Categorization:Harness Component

The importance of material selection

The ultra-fine coaxial cable needs to withstand high and low temperature environments, which first depends on the material used. Common materials such as PTFE (polytetrafluoroethylene) and FEP (fluorinated ethylene propylene) both have excellent temperature resistance properties. The typical temperature range of PTFE is about -65℃ to +200℃, and it is not prone to cracking or deformation when subjected to cold and hot temperature alternation. Such high-performance materials lay a stable foundation for the cable under extreme temperatures.

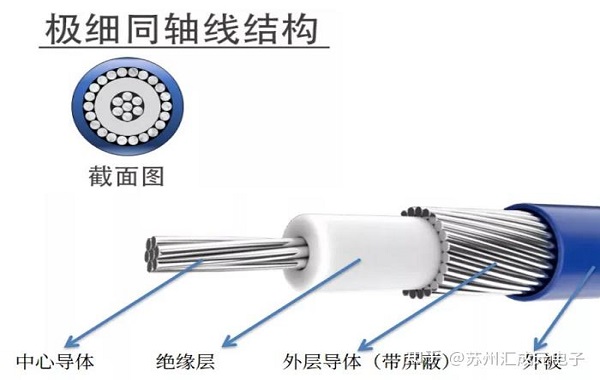

In the frequent changes of high and low temperatures, metal conductors will exhibit the phenomenon of thermal expansion and contraction. To ensure signal stability, extremely fine coaxial cables usually adopt silver-plated copper or nickel-plated copper conductors, which can maintain good conductivity while also improving temperature and corrosion resistance. At the same time, the woven shielding layer structure can effectively absorb stress changes, ensuring that the signal remains intact in complex environments.

The extremely thin coaxial cable has a small diameter and a precise structure. To maintain its lifespan under conditions such as bending, twisting, and temperature cycling, strict manufacturing processes are essential. For example, the control of the insulation layer thickness, the twisting accuracy, and the extrusion technology all directly affect whether the wire material will produce fine cracks during long-term use. High-quality craftsmanship achieves an ideal balance between flexibility and heat resistance for the wire material.

I am[Suzhou Huichengyuan Electronic Technology], Long-term focused on the design and customization of high-speed cable harnesses and ultra-thin coaxial cable harnesses, committed to providing customers with stable and reliable high-speed interconnection solutions. If you have any related needs or want to learn more, please contact:Manager Zhang 18913228573 (WeChat number the same)。