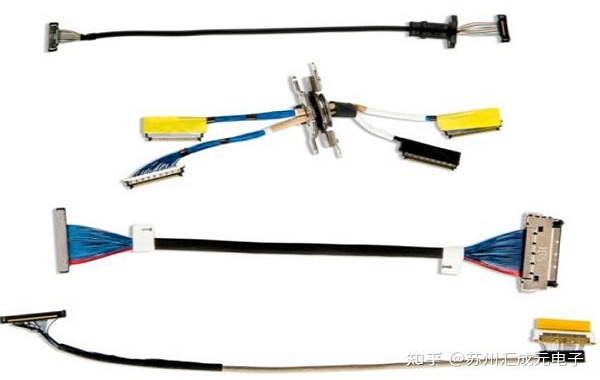

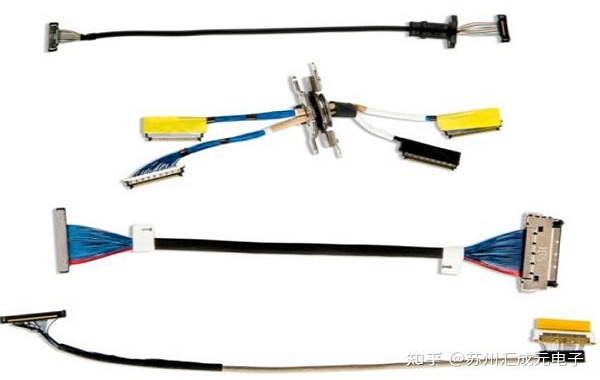

Micro coaxial cable is renowned for its extremely small outer diameter and coaxial shielding structure, and is one of the commonly used high-speed wires in minimally invasive instruments, suitable for ultra-fine specifications such as AWG32-50. Its core advantages include:

Natively equipped with shielding performance

The coaxial structure has an inherent shielding layer, which can effectively reduce EMI interference and crosstalk between adjacent signals.

Better signal integrity

The coaxial impedance consistency is excellent, which can reduce reflections and losses in high-frequency transmission, ensuring stable and clear imaging and data.

Super small outer diameter design

Extremely thin specifications can be achieved less than 0.3 mm, providing wiring possibilities for minimally invasive instruments in tight spaces.

High flexibility and bending resistance

Special conductor and insulation material design ensure reliability even when subjected to repeated bending, rotation, or movement within a cavity.

Outstanding mixed integration capability

Can be encapsulated together with optical fibers, power lines, cooling pipes, etc., as a mixed cable assembly, which helps to further reduce the size of the equipment and improve wiring efficiency.

Four, key points of micro-invasive instrument cable design

Reasonable selection of types and material selection

Select the appropriate coaxial specification based on signal type, frequency, and power requirements, and consider the impact of sterilization methods on the insulating and sheath materials.

Ensure continuity of shielding

The shielding between cables and connectors must be continuous to avoid the formation of shielding breaks at the interface, which reduces the ability to resist interference.

3. Terminal impedance matching

High-speed signal transmission requires consistent impedance to reduce reflections and losses, improving the stability of image and data acquisition.

4. Mixed harness integration capability

Integrating ultra-thin coaxial cables with fiber optics, power lines, or fluid pipelines can significantly improve space utilization and the reliability of the entire system's wiring.

5. Comprehensive verification test

Including items such as bend life, sterilization tolerance, signal integrity, and EMI immunity all need to be rigorously tested during the development stage.

The wire harness design in minimally invasive instruments is always seeking a balance between "space minimization" and "signal stability." To some extent, micro coaxial cable provides engineers with an efficient solution, not only meeting the wiring needs under extreme space conditions but also having excellent anti-interference capabilities. Through reasonable material selection, shielding strategies, terminal processes, and mixed packaging methods, it can greatly enhance the overall reliability and clinical use effect of the instrument.

I am[Suzhou Huichengyuan Electronic Technology]Long-term focus on the design and customization of high-speed cable harnesses and ultra-fine coaxial cable harnesses, committed to providing stable and reliable high-speed interconnection solutions. For inquiries or cooperation, please contact:Manager Zhang 18913228573 (WeChat same number)。