Today's smart terminals are becoming thinner and lighter, but their functions are becoming more powerful. From smartphones, tablets to wearable devices, drones, security surveillance, and medical imaging systems, the internal cables of these devices are facing higher requirements. Among them, ultra-fine coaxial cables (Micro Coaxial Cable) are becoming the core choice in the consumer electronics and medical electronics fields due to their advantages in high-density wiring, high-speed signal transmission, and ultra-thin, ultra-flexible structures. In fact, a stable performance ultra-fine coaxial cable bundle has much to learn about its material configuration. Today, we will delve into the key components and material considerations of micro coaxial cable from the perspective of materials.

What is a micro coaxial cable束?

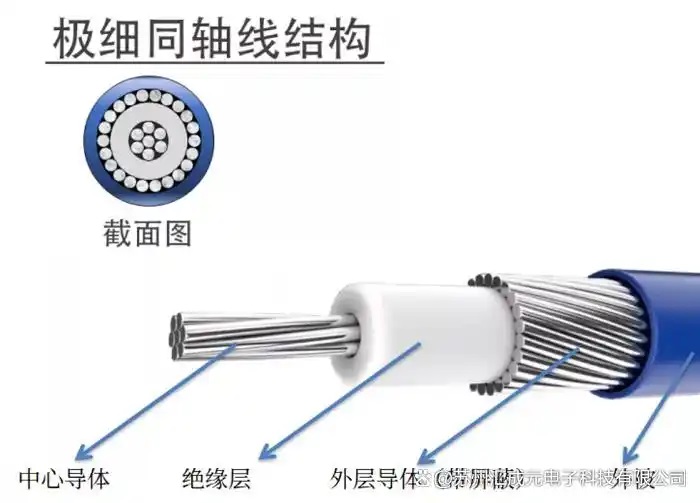

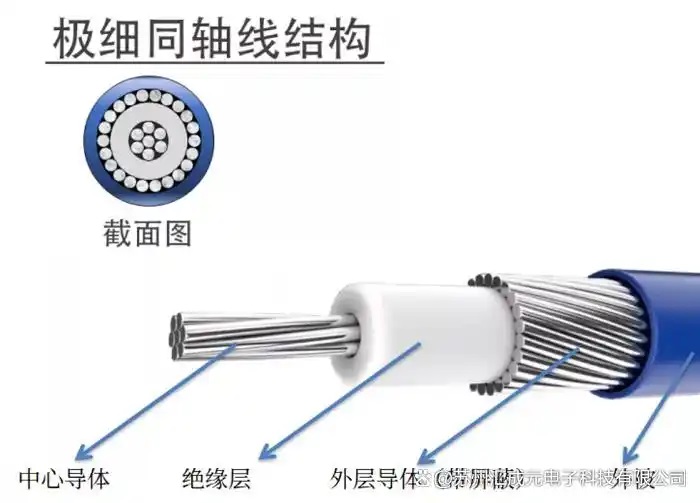

Before discussing the material, let's first understand its structure.

The ultra-fine coaxial cable is usually composed of four layers: inner conductor—insulation—braided shield—jacket. Each layer plays a critical role, and the selection of materials is very strict and demanding.

Second, common materials and considerations for ultra-fine coaxial cables

Conductor: responsible for the "high-speed channel" of signals

Common materials: silver-plated copper wire, bare copper, tin-plated copper

Material requirements:

Silver-plated copper has excellent high-frequency transmission performance and is the first choice for high-speed data scenarios such as mobile phone camera module lines and display FPC transition lines.

Copper has good conductivity but poor antioxidant properties, and its performance is prone to decline over a long period of use.

Tin-plated copper has excellent corrosion resistance and welding performance, suitable for conditions requiring frequent bending or multiple welding.

Insulation layer: Ensuring the purity and stability of the signal

Common materials: FEP, PFA, PE

Material selection is meticulous:

• FEP and PFA have excellent high-temperature resistance, corrosion resistance, and dielectric properties, and are commonly used in medical imaging, high-end industrial equipment, and aerospace fields.

• The PE cost is lower, suitable for general consumer electronic devices, and has a better cost-performance ratio in scenarios with low temperature resistance requirements.

Weaving a shielding layer: a key shield against electromagnetic interference

Common materials: silver-plated copper wire, tin-plated copper wire, bare copper wire

Material attention:

The higher the weaving density, the stronger the shielding performance, which can effectively weaken external electromagnetic interference.

Silver-plated copper wire not only has excellent shielding effect but also has excellent corrosion resistance, which is commonly used as a shielding material in high-end equipment.

Outer sheath: the first line of defense for the internal structure

Common materials: TPU, PVC, FEP

Material selection is meticulous:

TPU is flexible, wear-resistant, and has a good feel, and is commonly used in wearable devices or applications with high requirements for bending life.

• The FEP has characteristics of high temperature resistance, anti-chemical corrosion, etc., and is suitable for complex working conditions and medical scenarios.

PVC is cost-effective and easy to process, but it has relatively poor environmental protection and durability, and has gradually exited the high-end market.

Why is material selection so important?

Extremely fine coaxial cables are commonly used in high-speed, high-precision, and miniaturized equipment, where material requirements are naturally very strict. Inappropriate material can lead to:

Signal attenuation, unstable picture quality or data transmission.

Poor bending resistance, leading to shortened cable life or断裂.

Filtering performance is insufficient, causing crosstalk, affecting the overall performance of the whole machine.

Poor heat resistance, easily aged or cracked during welding.

Therefore, a high-quality ultra-fine coaxial cable束 must integrate all three aspects: structural design, material selection, and process control.

Each layer of the ultra-fine coaxial cable is critical to its performance. The conductor must ensure high-speed transmission, the insulating layer must be stable and reliable, the shielding layer must be effective against interference, and the outer sheath must be wear-resistant and temperature-resistant. Only by reasonably selecting materials based on actual applications can the Micro Coaxial Cable fully exert its performance advantages.

We have been focusing on the design and customization of high-speed cable harnesses and ultra-thin coaxial cable harnesses for a long time, committed to providing stable and reliable high-speed interconnection solutions. If you have any related needs or would like to learn more, please contact: Manager Zhang.

18913228573 (WeChat same number).