Categorization:Harness Component

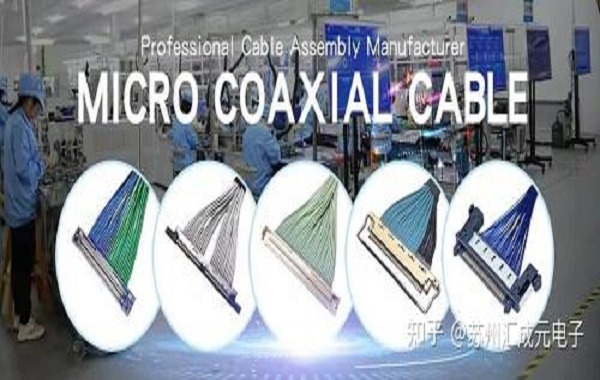

Micro coaxial cable is a coaxial cable with an extremely small outer diameter and stable structure, consisting of a conductor, insulation layer, shielding layer, and outer sheath. If you have ever come into contact with a mobile phone or camera module, you should not be unfamiliar with it. The reason it is commonly used is very straightforward:

High-speed signal transmission with low distortion rateExcellent flexibility, can be bent multiple times in a small space.

Strong shielding capability, stable anti-interference performance.Because of its three major characteristics of small size, high bandwidth, and strong anti-interference, it is almost an inevitable choice for AR/VR devices.

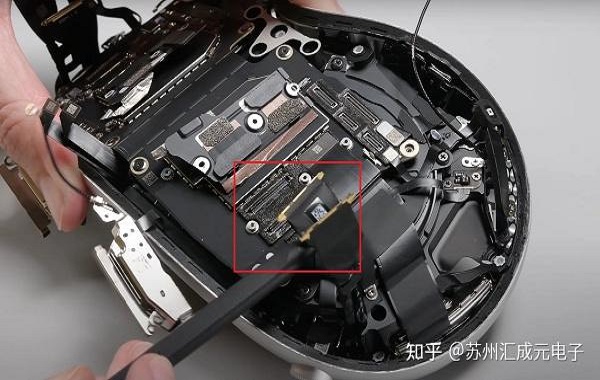

Vision Pro has very high requirements for the display system

Vision Pro's Micro-OLED screen has an extremely high pixel density, with each eye reaching a resolution close to that of a professional-grade display. Additionally, there is an EyeSight external display that needs to display the user's eye information in real time. This means that a large amount of image data must be transmitted internally, and the latency must be extremely low, with no image artifacts such as flickers, snow, or noise. Even just a few milliseconds of latency can affect the immersive experience, and even cause dizziness in users. Therefore, the internal cables of Vision Pro cannot just be "usable," but must have high reliability, high-speed transmission, and high anti-interference capabilities.

Based on common hardware architecture and industry design experience, the Vision Pro may use the following types of cables:

Extremely fine coaxial cableMost likely to bear the data channel of the key display screen, it may also be used for camera image signal. Possesses advantages of high speed, low loss and strong anti-interference ability.

Flexible Printed Circuit/Flexible Flat CableUsed for transmitting control signals, status information, backlight, or some low-speed functions. Light in weight, low in cost, and suitable for integration.

3. Shield the differential lineUsed for high-speed differential interfaces over short distances, such as certain sensors or auxiliary modules. It has better anti-interference performance than ordinary cables but is not as stable as coaxial cables.

The probability of using micro coax for the core image channel is very high, considering the semaphore, delay requirements, and anti-interference needs.

Why micro coax is a more reasonable choice

From the design logic of high-end head-mounted displays, the micro coax used for the Vision Pro's key display lines is very in line with engineering requirements:

Maintain high bandwidth and low distortion in a small space;The bendability and softness are high, suitable for the complex routing structure inside head-mounted displays.

3. EMI control is excellent, does not affect the sensor, wireless communication and other functional modules.

High structural stability, which helps reduce signal attenuation problems under long-term use.

Even though micro coax has a higher cost and more complex manufacturing process, for the Vision Pro, which is positioned as a flagship and pursues an ultimate experience, wire materials will never be a place to save costs.

I amSuzhou Huichengyuan Electronic Technology Co., Ltd., Long-term focus on the design and customization of high-speed cable harnesses and ultra-fine coaxial cable harnesses, providing customers with stable and reliable high-speed interconnection solutions. For consultation and cooperation, please contact:Manager Zhang 18913228573 (WeChat number same)。