One, the quality genes of Encitech ConnectorsEncitech is a Swedish connector manufacturer with over 40 years of experience, specializing in the design, production, and distribution of connectors and jackets for cable and board applications. Their products are widely used in various fields such as industry, communication, rail transportation, medical care, and more. Their product line includes high-quality D-Sub jackets, D-Sub kits (including connectors and shells), industrial-grade USB connectors (IP68 protection level), and more.

Section 2: Key Parameters for Quality Inspection of Domestic ConnectorsIn combination with industry common standards and practical experience, the domestic connector that successfully replaces the Encitech product needs to pay attention to the following core inspection indicators:

Appearance and Dimensional Accuracy

●外观 inspection: Observe the surface visually or under a microscope for scratches, deformation, rust, and other defects.

●Size inspection: Use calipers, projectors, and other tools to measure the length, width, pin pitch, etc. of the connector to ensure they meet the design requirements.

Electrical performance indicators

Contact Resistance: Ensure good connection performance, reduce signal loss and electrical thermal risks.

Insulation resistance: verifies insulation characteristics and ensures safety under high temperature and humid conditions.

● Voltage Withstand Test (Insulation Voltage Resistance): It detects the stability and breakdown resistance of the connector in overvoltage environments.

Mechanical property test

Execute in accordance with industry common standards (such as the EIA-364 series).

Insertion/Withdrawal Force Test

●Durability Test (number of insertion/extraction cycles)

● Vibration and mechanical shock testing.

Environmental reliability test

Temperature and humidity cycle test: inspect the adaptability under high and low temperature and humid environments.

Salt spray corrosion test: Evaluate the service life and reliability of connectors in corrosive environments.

●Accelerated aging test: Simulating performance changes after long-term use through extreme conditions.

5. Shielding and anti-interference ability

For metal sheath or shielding connectors, it is necessary to verify the EMI/RFI (electromagnetic/radio frequency interference) shielding effect to meet the requirements, ensuring signal quality and anti-interference capability.

Compliance and Quality System

Encitech and other brands usually adopt quality system standards such as ISO/TS 16949 or DIN EN ISO 9001 for production management to ensure the traceability and stability of product quality.

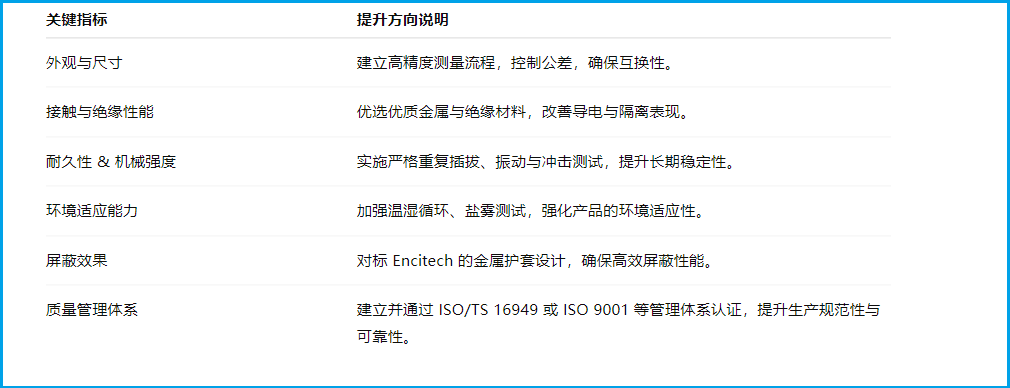

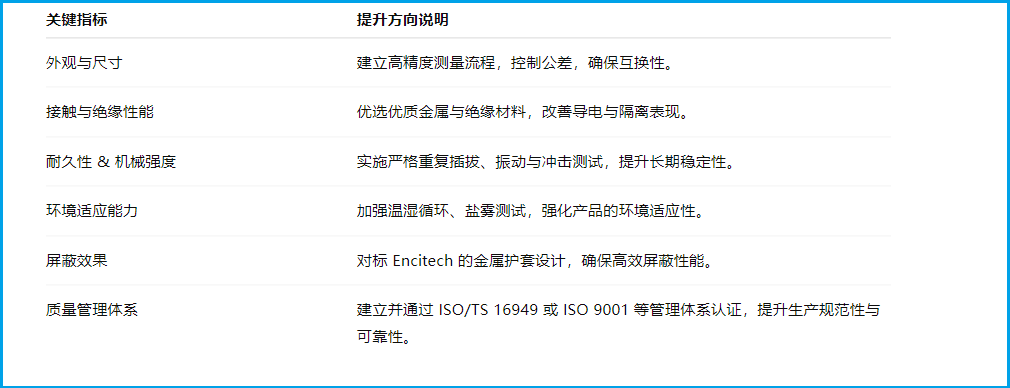

Thre、Suggestions for the direction of domestic substitution enhancement

Encitech Connectors has established a high standard in the market with its rich models, excellent materials, and rigorous quality system. For domestically produced connectors to successfully replace imported excellent brands, they must comprehensively improve in multiple dimensions such as appearance size, contact and insulation performance, durability and mechanical properties, environmental stability, and shielding ability, and ensure this through a mature quality management system. Only in this way can domestic replacement truly take into account performance, reliability, and cost-effectiveness, and win market recognition.

If you are interested in domestic alternatives to Encitech Connectors brand connectors, or have related procurement needs, production or sales channels, and wish to engage in in-depth cooperation or communication, welcome to contact

Manager Zhang (18665383950, WeChat number the same)We look forward to joining hands with more industry partners to move forward together and create value.