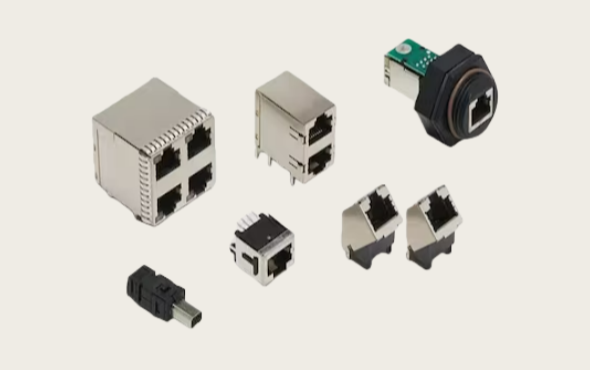

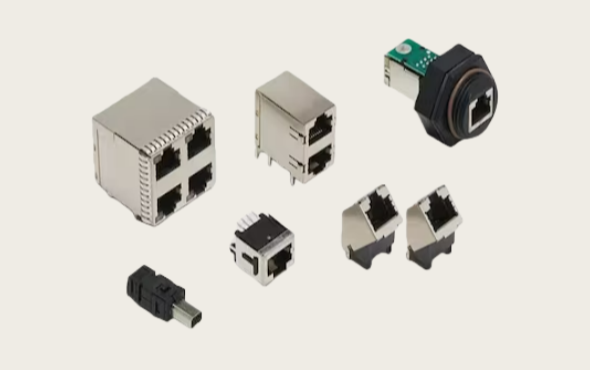

In connector selection and supply chain management, a question that is increasingly frequently raised is: Can we "test the waters" by adopting **domestic connectors to replace imported brands** in the project? When it comes to high-end connectors, ERNI is a name that cannot be bypassed: its products are renowned for their high density, small spacing, high-speed signals, and high reliability.

For example, ERNI's MicroCon series supports compact double-row connectors with a spacing of 0.8 mm; its MicroSpeed series supports high-speed data transmission up to 25 Gb/s. These technical parameters can be found in many industrial, vehicle-mounted, data center, and automated equipment.

Then, is it feasible to completely replace ERNI or similar high-end brands with domestic connectors in the project? We will explore this from the following dimensions.

ERNI Technology Analysis: Why is it widely adopted?1. Micro pitch and high density: ERNI's MicroCon series is designed with a 0.8 mm pitch, making it suitable for board-to-board, sub-module connections, and scenarios where space is limited but signal requirements are high.

TE Connector

High-speed data performance: The MicroSpeed series can achieve high transmission rates while maintaining excellent signal integrity, which is very critical in high-speed interconnects, data collection, and transmission modules.

High reliability and stable structure: its product line covers signal, data, and power connectors, with good performance in details (insertion and extraction life, vibration resistance, mechanical strength).

Widely used: including automation, transportation, communication, medical, vehicle-mounted and other fields. Its brand background and technical accumulation make it the preferred choice for many projects.

These advantages collectively contribute to ERNI's "golden status" in the connector field. However, due to its high-end brand positioning, its cost, supply cycle, and customization flexibility may become restrictive factors in projects.

Is it worth considering "National Production Connector Replacement" in the project?When a project considers "domestically produced alternative connectors," it means migrating or replacing from imported brands (such as ERNI) to completely domestic brands. There are potential opportunities as well as challenges that must be overcome.

Opportunity:

Cost advantage: Domestic connectors can provide more competitive prices in most cases.

●Localization of supply chain: local manufacturing responds faster and has more flexible delivery schedules, which is particularly beneficial for rapid iteration or prototype stages.

Customization and Flexibility: Domestic manufacturers may be more attuned to user needs in terms of customized services, flexible production, and coordination of layouts.

Challenge:

Whether the technical indicators can fully meet the requirements of ERNI in terms of spacing, miniaturization, high-speed signals, insertion/extraction life, and compatibility?

●Signal integrity and reliability verification: High-speed data or high-frequency applications must strictly control insertion loss, return loss, crosstalk, EMI/EMC, and these are often "breakthrough points" in domestic substitution.

●Certification and Brand Trust: Many high-end projects still prefer to use international brands for verification first, and then gradually consider domestic alternatives.

Project risk management: If domestic substitution is adopted, there must be contingency plans and risk control measures, such as interface compatibility failure, poor reliability, weak after-sales support, etc.

Therefore, "testing the waters of national connection products" in the project is not an overnight success, but a step-by-step process of advancement, verification, and application.

Three, recommended "trial and error" ideas: project implementation pathWe recommend the following approach for enterprises or teams looking to try domestic connector replacements for ERNI in their projects:

1. Identify modules and interface types: Start with modules in the project that have more general interface requirements, relatively controllable risks, and cost sensitivity. Compare with the corresponding interface specifications of ERNI.

2 Domestic alternative manufacturer selection: Find domestic connector brands that have comparable or close specifications in terms of structure, pin, welding form, insertion and extraction times, and signal performance (such as 10 Gb/s, 25 Gb/s), and reliability.

3. Prototype verification stage: use domestic connectors to make prototypes or small batches, and test the insertion and extraction life, signal integrity, environmental adaptability (such as temperature, vibration) and compatibility.

Step-by-step introduction and risk control: Initially, a "combined use of imports and domestic products" approach can be adopted, with critical interfaces still using ERNI, and other interfaces prioritizing domestic products. Consider a full replacement after the domestic products have been verified and matured.

Ensure that domestic manufacturers have stable production capacity, quality control, after-sales service, and mass delivery capabilities, which is particularly important for project progress and delivery time.

Through this path, the "pilot production of domestically produced connectors" in the project has transformed from an adventure into a controllable process.

In the critical component link of connectors, using international brands like ERNI means that technology and reliability are relatively guaranteed; while "national substitution" represents the future trend of cost optimization, supply chain localization, and flexible customization. For the project team, the most secure approach is "phased implementation, verification, and expansion"—starting with low-risk interfaces and gradually advancing to key modules. As long as technical comparison, prototype verification, and supply chain layout are well done, national substitution is indeed a direction worth trying and promoting.

If you are interested in the domestic substitute products of ERNI brand connectors or have procurement needs, or if you have production or sales channels for these domestic substitute products of ERNI brand connectors and wish to engage in in-depth cooperation or communication, please contact us through the following methods:

Manager Zhang (18665383950, WeChat number same)We look forward to working together with more industry partners!