Categorization:Harness Component

In the trend of high-speed signal transmission and the continuous miniaturization of electronic products, ultra-thin coaxial cables (Micro Coaxial Cable) have been widely used in precision fields such as mobile phones, laptops, medical equipment, drones, and automotive electronics due to their high-frequency low-loss, excellent shielding performance, and excellent flexibility. However, in product exports and domestic sales, the three major safety certifications of UL, RoHS, and REACH have become the key links to ensure product safety and compliance. This article will systematically analyze the core requirements of these three types of certifications.

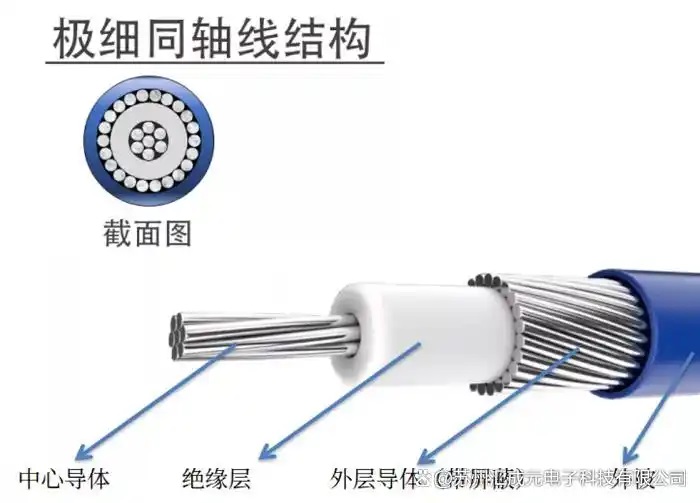

What is a micro coaxial cable (Micro Coaxial Cable)?

Extremely thin coaxial cables, also known as miniature coaxial cables, are a type of high-precision coaxial cables with diameters usually ranging from 0.2mm to 1.13mm. Their typical structure includes the inner conductor, insulation layer, shielding layer, and jacket layer. Compared with traditional coaxial cables, they have the advantages of smaller volume and higher signal transmission efficiency, especially suitable for high-frequency, high-speed signal transmission and micro-space wiring scenarios.

One, UL certification key points

UL (Underwriters Laboratories, an American insurance laboratory) is an internationally recognized safety testing organization. Fine coaxial cables usually need to meet the AWM (Appliance Wiring Material) specifications under the UL758 standard, common models include: UL1571, UL10064, UL1354, UL1357, etc.

Key indicators are as follows:

Rated voltage: generally between 30V and 80V.

Temperature resistance grade: Common specifications are 80℃, 105℃, and 125℃.

Flame retardancy: must pass VW-1 or FT1 flame retardancy test;

• Tolerance range: commonly used AWG46~AWG32, should be selected according to design requirements.

Insulating materials: It is recommended to use environmentally friendly high-temperature-resistant materials such as FEP, PFA, PEEK, ETFE, etc.

RoHS certification key points

RoHS (Restriction of Hazardous Substances) is a directive of the European Union that restricts the use of hazardous substances in electronic and electrical products, focusing on the restriction of 10 hazardous elements including lead, mercury, cadmium, hexavalent chromium, and polybrominated biphenyls (PBB, PBDE).

The RoHS requirements for ultra-fine coaxial cables include:

The insulating layer and sheath must pass the RoHS test.

The metal conductor and electroplating layer shall comply with the requirements of harmful substance limits.

Tin and adhesive must use lead-free or low-lead formulas to ensure overall environmental and regulatory compliance.

Chapter 3 Key Points of REACH Certification

REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) is a regulation established by the European Union for chemicals, with the core focus on controlling the use of Substances of Very High Concern (SVHC).

Key points for REACH compliance of ultra-fine coaxial cables:

All raw materials must have a REACH compliance declaration.

Regularly check for the presence of the latest announced SVHC substances (now exceeding 240 items).

Pay special attention to the chemical composition of insulation, sheath, bonding adhesive, and shielding layer materials.

Four, suggestions for safety regulation certification procedures

To ensure the smooth passage of the extremely fine coaxial cable束 through various certifications, it is recommended that manufacturers follow the following process:

• Material selection stage involves confirming the compliance with relevant regulations;

Submit to a third-party laboratory for safety and environmental testing.

Apply or update the UL file to ensure data validity.

Obtain RoHS and REACH test reports and compliance declarations;

Inspection and record-keeping before shipment for customer or regulatory review.

As the core transmission component in the high-precision electronic field, the safety certification of ultra-fine coaxial cables not only determines whether the product can be smoothly exported but also reflects the quality management and brand reputation of the enterprise. By selecting materials reasonably, conducting strict inspections, and continuously paying attention to the updates of regulations, manufacturers can steadily advance in the international market, achieving dual improvements in product safety and competitiveness.

We have been focusing on the design and customization of high-speed cable harnesses and ultra-fine coaxial cable harnesses for a long time, committed to providing stable and reliable high-speed interconnection solutions to our customers. If you have any related needs or want to learn more, please contact: Manager Zhang.18913228573 (WeChat number).