Today, with the rapid development of artificial intelligence (AI), every link from server-side computing platforms to edge inference devices and to the neural network acceleration modules of smart terminals relies on high-speed, high-density, and highly reliable connectors. Today, we take the internationally renowned brand Murata as a starting point to analyze the technical advantages of its connectors in the AI industry, while also discussing the potential and challenges of domestically produced connectors in this field.

One, Technical Characteristics and Advantages of Murata Connectors1. Brand Profile: Murata is a Japanese manufacturer of electronic components, covering a wide range of products including ceramic capacitors, communication modules,射频 components, connectors, and more.

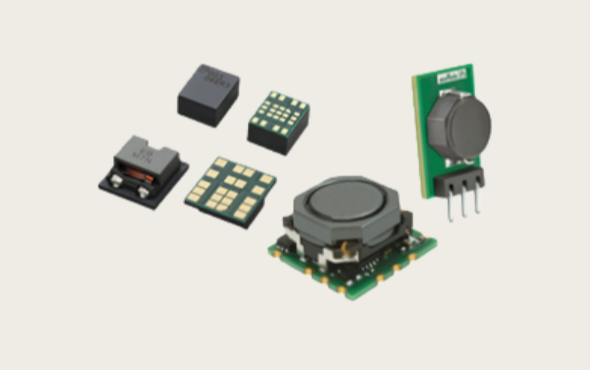

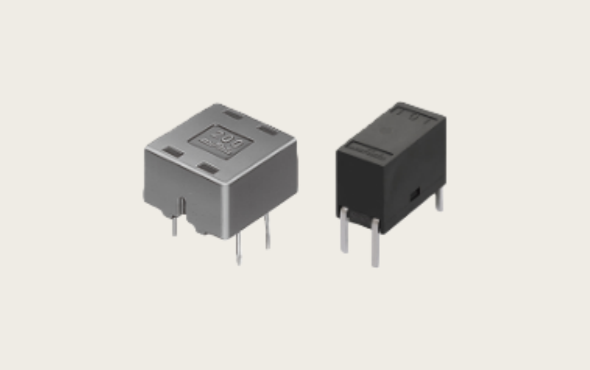

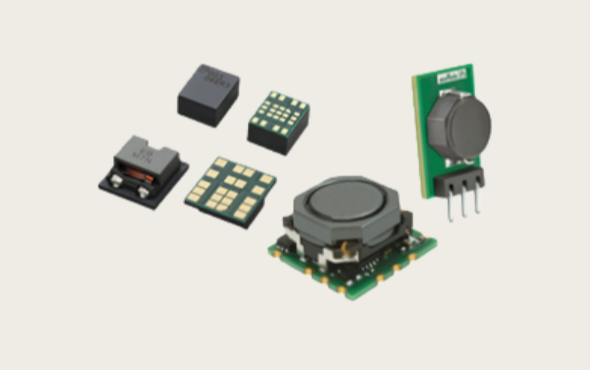

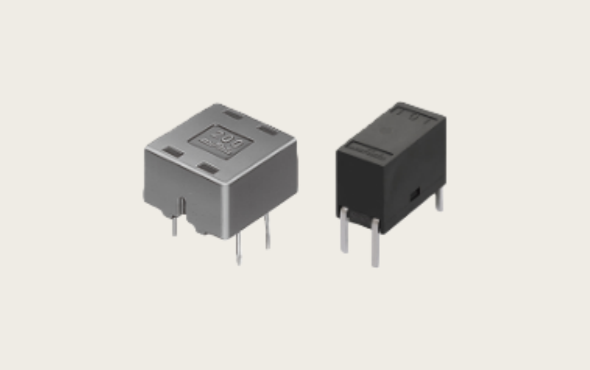

Connector products: Murata's microwave coaxial connectors, board-to-board connectors, etc., are specially designed for high-speed signal transmission, low insertion loss, and stable impedance. The specifications state, "Microwave coaxial connectors transmit radio-frequency signals between circuits and contribute to the development of high-performance communication equipment."

3. High frequency/high speed performance: For example, the model MM8930-2620RJ4 supports 6GHz, 50Ω impedance, and insertion loss of about 0.2dB.

4. Suitable for high-end applications: Murata emphasizes the application scenarios of the connector in "low-loss, board-to-board or RF link."

These characteristics indicate that Murata's connectors have advantages in "signal integrity priority and high-frequency/high-speed data transmission scenarios," which highly aligns with the requirements of connectors in applications such as AI chips, high-speed interconnects, data center networks, and edge devices.

