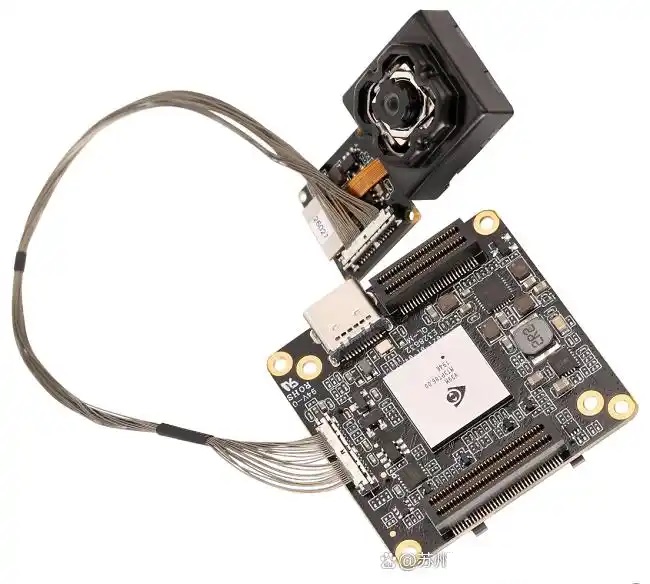

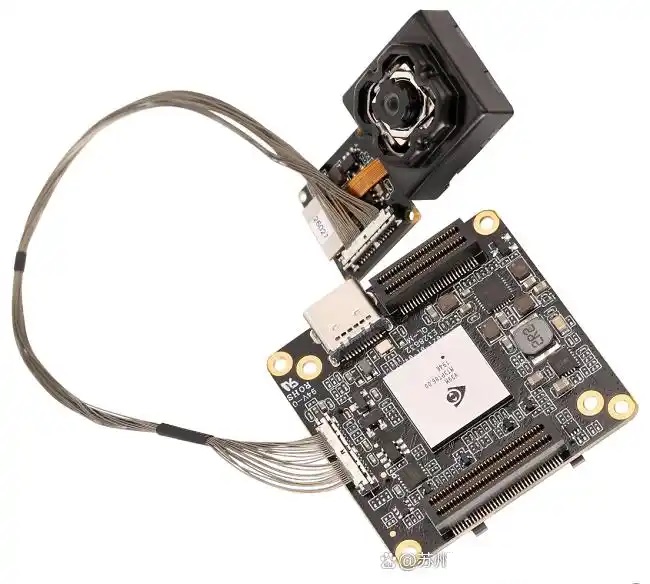

In modern electronic devices, the speed and stability of signal transmission often determine the upper limit of the whole machine's performance. Whether it is a smartphone camera, a high-definition display screen, or medical imaging equipment, and drone transmission modules, ultra-fine coaxial cables (Micro Coaxial Cable) are quietly bearing the heavy responsibility of high-speed signal transmission. However, many people only pay attention to its wire diameter, bend performance, or shielding effect, but rarely notice a key parameter - signal delay (Signal Delay). Do not underestimate the few nanoseconds difference, as it can sometimes affect the synchronization and imaging quality of the system.

