Categorization:Harness Component

With the rapid development of high-speed and miniaturized electronic devices, the precision and assembly requirements of signal transmission harnesses have significantly increased. Ultra-fine coaxial harnesses and micro-coaxial cable harnesses, with their excellent high-frequency transmission performance and flexibility, have been widely used in high-density connection scenarios such as laptops, tablets, smartphones, camera modules, and vehicle imaging systems. To ensure signal integrity and production consistency, such harnesses must undergo strict pretreatment and assembly processes during manufacturing.

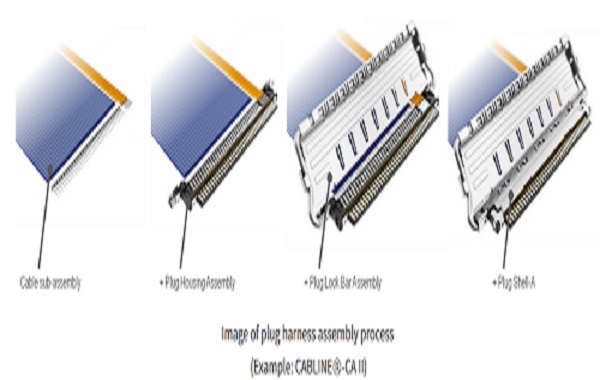

First, the main process of cable assembly is as follows:

The production of extremely fine coaxial cable assemblies and micro coaxial cable harnesses generally includes the following main processes:

1. Despiking and preprocessing

Strip the outer sheath and process the ends of the micro coaxial cable to make "cable sub-assembly" for subsequent plug welding and assembly.

Cable subcomponent assembly and welding

Insert the pre-processed cable sub-component into the plug housing component, and precision weld the center conductor to the signal terminal to ensure a reliable connection.

Install lock buckle component

Install the lock cover or lock part on the plug housing according to the design structure to enhance the connection strength and durability.

Cover the shell and complete the final welding

Cover the plug shell over the cable and connection parts, and weld at the specified location to complete the terminal assembly of the entire harness.

The significance of pretreatment for cable sub-component

Pre-treatment of the micro-coaxial cable before terminal wire welding is an important step to improve assembly efficiency and product consistency. Standardized pre-treatment ensures that each cable has consistent lengths, stripping sizes, exposed shielding layer ranges, and grounding terminal processing. In addition, during the terminal assembly stage, the external conductor of the cable needs to be welded to the metal shell of the connector to form a reliable grounding path, thereby effectively reducing electromagnetic interference (EMI) and ensuring the integrity and stability of high-speed signal transmission.

Three, common types of cable subcomponents

In response to different system design and usage requirements, extremely fine coaxial cable bundles usually support the following types of structures:

Pure micro coaxial cable type

The use of a single type of micro-coaxial cable to manufacture subcomponents allows for the selection of cables with different outer diameters and impedance specifications, making it suitable for high-speed signal pure transmission scenarios.

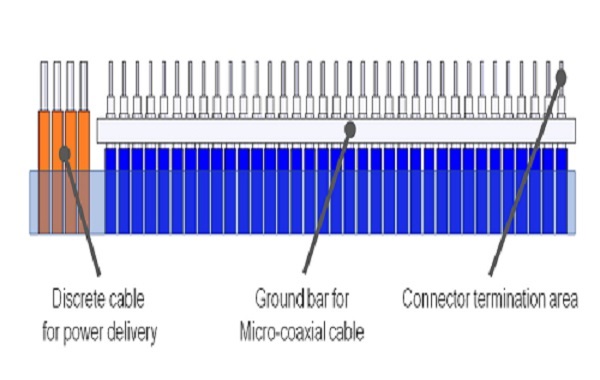

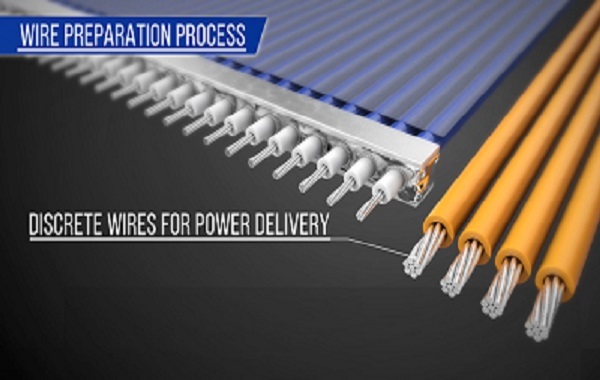

2. Micro coaxial and single wire hybrid type

Combining micro coaxial cables with discrete single wires is commonly used to meet the combined requirements of high-speed signal and power line routing, often found in camera modules, display interfaces, and other composite cables.

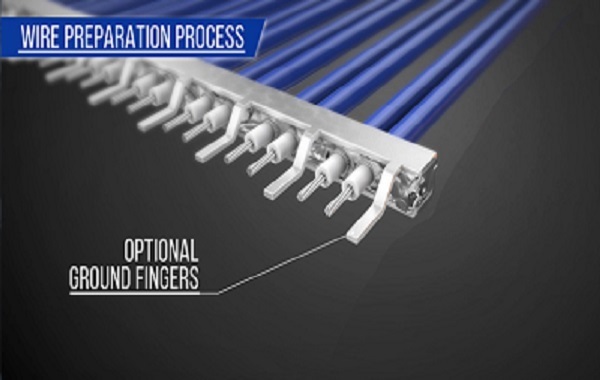

Grounding busbar with grounding terminal

Directly solder the grounding bus bar with ground fingers directly to the plug terminals to achieve the purposes of simplifying cable layout, reducing grounding impedance, improving signal integrity, and enhancing anti-interference performance.

Four, the advantages and applications of harness processing technology

Through standardized cable sub-component preprocessing and precise assembly technology, not only can production yield and assembly efficiency be improved, but the electrical performance and mechanical reliability of cables can also be significantly enhanced. Ultra-thin coaxial cable bundles and micro coaxial cable bundles, with their high density, low loss, and excellent flexibility, have become an important part of the high-speed signal and high-frequency interconnect fields. They continue to play a crucial role in consumer electronics, industrial control, vehicle imaging and communication terminals.

The manufacturing process of ultra-fine coaxial and micro coaxial cable harnesses is a key link for achieving stable high-speed signal transmission and system electromagnetic compatibility performance. Through precise stripping pretreatment, reliable terminal welding, and reasonable shielding grounding design, it can ensure that the harness maintains excellent signal integrity and long-term reliability in high-frequency environments. In the future, with the continuous development of high-speed interfaces and high-density interconnection technologies, the standardization and automation of cable sub-components will become an important trend in the industry.

I am[Suzhou Huichengyuan Electronic Technology]Long-term focus on the design and customization of high-speed signal cable harnesses and ultra-fine coaxial cable harnesses, committed to providing stable and reliable high-speed interconnection solutions. If you have related needs or want to learn more, please contact:Manager Zhang 18913228573 (WeChat same number)。