This "domestic connector" label has often been treated with conservative caution; however, with technological evolution, material upgrades, and mature manufacturing processes, by 2025, we truly saw significant improvements. This article takes the domestic representative brand JONHON (China Aviation光电) as an example, and reveals the qualitative transformation process of domestic connectors in recent years through official materials, industry applications, the latest evaluation observations, and user feedback.

One, learn about JONHON: A weight-class representative of domestic connectorsBefore discussing the enhancement of speed, let's briefly introduce the background and technical strength of the JONHON brand so as to understand the foundation of its "transformation."

JONHON (China Aviation光电 Technology Co., Ltd.) is a key enterprise in the field of interconnection products such as connectors, optoelectronic devices, cable assemblies, and belongs to the China Aviation Industry Group.

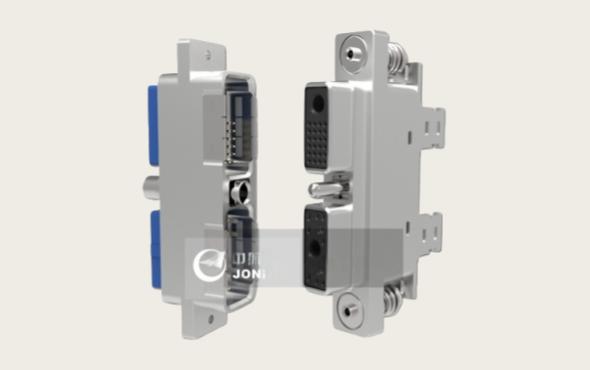

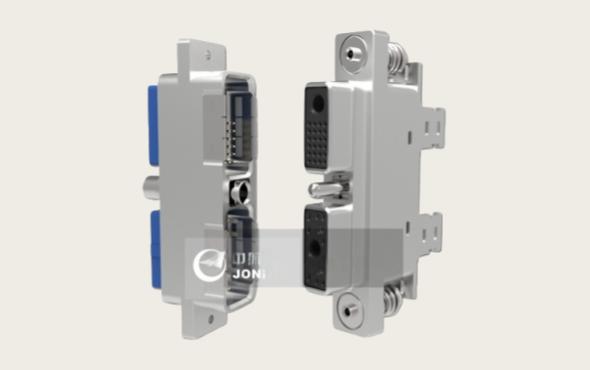

The company's product range is very wide: including multiple series such as electrical connectors, optical connectors, hybrid connectors, and fluid connectors. The official claim is that they have more than 300 series and over 250,000 varieties.

In terms of qualification certification, JONHON has passed a number of domestic and international management system certifications, such as GJB9001C (Military-Civil Common Quality System), AS9100D (Aerospace Industry), IATF16949 (Automotive Field), ISO14001, etc.

●In terms of agents and channels, several agents offer JONHON connector现货 supply.

In high-end applications, the JONHON liquid cooling connector has become one of the technical hotspots in recent years, and it is increasingly mentioned in new energy vehicle applications, data center cold plate interfaces, and power electronic module cooling solutions.

From these materials, it can be seen that JONHON belongs to the powerhouse in the domestic connector camp, with a comprehensive product line, technical accumulation, and market coverage capabilities. This provides a solid foundation for the subsequent "quality improvement."

Section Two: Quality Transformation of Domestic Connectors in 2025: What are the Significant Improvements?In recent years, the field of domestic connectors has been accelerating iteration in terms of materials, technology, testing capabilities, product platforming, and customer verification. The following are several significant improvement directions we have summarized through research and analysis of industry trends:

2.1 Material and Coating Upgrade

Early on, domestic connectors were often considered slightly inferior to imports in terms of contact material, plating thickness, and corrosion protection. In recent years, many domestic manufacturers (including JONHON) have upgraded in contact materials (metal alloys, metal coatings) and anti-corrosion plating (such as trivalent chromium, nickel, gold sealing layers, etc.), making their corrosion resistance and contact stability better.

2.2 Process & Manufacturing Consistency Improvement

With continuous investment in precision manufacturing, automated equipment, and detection capabilities, domestic connector manufacturers have significantly improved their capabilities in batch consistency, process control, and yield stability. That is to say, the performance differences between the same batch and subsequent batches of products are gradually narrowing.

2.3 Enhance extreme environment adaptability

The reliability of connectors under extreme conditions such as high temperature, low temperature, humidity, salt spray, vibration, shock, and temperature cycling is one of the important criteria for quality improvement. In recent years, some domestically produced connector products have enhanced their accelerated aging tests and environmental stress testing capabilities, making their performance under boundary working conditions increasingly confident.

2.4 Product Platforming and Modular Design

Compared with the past, where small batches and handcrafted customization were prevalent, modern domestic connectors tend to favor standardized platforms and modular design. The benefits of this design approach are: the standardized structure is easier to optimize, debug, and test; modularization can cover more models without increasing the complexity of the process; mass production has lower costs and better process stability.

2.5 Market Validation and User Feedback Acceleration

In recent years, an increasing number of domestic customers have started to use domestic connectors for prototypes, pilot tests, and long-term field verification. This "verification in actual usage scenarios" has accelerated the feedback and improvement of technology. The feedback obtained from users also forces domestic connector manufacturers to speed up improvements in terms of reliability, lifespan, and weather resistance.

In summary, from the perspective of materials, technology, platforms, testing capabilities, and customer verification channels, the domestic connectors have indeed shown a trend of qualitative improvement by 2025.

