Categorization:Harness Component

In modern medical equipment, the role of cables has long gone beyond the basic function of "electrical connection." They are responsible for high-speed signal transmission and also undertake the critical tasks of power supply and system stability. Due to the extremely high requirements for safety, reliability, and traceability in the medical field, medical cables must pass multiple strict international certifications.

The main certification requirements for medical cables

ISO 13485 Quality Management System

This is the most core system certification in the medical device manufacturing industry, ensuring that manufacturers meet the standardized requirements of the medical industry in terms of design, production, assembly, and testing.

UL/CSA safety certification

In the North American market, wire and insulation materials often need to pass UL or CSA certification to prove that they meet safety standards in terms of voltage resistance, flame retardancy, and high-temperature resistance.

RoHS/REACH environmental compliance

Medical equipment must comply with EU and global environmental regulations to ensure that the products do not contain harmful substances such as lead and halogens, in order to protect the health of users and environmental safety.

Biocompatibility and sterilization adaptability

For medical cables that come into direct or indirect contact with the human body, they must pass biological compatibility tests such as ISO 10993, and verify their stability and reliability under environments such as ethylene oxide sterilization, gamma ray sterilization, or high-temperature and high-pressure sterilization.

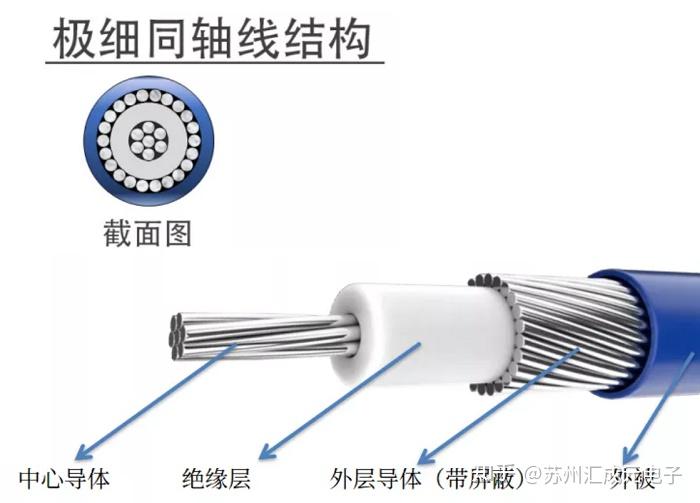

The medical application advantages of ultra-fine coaxial cables (Micro Coaxial Cable)

Extremely fine coaxial cables, due to their tiny outer diameter, high impedance consistency, and excellent flexibility, have been widely used in endoscopes, ultrasonic probes, and minimally invasive surgical equipment and other fields. Their characteristics perfectly meet the core needs of medical equipment:

High bandwidth, low loss

Supports high-speed data signal and high-definition video transmission, ensuring clear images and real-time response.

High flexibility and miniaturized design

Diameter is usually only 0.3mm to 0.5mm, capable of wiring in extremely narrow mechanical structures, and has excellent bend life.

Medical-grade material selection

The product can adopt medical-grade PTFE insulation and FEP sheath, which can cater to high-temperature resistance, chemical corrosion resistance, and compatibility with various sterilization methods.

Of course, having only high-quality cable performance is not enough to enter the medical field. A complete cable assembly must pass the ISO 13485 system certification during the production process and meet the RoHS, REACH, and biocompatibility standards at the material level in order to enter the compliant medical supply chain system.

The certification system for medical cables is not only a safety guarantee but also a testament to product quality. The ultra-thin coaxial cable, with its excellent electrical performance and miniaturization characteristics, has become an ideal high-speed interconnection solution for high-end medical equipment. As long as the materials, design, and system certification are properly matched, it can meet the stringent requirements of the medical industry for reliability and safety.

I am[Suzhou Huichengyuan Electronic], focusing on the design and customization of high-speed signal cables and extremely thin coaxial cables, committed to providing stable and reliable interconnection solutions. If you have related needs or wish to learn more, please contact:Manager Zhang 18913228573 (same as WeChat)。