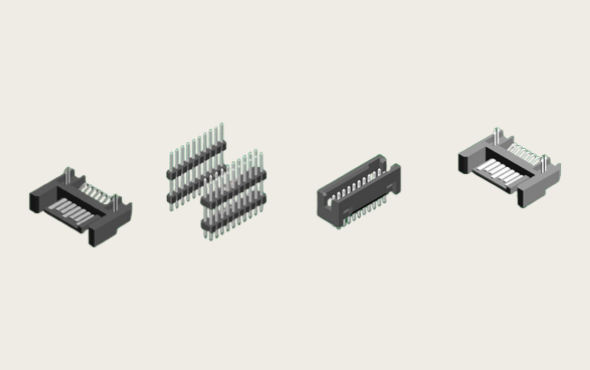

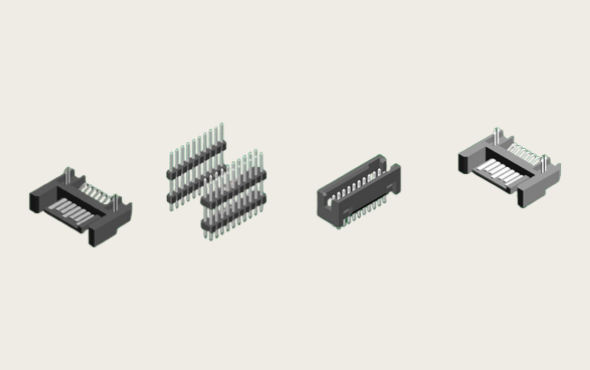

E Connector Solutions (简称 ECS), originating as a contact supplier since 1979, has developed into a complete connector manufacturer integrating research and development, mold design, injection molding, stamping, and assembly. Its "can-do" spirit enables it to undertake many complex connector projects that others cannot mass produce, serving widely in fields such as telecommunications, medical, and military. ECS adheres to independent design and self-built tooling molds, including injection molds and stamping molds, and is equipped with high-quality injection and stamping equipment, which provides a strong guarantee for the consistency of quality in the production process.

Typical process flow and key quality control points in the production of domestic connectorsIn connector manufacturing, the following core processes are usually involved:

●Stamping: Metal strips are processed on a high-speed press to form terminal and contact shapes.

●Electroplating (Plating): Treating metal contacts with gold plating, nickel plating, etc., to enhance conductivity and corrosion resistance.

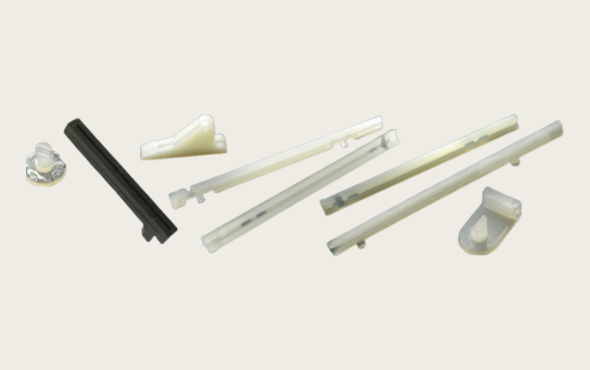

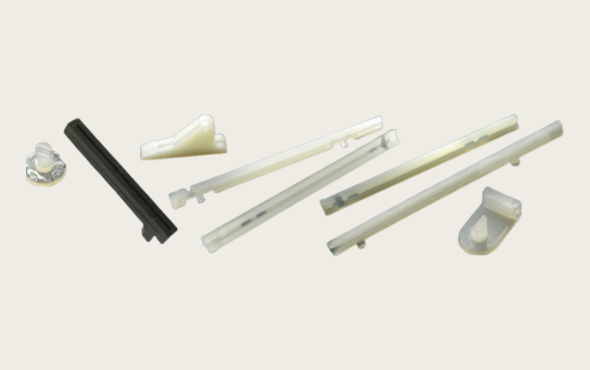

●Injection Molding: Injecting plastic melt into a mold to produce connector shells and insulators.

●Assembly: Insert terminals into the housing, align and fix them, and then add structures such as cables and shells.

●Testing & Inspection: including functional testing, mechanical durability, appearance inspection, dimensional measurement, etc.

Control quality at each stage to ensure the final product's performance and consistency.

Suggested quality control measures for the practice of ECS (Elastic Compute Service)Based on the advanced manufacturing system of ECS and the actual situation of domestic connectors, the following quality control measures are particularly valuable for reference:

Autonomous mold design and maintenance

ECS independently designs and centrally manages molds to ensure mold accuracy and consistency in maintenance, reducing quality fluctuations in products caused by mold deviation.

2. Precision production equipment investment

Invest in high-performance injection molding machines (such as Toshiba equipment used by ECS), stamping equipment, and配合 fine process parameters to ensure stable quality of plastic parts and metal components.

Surface Quality Control

Precision electroplating of the contact point ensures low contact resistance and anti-oxidation properties, reducing open circuit and contact failure situations.

4. Strict assembly and automated detection

During the assembly process, visual or machine-assisted inspections are used to check for defects such as misassembly, missing parts, and misalignment. For example, AI machine vision can be referred to for automatic detection of housing defects, misalignment, contamination, and so on.

5. Factory test and aging inspection

Covering electrical continuity, voltage resistance test, mechanical insertion and extraction life, and cold and hot and wet cycle tests, hidden defects were found and eliminated.

6. Full-process quality traceability system

It is suggested to establish a digital traceability system from raw materials, production batches, test data to shipment records to enhance continuous optimization and problem response capabilities.

If domestic connectors are to maintain their position in the market competition, they must strengthen the quality control process, starting from each link in the process, from "independent mold design→precision production equipment→assembly testing→quality traceability", and create a systematic and traceable manufacturing process. Learning and referencing ECS's complete manufacturing capabilities and quality strategy is the key path to improving the reliability and market recognition of domestic connectors.

If you are interested in the domestic alternative products of E Connector Solutions brand connectors, or have relevant procurement needs, or have production or sales channels for such domestic alternatives, we would like to engage in in-depth cooperation and communication with you. Welcome to contact us at any time: Contact person:

Manager Zhang (18665383950, same WeChat number)We look forward to working together with industry partners to create value.