In the electronics and automotive industries, connectors, as core components, directly affect the production and delivery of products. In recent years, the global supply chain has faced multiple challenges, leading to delayed delivery of connectors becoming an urgent problem for enterprises to solve. UJU, as a well-known connector brand, provides effective solutions with its strong production capacity and comprehensive after-sales service.

The main reasons for the delay in delivery of connectorsMaterial shortage: The price of raw materials such as copper, steel, and thermoplastic plastics has increased, leading to supply tension and extended production cycles.

Shortage of labor: The global manufacturing industry is普遍 facing a lack of labor, which affects production efficiency.

Logistics bottleneck: transportation delays and port congestion lead to the inability of raw materials and finished products to arrive on time.

Demand surge: With the rapid development of industries such as smart devices and new energy vehicles, the demand for connectors has surged, exceeding production capacity.

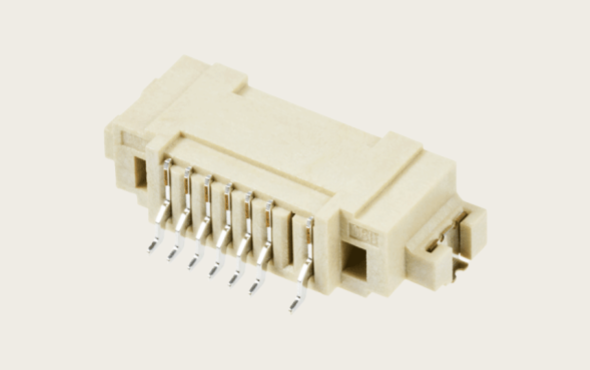

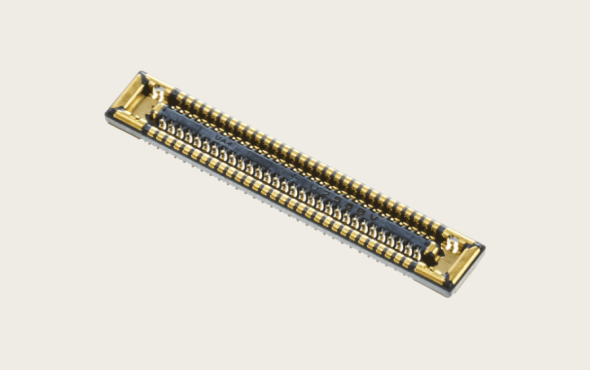

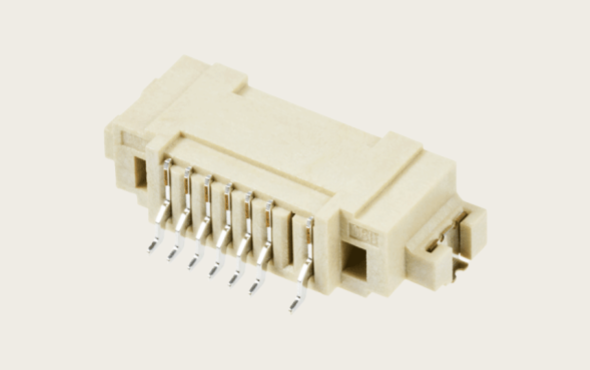

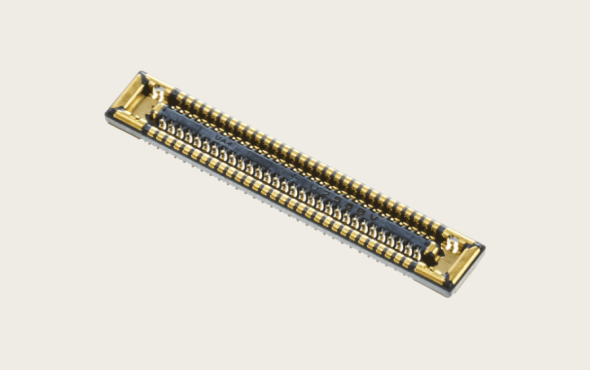

The response measures of the UJU brandUJU Electronics Co., Ltd. was established in 1993, focusing on the research and development and production of high-precision miniature connectors. The company owns advanced automated equipment and a professional engineering team, capable of responding quickly to market demand.

Provide a domestic alternative solution

In response to the issues of long lead times and high costs for imported connectors, UJU offers domestic alternatives to ensure that customers can obtain the required connectors in a short period of time and reduce procurement costs.

Localization technology support

UJU has service centers in many regions, providing localized technical support and after-sales service to ensure that customers' problems can be resolved in a timely manner during use.

Flexible production scheduling

UJU adjusts production plans flexibly according to market demand and customer order situations, prioritizing urgent orders to shorten the delivery cycle.

Strict quality control

UJU strictly implements quality control standards in the production process to ensure the stable quality of each batch of products and reduce rework and delays caused by quality issues.

Three, practical application casesIn the new energy vehicle industry, UJU's car connectors are widely used in battery management systems and on-board charging modules. Through close cooperation with customers, UJU has successfully shortened the delivery cycle and ensured the smooth progress of the projects.

Connector delivery delays are a common problem in the current supply chain, and choosing a reliable supplier is crucial. UJU, with its strong production capacity and comprehensive after-sales service, can effectively deal with delivery delays and ensure that customers' production plans are not affected.

If you are interested in the domestic substitute products of the UJU brand connectors, or have procurement needs, or have production or sales channels for domestic substitute products of UJU connectors, and wish to engage in in-depth cooperation or communication, please contact us through the following contact information:

Manager Zhang (18665383950, same WeChat number)We look forward to working together with more industry partners.