In today's rapidly developing world of high-speed signal transmission and miniaturized electronic devices, extremely thin coaxial cables (Micro Coaxial Cable) have become an indispensable key component in precision electronic connections. However, did you know that these cables cannot be焊接 arbitrarily, especially when using high-precision connectors like the I-PEX 20473-030T-10. Improper handling may directly affect the overall performance of the entire unit, and even lead to the scrapping of an entire batch of products!

What is a micro coaxial cable (Micro Coaxial Cable)?

Micro coaxial cable is a smaller, softer high-frequency transmission line material than traditional coaxial cables, with main features including:

Excellent signal integrity: Ensuring the stability of high-speed data transmission.

Suitable for high-resolution applications: capable of supporting high-speed signal transmission of video, data, etc.

Widely used in micro electronic products: such as laptops, camera modules, automotive systems, and medical equipment, etc.

Why can't the welding of extremely fine coaxial cables be "done随便"?

Many engineers or assemblers tend to treat ultra-fine coaxial cables as ordinary wires when they first encounter them, which often results in welding failures, abnormal signals, and even damage to the entire batch of connectors or motherboards. The main reasons include:

Extremely thin wire diameter, low tolerance rate

Micro coaxial cable core diameter is usually between 0.2mm–0.5mm (36AWG~42AWG), which is difficult to distinguish with the naked eye. The core is prone to breakage or cold solder joints with slight force or excessive temperature. During the soldering process, the iron temperature, soldering time, and the degree of downward pressure require extremely high requirements, making manual operation difficult to ensure consistency.

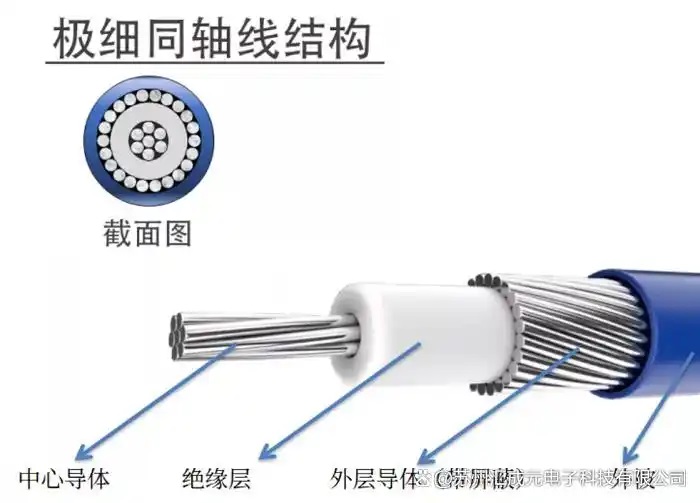

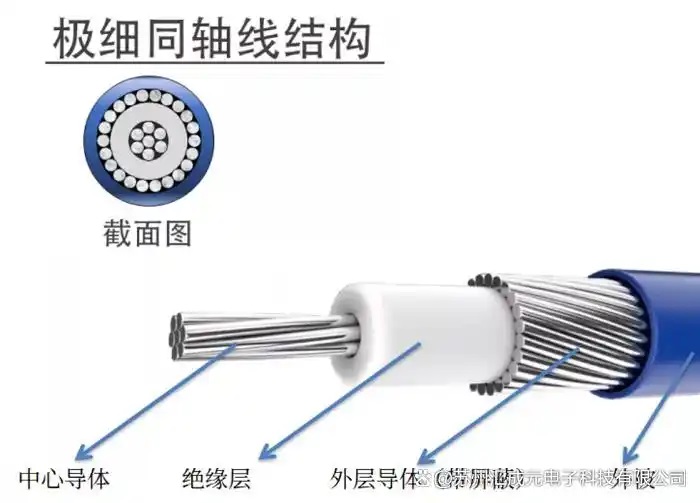

Multi-layer structure, prone to short circuit

The ultra-thin coaxial cable consists of a core conductor, insulation layer, braided shield layer, and outer sheath, all wrapped layer by layer. Overpeeling or improper operation is prone to short circuits, therefore, the peel length must be strictly controlled before welding, and each strip should be confirmed individually using a magnifying glass.

Soldering amount and temperature control requirements are strict.

Soldering too much: It is easy to cause multi-PIN bridging, short-circuit, or impedance abnormality.

Solder insufficient: poor soldering or poor contact, leading to signal interruption.

Low temperature: insufficient soldering, increased probability of cold solder joints.

High-frequency signal sensitive, solder joint quality affects performance

Micro coaxial cable is commonly used for high-speed signal transmission at 10Gbps/20Gbps. If there are problems such as cold solder joints, uneven solder quantity, or improper shielding, it may lead to signal reflection, impedance mismatch, increased EMI interference, and data transmission errors.

Introduction to I-PEX 20473-030T-10 connector

Basic positioning

• Belongs to the CABLINE®‑CBL series of miniature coaxial connectors.

Level plug housing structure, for use with the corresponding socket.

Supports 30 Pin mini coaxial cable connection, compatible with multiple extremely thin coaxial cables (AWG #40/#42/#44/#46).

Performance features

High-frequency high-speed transmission: supports interfaces such as eDP, V-by-One, USB 3.1 Gen1, with data rates up to 5 Gbps/line, and improved to 20 Gbps/line.

High-efficiency shielding and grounding: Shell shielding + multi-point grounding structure (ground bar), ensuring excellent electromagnetic compatibility (EMC) performance.

Soldering ultra-fine coaxial cables seems simple at first glance, but it actually requires extremely high technical expertise. It has strict requirements for equipment, process specifications, and operating environment. It cannot be soldered as carelessly as ordinary conductors. Only by relying on professional equipment, mature processes, and experienced technicians can stability of the connection and integrity of the signal be guaranteed, ensuring product reliability.

We have been focusing on the design and customization of high-speed cable harnesses and ultra-fine coaxial cables for a long time, committed to providing stable and reliable high-speed interconnect solutions. If you have any related needs or want to learn more, please contact: Manager Zhang.

18913228573 (WeChat same number)。