In the process of purchasing and supplying connectors, delivery time is one of the core elements that are on par with product performance and price. Especially in scenarios such as industrial automation, rail transit, and data communication, which are highly sensitive to delivery cycles, product delivery time directly affects the entire production plan and project progress. International connector brands like Amphenol CONEC have a comprehensive system in place to ensure delivery time. In the face of the global fluctuations in the supply chain and the trend of domestic substitution, an increasing number of customers are turning their attention to domestic connector products. So, how can domestic connectors establish a delivery guarantee mechanism and truly achieve stable supply?

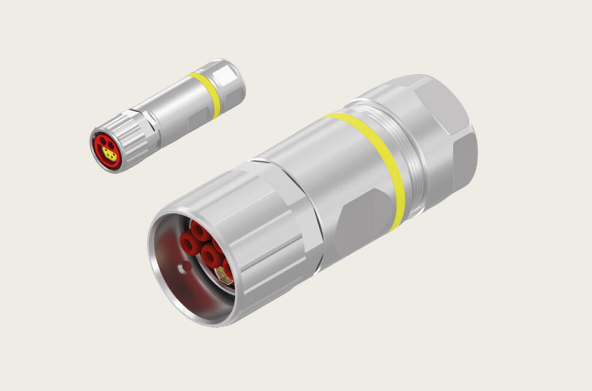

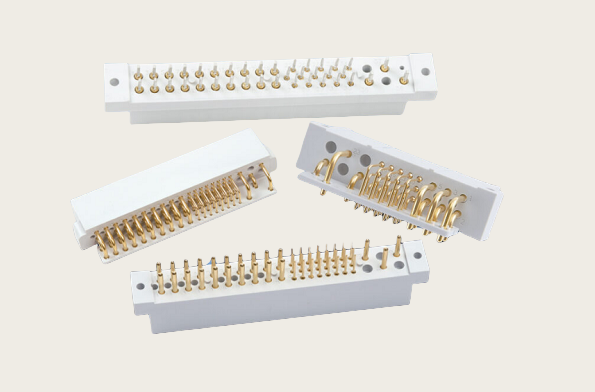

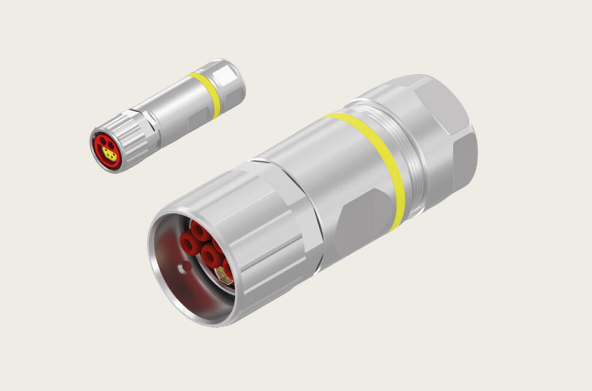

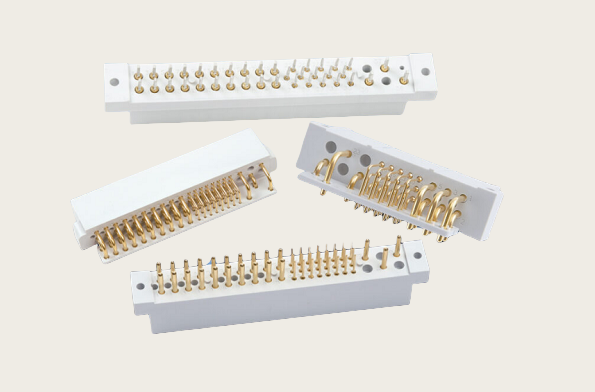

The delivery system characteristics of Amphenol CONECAmphenol CONEC is a well-known brand under the Amphenol group, focusing on the industrial connector field. Its main products include circular M8/M12 connectors, mixed D-SUB interfaces, and RJ45 industrial Ethernet connectors, etc. These products mainly serve the following industries:

Industrial automation

Communication equipment

●Medical electronics

Electric vehicles and charging systems

The delivery schedule system relies on highly automated manufacturing facilities, stable raw material supply channels, a global warehousing network, and systematic delivery plan scheduling, enabling it to have strong flexibility and controllability in the face of customers' large-scale and rapid delivery requirements.

Section Two: Challenges and Response Strategies for Domestic Connectors' Delivery TimelinesDomestic connectors often faced doubts about their reliability during the early development phase due to unstable deliveries and chaotic production schedules. However, in recent years, with the improvement of the industry chain maturity, some excellent domestic manufacturers have begun to establish professional delivery guarantee mechanisms.

Production capacity pre-positioning and conventional model inventory mechanism

Domestic high-quality manufacturers generally have a core model safety stock pool and dynamically adjust inventory levels based on customers' historical orders and industry rhythm to cope with sudden order demands or urgent project orders.

2. Multi-source material procurement strategy

By establishing a list of qualified suppliers, a parallel procurement mechanism is set for key materials such as plastic parts, metal shells, terminal pins, and springs, to reduce the risk of material supply disruption and improve the flexibility of the procurement cycle.

Flexible production and planning coordination system

Introduce MES system and ERP for integrated production planning management, achieving full-process visualization from order reception to scheduling and shipment, to avoid production line scheduling conflicts or resource bottlenecks.

4. Special delivery project management

For major customers and projects, a special delivery schedule guarantee team can be established to pre-lock raw material resources, production capacity, quality inspection, and logistics routes, realizing a "one-to-one tracking management" from order to delivery.

5. Combination of third-party logistics and local warehousing

Combine third-party logistics platforms with self-built regional warehouses to implement a 24-hour delivery response mechanism in key areas, effectively shortening the time span from dispatch to use.

Three, the delivery advantage of domestic connectors is gradually emergingWith the continuous optimization of the delivery mechanism, domestic connectors currently have a significant advantage in the delivery time of regular standard products. Most products can achieve a delivery cycle of 7 to 15 days, and some models can respond and ship on the same day. In terms of special customized products, modular design and process standardization can also ensure rapid delivery within a relatively short period of time.

In the context of global supply chain reconstruction, domestic connector manufacturers are enhancing their delivery capabilities through digitalization and systematic management methods, striving to upgrade from "price advantage" to a comprehensive "lead time + quality." When customers choose domestic substitute products, in addition to considering performance and cost, the guarantee mechanism for delivery time has also become an important reference standard for decision-making.

If you are interested in or have a procurement need for the domestic alternative products of this brand connector, or if you have a production or sales channel for such alternative products and wish to engage in in-depth cooperation or communication, please contact via the following contact information:

Manager Zhang (18665383950, same WeChat number)Contact us. We look forward to working with more industry partners to create a future with better delivery schedules and more stable supply!