In the high-end connector field, ODU is a globally renowned German manufacturer. Its products are widely used in key industries such as military, medical equipment, industrial automation, energy, and transportation due to their reliable push-pull locking technology, modular design, and excellent durability. With the continuous growth of domestic substitution demand, domestic connector enterprises are constantly catching up in terms of technological research and development and quality control, but still face some technical difficulties in quality improvement.

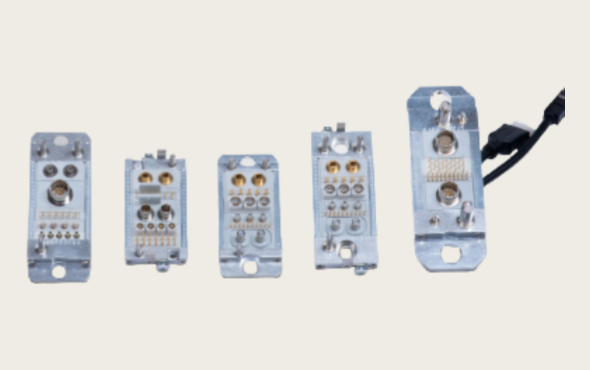

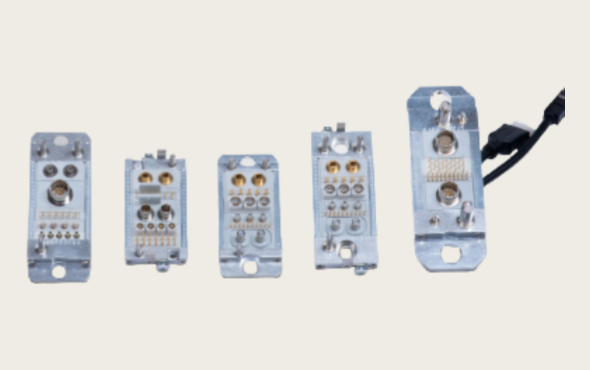

One, technical advantages of ODU connectorsThe core advantages of ODU are mainly reflected in:

● High-reliability contact piece design: Ensure long-term stable electrical performance;

Precision structural technology: The tolerance control between the shell and the pin is extremely strict.

●Robust environmental adaptability: maintains stable performance under extreme conditions such as high temperature, strong vibration, and high humidity.

●Modularization and customization capabilities: meet the diverse needs of complex scenarios such as military and medical fields.

These features make ODU a benchmark in the high-end market and also become the "technical high wall" that domestic manufacturers must cross in the process of catching up.

The technical difficulties in improving the quality of domestic connectorsInsufficient contact piece reliability

Domestic substitute products still lag behind imported brands in terms of insertion and extraction life, contact resistance stability, and electromagnetic shielding effect.

Material and surface treatment gap

ODU and other international manufacturers have long-term accumulation in alloy formulation, electroplating technology, and anti-corrosion treatment, while domestic enterprises still need to improve in consistency control and batch stability.

Precision manufacturing and tolerance control

High-end connectors have extremely high requirements for micron-level processing accuracy and consistency, which requires support from advanced molds, combined turning and milling equipment, and automated detection systems.

4. Verification capability under extreme conditions

The application environment in military, aerospace, and other fields is extremely complex, requiring completion of a series of international-level verifications, including high and low temperature cycles, salt mist corrosion, vibration and shock, etc. However, domestic enterprises have insufficient investment in verification systems and testing equipment.

Three, future breakthrough directions● Material localization and new alloy research and development: promoting independent control of basic raw materials.

● Surface Treatment and Electroplating Technology Upgrade: Improve corrosion resistance and conductivity stability;

Automation and Intelligent Manufacturing: Improve product quality and consistency.

●Third-party authoritative certification: Strengthen alignment with international standards and enhance recognition of domestic brands.

Domestic connectors have made breakthroughs in the process of replacing international brands such as ODU in the mid-to-low and some mid-to-high-end markets. However, in order to comprehensively improve quality and achieve true import substitution, it is necessary to continue to make breakthroughs in multiple links such as contact piece reliability, material technology, precision manufacturing, and testing and verification.

If you are interested in the domestic alternative products of this brand connector or have procurement needs, or if you have production or sales channels for the domestic alternative products of this brand connector and wish to engage in in-depth cooperation or communication, please contact via the following contact information:

Manager Zhang (18665383950, same WeChat number)Contact us, we look forward to working together with more industry partners.