Under the background of China's promotion of the "Science and Technology Powerhouse" strategy and the construction of high-end manufacturing strong chains and supply chains, as a key component for equipment interconnection, the domestic level of electronic connectors, technical breakthroughs, and industrial support capabilities have attracted much attention. This article takes the internationally renowned connector brand Sullins as a starting point to discuss whether domestic "domestic connectors" have the support of national key laboratories and the significance of this support for the domestic connector industry.

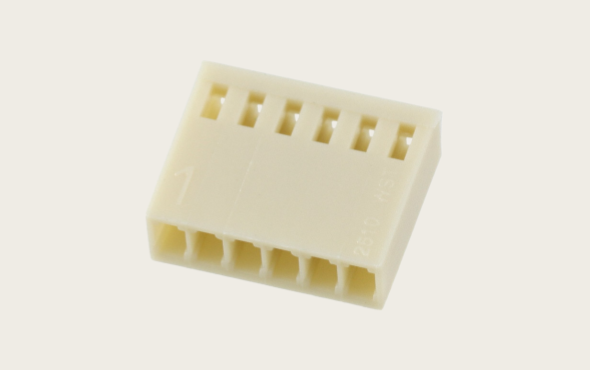

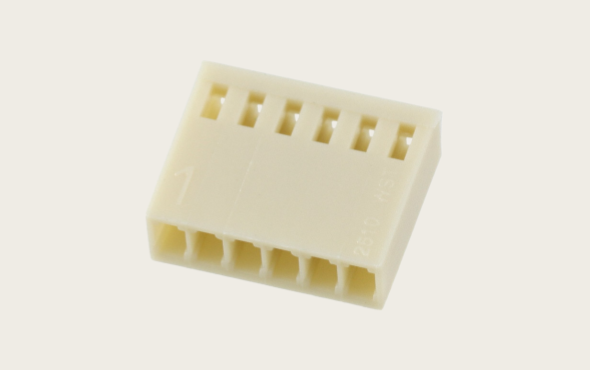

Sullins brand introduction and technical characteristics●Since its establishment in 1971, Sullins has been focusing on board-to-board, card-edge, and high-density, high-temperature connector solutions.

● Its products are widely used in fields such as aerospace, communication, semiconductor, and testing equipment, which have extremely high requirements for connector reliability.

Sullins emphasizes the advantages of "standard parts never going out of production," high quality, and fast delivery (average delivery time within 5 working days).

The brand provides modules such as "Technical Center", "Material Specification", and "Test Reports" in technical documents, indicating that it has a relatively systematic system in terms of reliability, manufacturing process, and material technology.

It can be concluded that Sullins' technical system, product positioning, and service capabilities are relatively mature. When domestically seeking to replace "domestic connectors," it can be regarded as a technical standard and supply chain benchmark.

Discussion on the Relationship between Domestic Connectors and National Key LaboratoryWhat is a national key laboratory?

China establishes "National Key Laboratories" or "National Laboratories" through channels such as the Ministry of Education, the Ministry of Industry and Information Technology, and the Ministry of Science and Technology, as scientific research platforms for technology攻关, high-end technology research, and industrialization foundation. The related list includes research platforms such as the "Connection" aspect, which is supported by the Harbin Institute of Technology's Advanced Welding and Joining National Key Laboratory.

For example, the name of the laboratory itself contains "connection," suggesting that its research scope includes welding and connection technology.

Is the connector named or covered directly by the National Key Laboratory?

At present, no national key laboratory specifically named as "Connector" has been found in public information. However, there are research platforms or key laboratories that conduct research on related technologies such as "connection", "electrical connector", "micro-kinetic wear", and "insertion and extraction durability". For example:

The research article on the micro-arc oxidation of connector contact pieces proposes "Ultrasonic identification and performance degradation model of micro-arc oxidation in electrical connectors."

In the deep-sea industrial field, research institutions have successfully developed a domestically produced "underwater wet insertion and extraction connector," marking a breakthrough in the localization of key technologies for connectors.

The research platform supported by the "Advanced Connection Technology Team" is the "Shanghai Key Laboratory of Digital Manufacturing for Complex Thin Plate Structures" and other provincial key laboratories, which are not national-level but conduct research on technologies related to connections and connectors.

Therefore, it can be said that: although there is no public information indicating that there is a national key laboratory specifically named in the "connector" field, the core technologies of connectors such as "connection", "welding", "plugging and unplugging", "micro-kinetic wear", and "high-speed interconnection" are indeed undertaking research tasks by relevant platforms in national key laboratories or national key laboratories. This also means that the domestic connector industry has an actual foundation supported by scientific research platforms.

The significance of the domestic connector industry

●The existence of research platforms and laboratories provides the possibility of technical breakthroughs and standard formulation for domestic connectors. For example, research in high-frequency plug-in life, temperature resistance, reliability, and micro-kinetic wear.

If a specialized national key laboratory for "Connector" or "Micro-interconnection Device" is established in the future, it will further enhance the technical level, certification capabilities, and industrial ecosystem of domestically produced connectors.

● Compared with the technical systems of international brands like Sullins, the domestic connector industry can form a "specification-test-certification-mass production" chain through scientific research platforms, thereby narrowing the gap.

When the domestication of connectors is supported by laboratories, reliability research mechanisms, and standard alignment mechanisms, its trustworthiness will be higher from the user's perspective.

Suggested next steps for the domestic connector industry

Strengthen the connection of scientific research platforms: it is recommended that domestic connector enterprises actively cooperate with existing national or provincial key laboratories such as "Welding and Connection", "Advanced Connection", and "Micro-interconnection", and strive for special topics or joint construction.

Establish a technical standard closed loop: Take brands such as Sullins as benchmarks, formulate life span, insertion and extraction times, environmental adaptability, and reliability indicators for domestic connectors, and rely on laboratory verification.

●Complement certification and testing capabilities: Establish a dedicated connector testing platform, accelerate aging tests, vibration/temperature cycling tests, supported by a scientific research platform.

Promote industrial chain collaboration: Connectors are not isolated products; they also involve molds, metal stamping, plastic injection, contact plating, and assembly processes. It is recommended to collaborate with the upstream and downstream of the industrial chain through scientific research platforms.

Promote the achievements of domestic technology: When domestic connectors have a laboratory background, scientific research support, and reliability data, they can enhance their recognition through independent stations, brand promotion, industry exhibitions, and other means.

Although there is no national key laboratory specifically named "connector" at present, national key laboratories or national laboratories have already made research and layout in key areas of connector technology such as "connection", "interconnection technology", "insertion and removal durability", and "micro-motion wear". This means that the domestic connector industry has already possessed scientific research basis and technical support. For enterprises hoping to achieve domestic substitution for international brands (such as Sullins), utilizing scientific research platforms, standardized construction, and reliability verification will be an important path to enhance competitiveness.

If you are interested in the domestic substitute products of Sullins brand connectors or have procurement needs, or if you have production or sales channels for these brand connector domestic substitutes and wish to engage in in-depth cooperation or communication, please contact via the following contact information:

Manager Zhang (186 6538 3950, same WeChat number)Contact us, we look forward to joining hands with more industry partners to move forward together.