Categorization:Harness Component

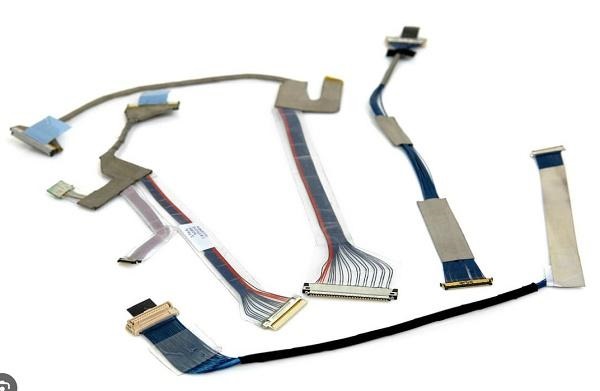

Today, with the continuous growth of high-speed signal transmission requirements, extremely thin coaxial cables (Micro Coaxial Cable) are widely used in precision fields such as medical equipment, industrial cameras, and robot modules, thanks to their small size, high performance, and strong anti-interference ability. Many engineers will raise the same question at the design stage:

How long can this extremely thin wire material be used without breaking after repeated bending?

Key factors affecting bending life

Cable structure

Fine coaxial cables are usually composed of inner conductor, insulating layer, shielding layer, and outer sheath. Their flexibility and fatigue resistance are directly related to the material selection and structural design. For example, high-purity copper or silver-plated conductors have good ductility and are less prone to metal fatigue or breakage during repeated bending.

Bend radius

Extremely thin coaxial cables are flexible, but they are not freely bendable. Industry experience shows that the minimum bending radius is usually 5 to 10 times the diameter of the wire. If used for a long time below this radius, the internal conductor is prone to stress concentration, leading to premature fatigue cracks.

Use environment

Environmental conditions have a significant impact on the bending life. High temperatures, humidity, or exposure to chemicals can accelerate the aging of the sheath and weaken the structural stability. In the medical or industrial fields, reliability tests are often carried out under simulated恶劣 environments to verify the long-term performance of the product.

Actual bending life for reference

The experimental data shows that high-quality ultra-fine coaxial cables can achieve tens of thousands of even more than a hundred thousand bending cycles without breaking when subjected to dynamic bending tests at normal temperature with reasonable bending radii.

The ultimate service life still needs to be comprehensively evaluated based on the actual application environment, installation method, and the test results provided by the manufacturer.

Three, key design points for improving bending life

Optimize routing design: Try to avoid sharp angles or extreme bending paths.

Select high flexibility structural materials: Using cables with flexible insulating layers and woven shielding structures helps to distribute stress.

Increase stress relief structures: Adding sheath transition or guide slot design at critical locations can effectively extend the lifespan of wire harnesses.

The bending life of ultra-fine coaxial cables is not a fixed value, but a dynamic indicator determined by structural design, material selection, installation method, and usage environment. Through scientific design and reasonable wiring strategies, Micro Coaxial Cable can fully meet the long-term stable high-speed signal transmission requirements, providing reliable interconnection guarantees for modern electronic devices.

I amSuzhou Huichengyuan Electronic, Focuses on the design and customization of high-speed cable harnesses and ultra-fine coaxial cable harnesses, committed to providing stable and reliable high-speed interconnection solutions. If you have related needs or wish to learn more, please contact:Manager Zhang 18913228573 (WeChat number)。