Connectors play a crucial role in various communication and testing systems. However, whether it is imported brands like ConductRF or domestic connectors, some malfunctions may occur during use. Understanding these common problems and taking effective preventive measures is the key to improving system stability and lifespan.

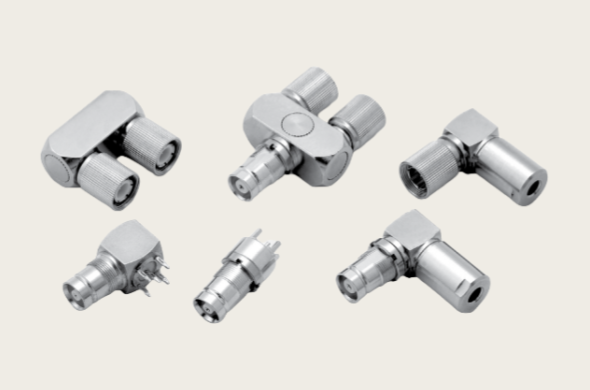

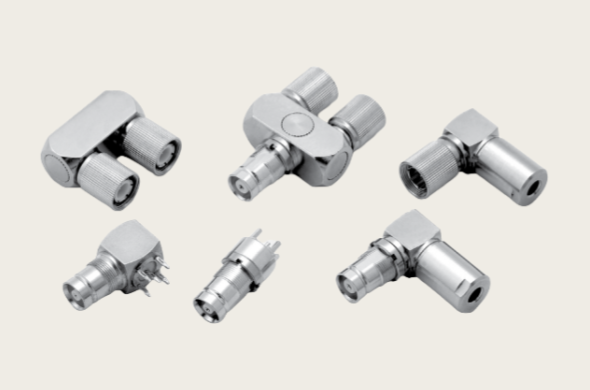

ConductRF Brand Overview and Quality AdvantagesConductRF is a brand of Electronic Assemblies Mfg. Inc. in the field of RF interconnects, with over 20 years of experience. Its products cover standard and precision RF connectors, test RF cables, support customized designs, and have complete capabilities in high-frequency performance and reliability testing (such as bend testing, low insertion loss, phase/temperature stability, PIM testing).

In addition, ConductRF performs 100% performance testing on each component to ensure that the connector meets high standards in terms of mechanical fatigue, VSWR, insertion loss, etc.

Common Faults and Prevention Suggestions for Domestic ConnectorsThe following are the common problems faced by RF connectors (including domestic ones) in actual use, as well as the protective measures that can be referenced:

1. Contact Failure (Poor Contact) and Open Circuit Issues

Frequent plugging and unplugging can cause spring parts to lose elasticity, metal surface wear, or corrosion affecting contact stability, which may lead to open circuit or poor contact.

Preventive suggestions: Use wear-resistant materials (such as gold plating), regularly clean the contacts, reduce frequent plugging and unplugging, and apply a thin layer of conductive grease when necessary to reduce wear and oxidation.

Loose connections, thread failure, and mismatch

●Common domestic connectors may be loose or unable to be tightly fastened due to manufacturing tolerances or incomplete thread design, leading to signal reflection or poor connection.

Preventive suggestions: Ensure the connector matches the model, use a torque wrench to control the tightening force, and choose materials that are designed reasonably and have good elasticity.

3. Internal conductor loose or structural damage

If the internal conductor is not properly assembled or bonded, it may become loose or broken after multiple insertions and extractions; insufficient structural stability will also exacerbate this problem.

Preventive suggestions: Use conductive adhesive or thread locking agent of appropriate strength during assembly, and improve the structural design to enhance stability.

4. Increase in reflection and impedance change

●Insertion and removal temperature changes can cause deformation of the medium material, affecting impedance consistency and reflection loss, especially in high-frequency application scenarios.

Preventive suggestion: Use phase/temperature stable materials, and refer to the experience of controlling material properties of imported products (such as ConductRF).

Pollution and corrosion

In damp or saline environments, the contact surface is prone to form an oxide layer or corrosion, leading to an increase in contact resistance and signal attenuation.

Preventive suggestions: Choose corrosion-resistant materials (such as three-layer plating: copper-nickel-gold), enhance protective sealing design, and regularly inspect and clean in environments with high humidity.

Frequent plugging and unplugging leads to wear accumulation

Excessive insertion and extraction not only wear metal components and reduce contact quality, but may also affect frequency response and signal integrity.

Preventive suggestions: In the process of structural design or maintenance, reasonably plan the frequency of insertion and extraction. If frequent insertion and extraction are necessary, higher life expectancy materials or spare connectors can be used.

Domestic connectors have obvious advantages in cost and local service response, but to improve their reliability, it is necessary to continuously optimize from aspects such as structural design, material selection, assembly technology, and test verification. Referencing the high-standard quality control and testing processes of leading brands such as ConductRF is an effective approach to enhance the overall performance of domestic connectors in terms of performance stability, durability, and environmental adaptability.

If you are interested in the domestic substitute products of ConductRF brand connectors, or have procurement needs, or own production or sales channels for such domestic substitute products, and wish to further cooperate or communicate, please contact:

Manager Zhang (18665383950, same WeChat number)We look forward to working with more industry partners to promote quality improvement and win-win the future.