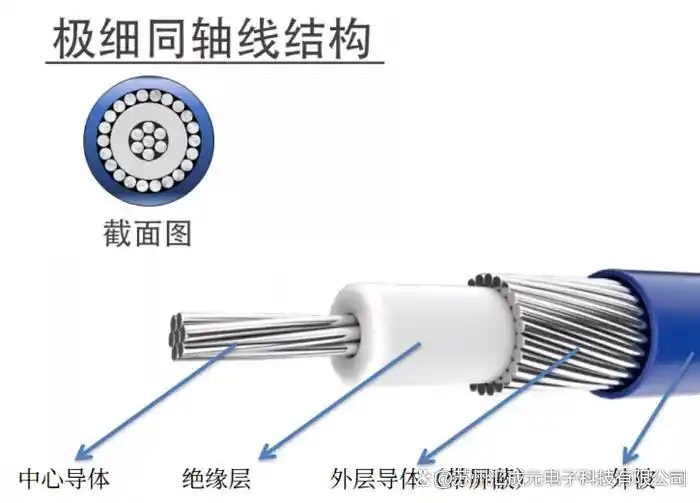

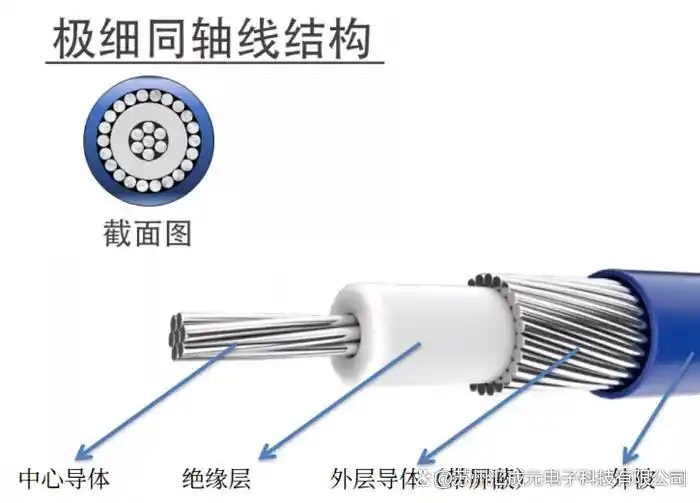

What is ultra-fine coaxial cable?

So-called ultra-fine coaxial cables are those super-fine coaxial transmission lines commonly used in mobile phone camera modules, notebook cameras, and medical equipment.

Its diameter is generally between 0.2mm and 1mm, thin enough to be almost as fine as a hair strand.

From the structural point of view, it is actually a mini version of a coaxial cable.

• Central conductor - thin copper wire, used for transmitting signals;

Insulating layer—the insulating material that wraps around the conductor;

Screening layer - metal mesh or foil, used to prevent electromagnetic interference.

Outer sheath—the outer protective skin, providing mechanical strength and appearance protection.

How to calculate signal delay?

In fact, the calculation is simple, remember a core principle: the speed of signal propagation depends on the dielectric constant of the insulating material. Different materials can make the signal propagate faster or slower. Common insulating materials include PE, FEP, PTFE, etc.

The signal propagation speed of these materials is usually about 66% to 70% of the speed of light.

Experience data as follows:

• PE Material: Approximately 5 ns/m

PTFE material: about 4.8 ns/m

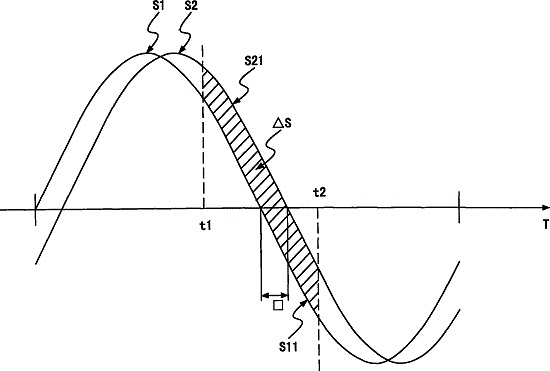

Why should we pay attention to signal delay?

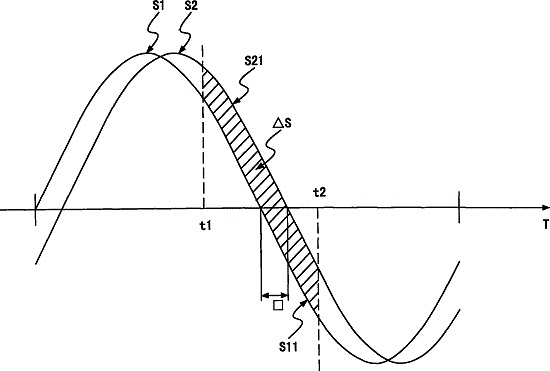

In a normal circuit, nanosecond-level delays seem unimportant, but in high-speed signal systems, they are crucial.

For example, in camera module, high-definition display screen, medical instruments, and drone transmission systems, if the signal delay is inconsistent or too large, it may lead to:

Signal timing disorder

Data conflict or interference

Image tremble, transmission error.

Therefore, in high-speed design, engineers will calculate the delay values at the stage of selecting the routing, ensuring signal synchronization and system stability.

When selecting ultra-thin coaxial cables, it is important to pay attention to not only the wire diameter, bend performance, shielding layer structure, and price, but also the signal delay. By reasonably choosing the insulation material and cable length based on the system speed requirements and material properties, you can ensure more accurate, stable, and reliable transmission of the equipment.

We have long been focused on the design and customization of high-speed cable harnesses and ultra-thin coaxial cables, committed to providing stable and reliable high-speed interconnect solutions. If you have any related needs or would like to learn more, please feel free to contact:

Manager Zhang 18913228573 (WeChat same number).