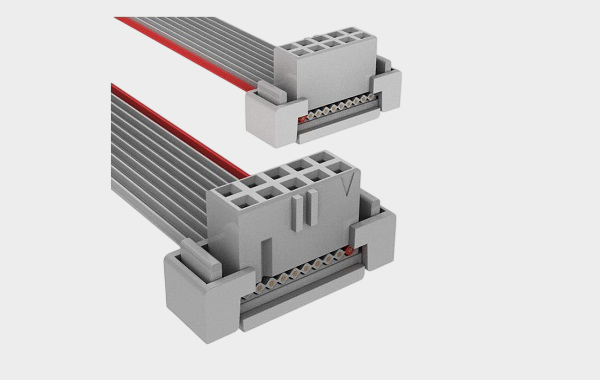

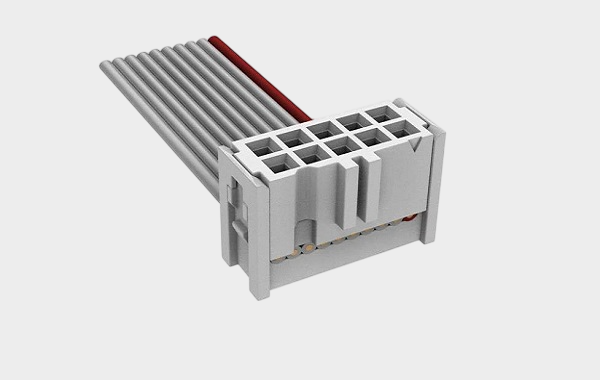

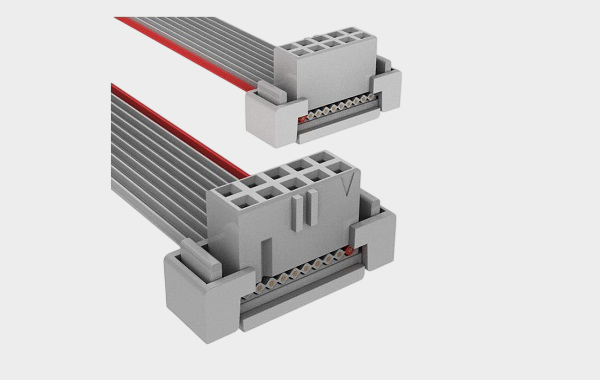

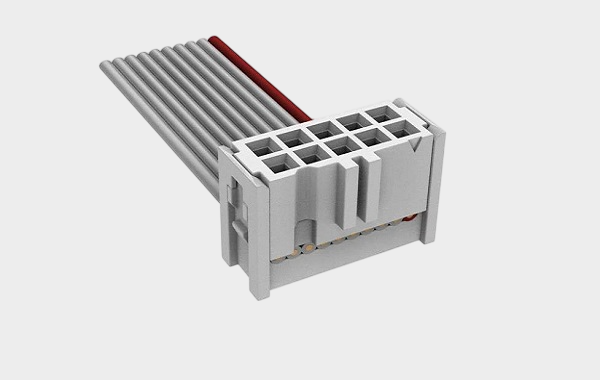

In the electronic equipment, industrial automation, automotive electronics, and communication industries, flat cables and rectangular cables are widely used due to their compact structure, flexible layout, and suitability for high-density interconnection. As an important brand in the global electronic interconnection field, 3M's flat cables, harness connectors, and IDC crimping technology have been adopted by the industry for a long time. However, whether the crimping process is compliant and the harness termination is excellent will directly affect the overall performance, stability, and lifespan of the connection system. Therefore, it is very necessary to understand the relationship between the crimping process and performance before choosing 3M harness products or corresponding domestic alternative solutions.

One, characteristics and crimping process of 3M flat and rectangular cables and the importance of the process

3M provides a variety of connectors for flat cables and rectangular cables, including Wiremount, IDC insulated displacement terminals, Mini-Clamp, Power Clamp, and a series of line-to-board, line-to-line, and branching connection products. These products are usually assembled using IDC or mechanical crimping methods, making assembly faster, safer, and reducing thermal damage caused by welding.

The crimping process plays a key role in the entire connection system.

Electrical performance impact

Good crimping ensures a tight contact between the conductor and the terminal, making the resistance lower and signal transmission more stable. In contrast, non-compliant crimping may lead to increased resistance, overheating, increased interference, and even signal loss.

Mechanical reliability affects

Regular crimping can enhance the vibration and tensile resistance of wire harnesses, ensuring that connectors do not become loose. Poor crimping may lead to faults such as wire breakage and poor contact during long-term use.

Insulation and safety impact

The IDC process must ensure that the insulation layer is not damaged, otherwise, problems such as leakage, short circuit, or reduced environmental tolerance may occur. Good crimping can prevent insulation damage and maintain system stability.

• System lifetime impact

High-quality crimping can extend the service life of the entire harness system and reduce maintenance costs; irregular crimping often leads to frequent failures later on.

Therefore, when using 3M flat or rectangular cable connectors, it is necessary to strictly follow the official termination requirements and ensure that the crimping tool, pressure settings, and operational procedures all meet the standards.

Two, selection and compatibility and alternative solution reference and suggestions

When choosing between 3M flat cables or rectangular cables for connection solutions, it is recommended to make judgments from the following perspectives, and you can also refer to domestic alternative solutions:

Select according to the cable specification

According to wire diameter, core number, flat wire pitch, etc., select the appropriate 3M Mini-Clamp, Power Clamp, or Link series connectors. The domestic substitute must match the same pitch, terminal structure, and rated current.

Select according to the application environment

If the internal space of the device is limited, the compact Mini series can be prioritized. If it is applied to machinery or power systems, products with stronger current-carrying capacity and higher mechanical strength, such as the Power Clamp series, can be chosen.

Compatibility alternative suggestions

Domestic manufacturers have developed alternative products that are compatible with 3M structures and interfaces, which are usually matched with IDC crimping methods and the same terminal layout. If cost control, improved supply stability, or response to the uncertainty of import cycles is a priority, such domestic alternative solutions should be considered first.

• Important reminder

Whether choosing original factory or domestic substitutes, strict electrical tests, tensile tests, and environmental tests should be conducted before mass production to ensure long-term stable operation in actual applications.

Whether it is flat cable or rectangular cable, 3M connector products have a high level of industry recognition in terms of design, technology, and stability. As the core link of the entire harness system, the crimping process has a direct impact on electrical performance, mechanical reliability, insulation safety, and service life. Against the background of global supply chain and the accelerated development of domestic substitution solutions, choosing the appropriate compatible substitute products and pairing them with standardized crimping processes will help customers achieve a balance between performance, cost, and supply cycle.

We have been focusing on the domestic substitution research and application development of 3M connectors and cables for a long time. If you are interested in domestic substitution solutions, have procurement needs, or are exploring relevant technical routes, welcome to contact: Manager Zhang.

18665383950, same number on WeChat). Looking forward to in-depth cooperation and communication with more customers and industry partners.