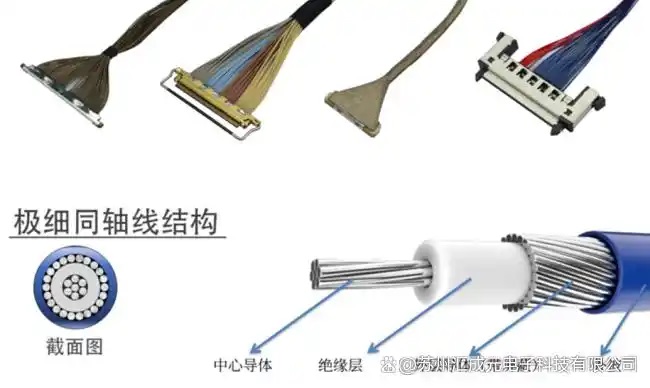

In fields such as drones, security monitoring, liquid crystal displays, tablet computers, ultra-thin laptops, and medical equipment, extremely fine coaxial cables (Micro Coaxial Cable) have become an important solution for achieving high-speed, high-density signal transmission within miniaturized devices. As data transmission rates continue to rise, people are increasingly concerned about how this cable achieves stable transmission and ensures signal integrity. Below, we will systematically analyze its working principle and key technologies.

How does an extremely thin coaxial cable bundle transmit signals?

A super-thin coaxial cable bundle is a compact cable specifically designed for high-frequency and high-speed signals, widely used in various thin and space-limited electronic devices. Its core advantage comes from the high-efficiency electromagnetic control ability provided by the "coaxial structure".

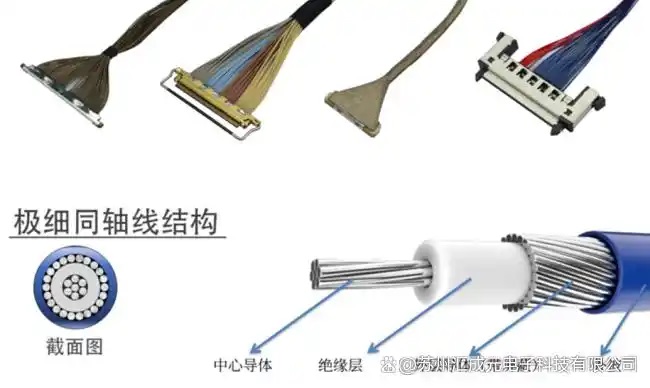

The basic process of signal transmission is as follows:

Center Conductor

As the main signal path, it is responsible for carrying high-speed digital or analog signals.

Insulation layer

Isolate the central conductor from the outer shielding layer to prevent signal leakage and suppress interference conduction.

Shielding layer

Consisting of metal foil and metal woven mesh, it effectively blocks external EMI and prevents crosstalk between adjacent cables.

Outer sheath

Used to protect wire structures, enhance flexibility and durability, and adapt to the internal repeated bending environment of equipment.

Relying on this "conductor-insulator-shielding-sheath" coaxial design, signals can be transmitted at high speeds within the central conductor, while the shielding structure ensures that external noise does not interfere with the integrity of the data, achieving stable high-speed transmission.

Why is signal quality the core of Micro Coaxial Cable?

In high-speed, high-density application environments, factors such as signal attenuation, crosstalk, impedance discontinuity, and reflection will seriously affect data reliability. Moreover, the internal wiring space of ultra-thin devices is limited, making them more susceptible to interference from other components. Therefore, Micro Coaxial Cable must have excellent shielding performance, impedance stability, and manufacturing accuracy to ensure high-speed transmission quality.

How to ensure signal quality for Micro Coaxial Cable?

Multi-layer shielding structure design

A common structure employs a multi-layer shielding combination of silver-plated conductors, high dielectric insulation, metal woven mesh, and metal foil.

Among

The higher the weaving density, the stronger the shielding effect.

Effectively block external EMI interference and ensure stable high-frequency signals.

High-precision concentricity control

Strictly control the concentricity of the conductor and insulation layer during the manufacturing process to maintain consistent overall impedance and avoid signal reflection caused by local impedance jumps.

Accurate impedance matching

Common impedance values are 50Ω/75Ω.

Through strict control of structural dimensions and material ratios, the cable can maintain the standard impedance range, thereby reducing return loss (Return Loss).

Low-loss insulating material

Insulation is usually selected from high-frequency materials such as FEP, ETFE, or PTFE, as they have low dielectric loss and can significantly reduce signal attenuation.

Precision termination process

Micro Coaxial Cable often adopts laser welding, hot pressing welding, or precision connector technology during termination to ensure consistent welding points and stable contact, thus enhancing signal continuity from the source.

Micro coaxial cable can maintain excellent transmission performance in high-speed, high-frequency, and miniaturized applications, which is inseparable from the combined efforts of multi-layer shielding structure, high-precision manufacturing capabilities, low-loss materials, and professional termination technology. With the development of drones, high-definition monitoring, 8K display, and portable medical equipment, the performance requirements for extremely thin coaxial cables will continue to increase, and their application scope will also continuously expand to more complex electronic systems.

We have been focusing on the design and customization of high-speed cable harnesses and ultra-thin coaxial cable harnesses for a long time, committed to providing stable and reliable high-speed interconnection solutions. If you have any related needs or want to learn more, please contact: Manager Zhang.

18913228573 (WeChat number).