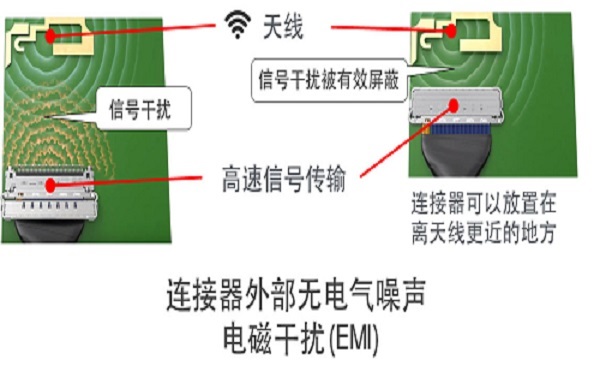

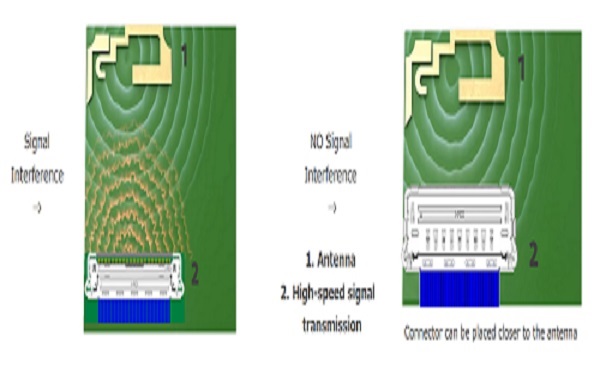

With the continuous development of electronic devices towards high performance, low power consumption, miniaturization, and high integration, the complexity of internal signal transmission has significantly increased. Transmitting power, control signals, and high-speed data signals simultaneously in a limited space has become a basic requirement for modern electronic systems. This multi-signal parallel transmission mode makes electromagnetic interference (EMI) issues more prominent. Particularly in high-speed signal channels, without good shielding and grounding design, electromagnetic radiation not only destroys signal integrity but may also affect the normal operation of internal antennas and sensitive circuits, ultimately leading to reduced system stability or abnormal function.

Electromagnetic noise issues in compact equipment

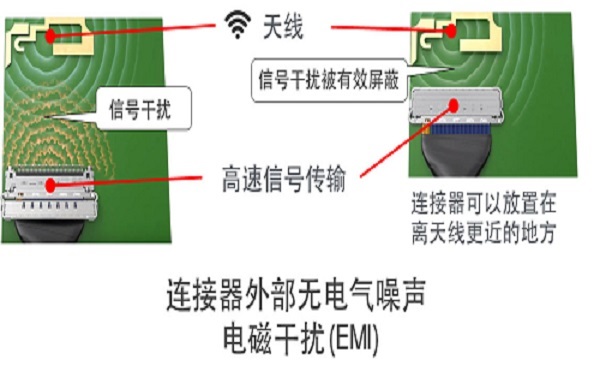

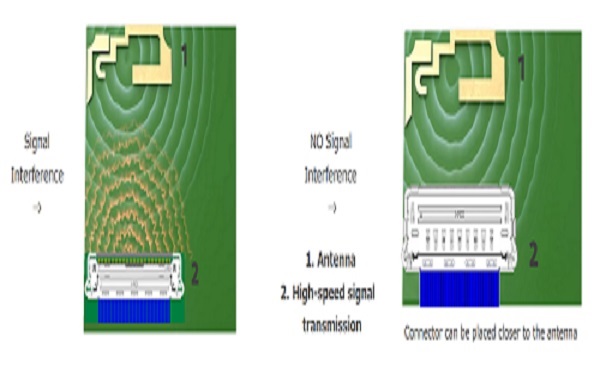

Modern electronic devices such as laptops, tablets, smartphones, and vehicle electronic systems commonly integrate various wireless communication modules (such as Wi-Fi, GPS, LTE, and 5G). These products operate under high-density packaging with extremely close distances between internal components, low working voltages, and limited anti-interference capabilities. The high-speed digital signals and their high-frequency harmonics are prone to become the main sources of electromagnetic radiation. If not effectively controlled, these radiation signals may affect wireless communication modules and sensitive circuits through spatial coupling or conduction paths, leading to signal fluctuations, system mis-triggering, or even component damage.