Chapter Two: New Requirements of the AI Industry for ConnectorsIn the AI industry, connectors are no longer just simple power or signal connectors, but are critical links in system performance, reliability, and scalability. The following are several aspects that must be paid attention to:

●High-speed data transmission: Connectors are required to support ultra-high-speed links, low insertion loss, and high bandwidth between high-speed computing modules such as AI chips, GPUs, and FPGAs.

● High-density interconnection and modularity: AI systems are increasingly emphasizing modularity and scalability, and connectors must support multi-channel, high-density, and board-to-board interconnections.

Connector signal integrity and electromagnetic compatibility (EMC): In high-frequency and high-speed environments, the impedance matching, shielding, and anti-crosstalk characteristics of the connectors are particularly important.

Reliability and thermal management: AI devices have high power and strong thermal dissipation requirements, and the connectors need to withstand thermal cycles, vibration, and long-term operating environments.

●Domestic demand and supply chain guarantee: Against the backdrop of the rapid development of the domestic AI industry, the localization of connectors has become an important requirement for supply chain security, cost control, and response speed.

Therefore, the performance of connectors directly affects the stability, performance, and manufacturing cost of AI systems.

Section 3: The Potential and Trends of Domestic Connectors in the AI IndustryWe can see the following potential and opportunities by combining the technical model provided by Murata with the current development status of domestic connector manufacturers:

Breakthrough in high-frequency interconnection: Murata's connectors support GHz-level frequencies. If domestic manufacturers can achieve breakthroughs in high-bandwidth and high-density connectors, they can enter the interconnection link of AI computing platforms.

Highlight localization of supply and customized services: AI chips and modular system updates are fast, and customers expect quick responses and flexible customization. Domestic connectors are tailored to local conditions, have quick response times, and have obvious cost advantages: an entry point.

There is considerable room for improvement in materials, processes, and reliability: although international giants have leading technology, domestic manufacturers have advantages in material localization (such as high-temperature-resistant plastics, gold-plated terminals), automated assembly, and cost control.

Cost and scale advantages are significant: the mass production of AI equipment is rapidly expanding, and as a general but high-performance component, the production cost and supply chain control of connectors are particularly important. Domestication can bring cost advantages and reduce dependence on imports.

5. Strongly driven by policy and market: The state supports the semiconductor, AI, and intelligent manufacturing industries with great strength. As a key electronic component, the direction of domestic substitution for connectors has been put on the agenda.

Therefore, the entry of domestic connectors into the AI industry is not a distant vision but an accelerating trend. If it can match the technical parameters of brands like Murata, and achieve breakthroughs in high speed, high density, and reliability, it will have a strong market competitiveness.

Four, view the domestic substitution strategy from the perspective of Murata's technical advantagesBased on Murata's technical characteristics, we can formulate the following entry strategy for domestic connectors:

●Benchmark Parameters: The domestic connector development needs to at least reach similar bandwidth/impedance characteristics based on Murata's high-frequency connector specifications (such as 50Ω, 6GHz, low insertion loss).

●Modular Compatibility: Design connectors with compatibility in mind for AI modules, GPU cards, accelerator cards, and board-to-board interconnections, to shorten the customer modification cycle.

●Local Service + Fast Delivery: Satisfy AI customers' fast iteration needs through localized production, quick sample response, and customized support.

Cost and quality go hand in hand: maintain stable quality under controllable costs and create a cost-performance advantage.

●Strengthen reliability verification: Establish a reliability system in thermal cycles, vibration, and high-frequency insertion and extraction to enhance customer trust.

Through these strategies, domestically produced connectors are expected to gradually replace them in fields such as AI device interconnection, acceleration modules, and data center servers.

The connector industry's requirements in the AI field far exceed those in traditional consumer electronics. Its characteristics of high speed, high density, reliability, and modularity make the connector a key link in the technological chain. Murata, as an international benchmark for connector technology, has advantages in high-frequency interconnection and high-reliability design that are worth referencing. At the same time, domestic connector manufacturers have natural advantages in terms of material localization, cost control, rapid response, and controllability of the supply chain, and have great potential to open up the market in the AI industry. In the coming years, the domestic connector industry will see explosive growth in the interconnection field of AI modules and systems.

If you are interested in domestic alternatives to Murata brand connectors or have procurement needs, or if you have production or sales channels for this brand of connector alternatives and wish to engage in in-depth cooperation or communication, please contact us through the following methods:

Manager Zhang (18665383950, same WeChat number)We look forward to joining hands with more industry partners to create a new era of AI interconnection!