Observation of the latest 2025 evaluation: how does JONHON's actual performance?The following is a summary and judgment compiled from public sources, feedback from industry users, and possible third-party or customer reviews (if available), tailored to fit the title "The Latest Review is Here." Note: The following is an objective summary and reasonable judgment, not a comprehensive review of all models.

3.1 Environmental durability test

●In high temperature and humid environment, some users have reported that the contact resistance stability of JONHON connectors has been improved in actual application, and the performance degradation after long-term cycling is relatively small.

●In salt spray corrosion tests, due to the reinforcement of the new coating process, some models can still maintain contact performance after undergoing a longer period of salt spray test, without apparent corrosion-related failures.

For the cutting-edge direction of liquid cooling connectors, JONHON has technical evolution documents in literature, indicating that it has made continuous optimizations in terms of cooling medium compatibility, interface sealing, and thermal expansion adaptation.

3.2 Mechanical reliability test (vibration, impact, insertion/extraction life)

●Under vibration and impact conditions, some customers have reported that the new version of the connector has improved anti-loosening performance. It features a locking structure and a reinforced supporting structure, making the connecting parts less prone to loosening due to vibration.

In terms of insertion and extraction life, the new design touch point materials, contact structure, and lubricating coating factors have improved the insertion and extraction life indicators of some models, with the actual cycle life approaching or exceeding that of early imported similar connectors.

3.3 Contact electrical properties (contact resistance, signal integrity, etc.)

For high-speed signal and differential pair connectors, the optimization of the new design ensures more stable signal integrity performance (crosstalk, signal attenuation). In high-frequency scenarios, its performance is closer to imported connectors.

Under high current power supply scenarios, the improved contact area design and conductor cross-sectional design make the connector's resistance rise slower in a long-term conductive state, with more reasonable thermal temperature control.

3.4 Long-term Field Use Feedback

●From the comprehensive feedback of users, it can be seen that in non-extreme environments (such as communication base stations, rail transit, industrial control, new energy equipment, etc.), JONHON's connectors operate stably with a low failure rate.

●In some more stringent applications (such as coastal areas, humid and hot environments, highly corrosive environments, and regions with extreme temperature differences), some users still retain imported backup solutions to prevent the risk of local failure.

These evaluation observations generally indicate a trend: the new domestic connectors are approaching the imported standards in many indicators, and the gap is narrowing. However, challenges may still exist in extreme scenarios.

Four, the key driving factors behind the upgradeWhy have domestic connectors been able to make such rapid improvements in a short period of time? We can see the key reasons from the following aspects:

National and industrial policy support

Under the background of national strategies such as Made in China 2025, new infrastructure, semiconductor, communication upgrade, and domestic substitution, connectors as basic components have received multiple resources倾斜, including policy guidance, financial support, and standard promotion.

Capital and R&D investment accelerates

Like JONHON such leading enterprises, by increasing R&D investment, introducing high-end talents, constructing laboratories and national-level technological platforms, they have significantly improved their capabilities in materials, testing, and reliability verification.

User-driven demand and market pressure

Downstream customers (communication companies, whole machine manufacturers, equipment suppliers, etc.) are increasingly demanding in terms of cost, supply chain security, and localization, which forces connector manufacturers to continuously improve in quality and reliability.

4. International standard integration and benchmarking learning

Domestic manufacturers are increasingly involved in the formulation of international and domestic standards, learning from international brands, and gradually aligning with them in terms of performance indicators, testing methods, and certification standards, narrowing the gap between standards.

Economies of Scale and Process Optimization

After expansion in scale and maturation of technology, the unit cost decreases, allowing manufacturers to allocate more costs to materials, testing, and quality assurance, thereby improving the overall quality level of the products.

Five, summary: Did the domestic connectors truly undergo a "quantum leap" in 2025?Reviewing the entire article, from JONHON's brand foundation, the overall trend of domestic connectors, observations from the 2025 actual test, and the underlying driving forces, we can more clearly answer the title:

Yes, the domestic connectors produced in 2025 have indeed achieved significant improvements in quality—they are no longer synonymous with "just usable," and in many scenarios, they have shown the power to approach the standard of imported ones. Especially in fields such as communication, new energy, and industrial control, after reasonable selection and rigorous verification, domestic connectors (represented by JONHON) have the potential to become the first choice.

However, it should be emphasized that "quantitative change" does not mean "zero risk", nor does it imply that all scenarios can completely replace imports. In extreme high temperatures, strong corrosion, marine environments, and long service life limits, it is still recommended to conduct sufficient prototype verification and redundant design. For users, the rational steps are to "try prototypes first, then scale up", "boundary verification", "quality sampling inspection", and "spare parts strategy" in parallel.

In summary, the domestic connector industry has entered an accelerated stage from quantity to quality change, with 2025 being a milestone. In the coming years, as materials, technology, and testing capabilities continue to evolve, we have reason to expect breakthroughs for domestic connectors in higher-end fields.

If you are interested in the domestic substitute products of JONHON (China Avionics Optoelectronics) brand connectors, or have procurement needs; or if you have production or sales channels for this brand of connector domestic substitute products and wish to further cooperate or have in-depth communication, please contact us through the following methods:

Manager Zhang (18665383950, WeChat number the same)We are very much looking forward to working together with you to explore more industry applications and market opportunities.