Part Two: Traditional EMI Suppression Measures and Their Limitations

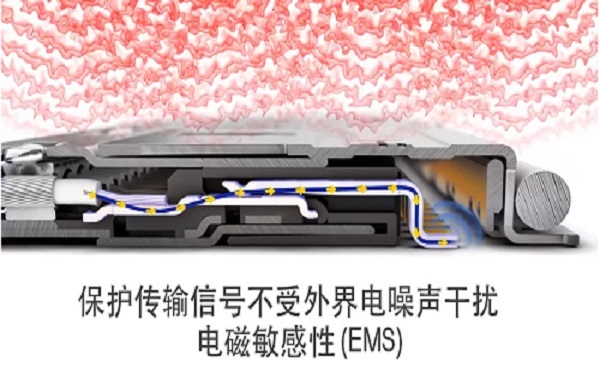

Common EMI countermeasures include: adding filter devices in circuit design, installing metal shielding covers for sensitive components, and optimizing PCB routing and impedance matching. These methods can effectively reduce radiation noise at the circuit board level, but at the positions of cables, connectors, and jumpers, signal lines are often directly exposed, especially at the welding ends and unshielded connectors, which can become the "leakage points" of EMI. Therefore, even if the PCB shielding effect is ideal, the overall electromagnetic compatibility performance of the system may still be limited due to insufficient cable shielding.

The importance of wire harness shielding structure

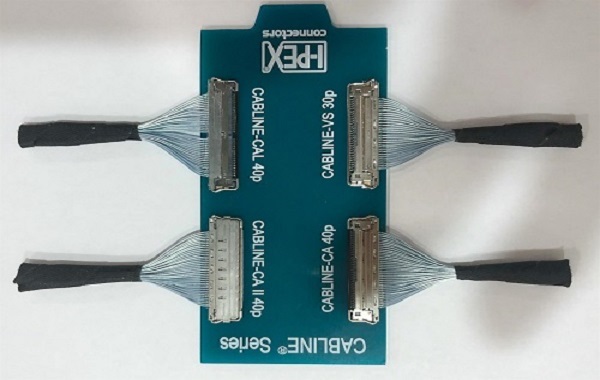

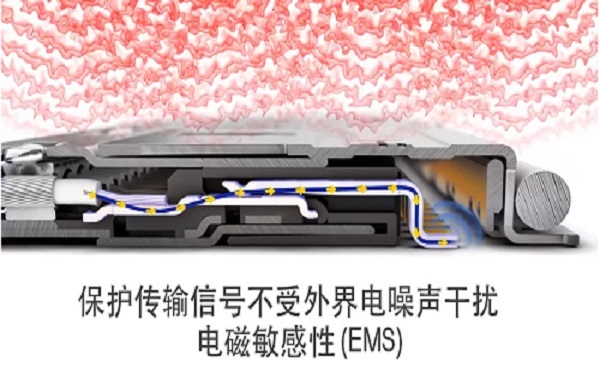

In high-frequency transmission systems, to ensure signal integrity and suppress interference, an increasing number of designs adopt FPC flexible ribbon cables with all-around shielding layers, micro-coaxial cables, and twinaxial cables. Among them, micro-coaxial cables, with their coaxial structure of central conductor and shielding layer, can achieve efficient electromagnetic isolation. The central conductor not only transmits high-speed signals but can also be used for power supply. The outer shielding layer serves as both a current return path and a protective barrier, effectively reducing interference noise in complex electromagnetic environments. This structure exhibits excellent anti-interference performance in industrial automation, robot servo drives, and high-speed data communication systems.

