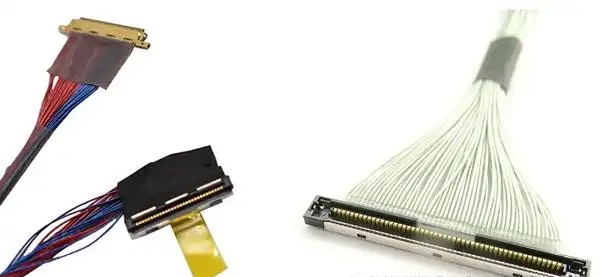

With the increasing demand for high-speed signal transmission and miniaturization in consumer electronics, medical imaging, drones, and vehicle-mounted cameras, ultra-thin coaxial cables (micro coaxial cable) have become the preferred choice for connection solutions due to their excellent signal integrity and flexibility. However, engineers and procurement personnel often encounter pitfalls in the purchasing process. This article takes the popular model Hirose DF80D-30P-0.5SD as an example to share experience in avoiding pitfalls in selection.

Introduction to Hirose DF80D-30P-0.5SD connector

Type

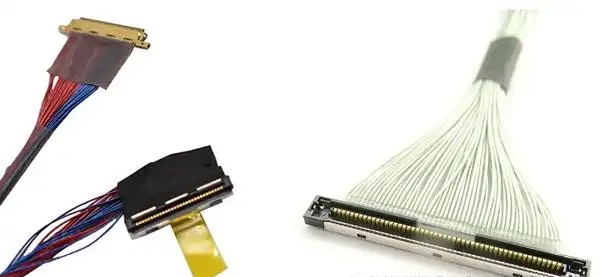

This connector belongs to the DF80 series Plug (plug) type, 30 pins, 0.5 mm pitch, supporting board-to-board or board-to-coaxial cable connections, and adopting a vertical mating (vertical mating) method.

Structural Design

Single row pin design, height of only about 1.72 mm, making the device thinner and more compact; equipped with a one-handed lock buckle and a clear "click" locking feel, ensuring easy and stable insertion operation.

Signal performance

Supports data transmission rates of up to 2.7 Gbps and 5.4 Gbps (compliant with eDP 1.3 HBR2 standard), with excellent signal integrity performance.

4. Compatible with cable and termination

Specifically designed for thin-wire micro coaxial cable (such as 40-46 AWG ultra-fine coaxial cable), each pin has a current tolerance of about 0.1-0.2 A; the center line needs to be soldered first, and then the shell kit (which requires an additional DF80-30P-SHL shell) is crimped on.

Material and Reliability

Adopt flame-retardant LCP plastic (UL94V-0), gold-plated gold contacts, and tin-plated stainless steel shell, with an environmental adaptability range of -35 ℃ to +85 ℃.

Part 2: Common pitfalls in purchasing ultra-fine coaxial cable bundles

Interface compatibility has not been confirmed

Micro coaxial cable specifications are diverse, it is necessary to confirm the wire diameter, number of cores, shielding layer, and terminal connector are precisely matched with DF80D-30P-0.5SD.

The transmission performance is neglected.

Some inexpensive wire harnesses cannot meet high-speed data transmission requirements; it is recommended to choose products that have passed EMI tests and TDR tests.

Insufficient supplier processing experience

The processing technology of extremely fine coaxial cable bundles is complex, and the welding, crimping, insulation, and braiding layer treatment have a significant impact on quality. Choosing the wrong supplier may lead to high repair rates and delayed delivery times.

Insufficient wire harness processing accuracy

The internal structure includes multiple insulation and shielding layers. If the stripping, welding, and crimping precision is not up to standard, it is prone to short circuits, loose welds, and poor impedance, which affects the signal quality and the reliability of the entire machine.

Lack of full inspection and key tests

Some suppliers, in order to reduce costs, omit TDR impedance tests, bend testing, and EMI shielding effect tests, leading to problems such as signal packet loss, loose interfaces, and poor anti-interference performance in field applications. When selecting suppliers, it is necessary to confirm that they have full factory inspections and complete test reports.

The selection and procurement of extremely thin coaxial cable assemblies are highly professional. It is recommended to choose a cable assembly factory with rich matching experience and qualified product testing. Especially for high-demand connectors like Hirose DF80D-30P-0.5SD, the quality requirements for cable matching are very high. Choosing the right supplier can significantly reduce risks and improve the reliability of the entire machine.

We have been focusing on the design and customization of high-speed cable harnesses and ultra-fine coaxial cable harnesses for a long time, committed to providing stable and reliable high-speed interconnection solutions. If you have any related needs or want to learn more, please contact: Manager Zhang.

18913228573(WeChat same number).