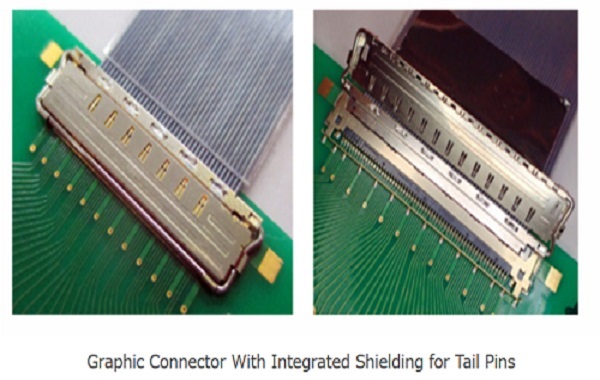

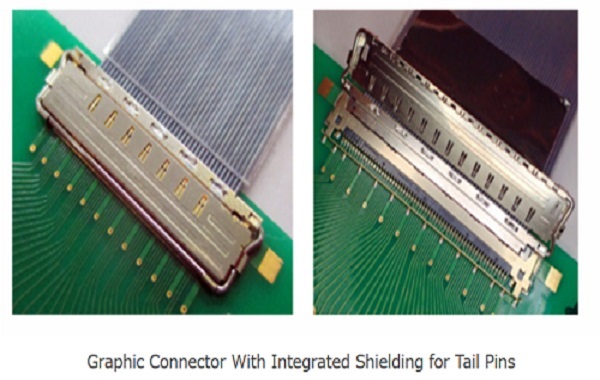

Four, the shielding advantages of high-performance EMC connectors

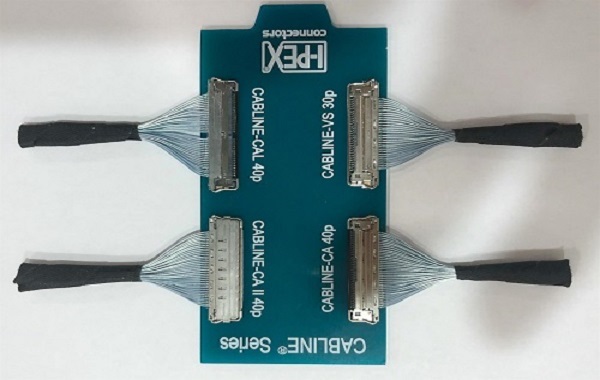

In response to the problem of EMI leakage at the焊接 terminal of traditional connectors, some high-end connector manufacturers have introduced EMC connectors with a full shielding structure. These products adopt a 360°metal shielding design for signal contacts, welding areas, and the housing, which can completely enclose the electromagnetic radiation within the connector, blocking the interference propagation path at the source. This structure is particularly effective in high-frequency, high-density systems and has been widely used in laptops, tablets, smartphones, and communication base station equipment. Especially in high-speed wireless signal environments such as Wi-Fi, GPS, LTE, and 5G, EMC connectors have become a key component for ensuring system performance and signal stability.

With the popularization of high-speed signal interfaces and the continuous compression of device spaces, relying solely on traditional PCB-level EMI protection is no longer able to meet the system-level anti-interference requirements. By synchronously introducing shielding design at the cable, jumper, and connector levels, especially using high-performance EMC connectors with full shielding structures at the welding ends, it is possible to effectively control electromagnetic leakage, enhance system signal integrity and electromagnetic compatibility. This is not only a key means to ensure the stable operation of high-speed communication but also an important trend in the design of future high-density electronic devices.

I am

[Suzhou Hui Cheng Yuan Electronic Technology],Long-term focus on the design and customization of high-speed signal cable harnesses and ultra-fine coaxial cable harnesses, committed to providing stable and reliable high-speed interconnect solutions. For further information or customization of special cable harness solutions, please contact:

Manager Zhang 18913228573 (WeChat same number)。