Categorization:Harness Component

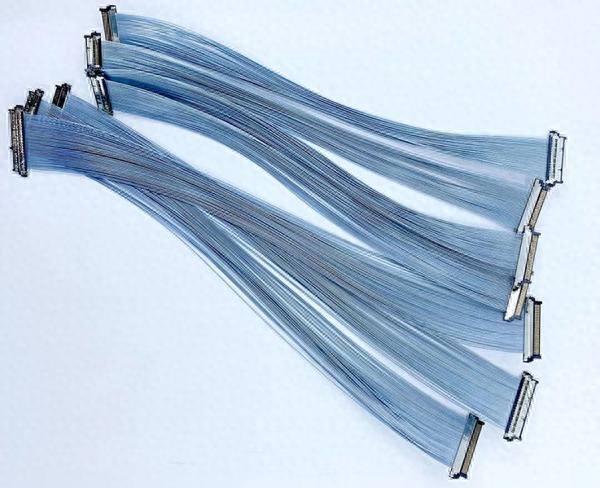

In the era of continuous evolution in high-speed transmission and equipment miniaturization, micro coaxial cable has become an indispensable core connection component in high-end fields such as smartphones, wearable devices, medical electronics, and AR/VR. While achieving high-speed signal transmission, it also needs to consider lightweighting, flexibility, and high-density wiring capabilities. The key to creating a micro coaxial cable with stable performance lies in the scientific selection of materials and the precise control of processes. The following will analyze in depth from both "materials" and "manufacturing processes".

Part 1: Analysis of Common Materials

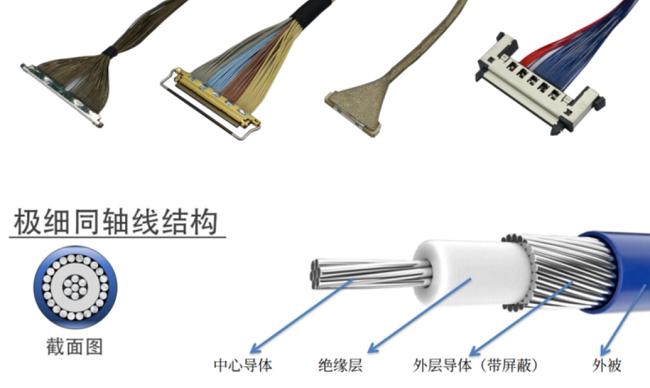

The central conductor: The signal transmission performance of a very thin coaxial cable depends on the conductivity of the conductor material. High-purity copper or silver-plated copper wire is usually used to reduce resistance and minimize high-frequency signal loss. In some high-end applications, a multi-strand ultra-fine copper wire braided structure is selected to further enhance flexibility and reduce signal attenuation caused by bending.

Insulating layer (dielectric): Common insulating materials include polyethylene (PE), polypropylene (PP), perfluoroethylene propylene (FEP), and polytetrafluoroethylene (PTFE). Among them, PTFE is renowned for its excellent high-temperature resistance and dielectric properties, making it the preferred material for high-frequency and precision equipment.

Shielding layer: To suppress electromagnetic interference (EMI), the shielding layer usually adopts a structure of high-density copper wire weaving, aluminum foil wrapping, or silver-plated copper woven mesh. For high-speed transmission occasions that require signal integrity, full coverage woven shielding is particularly critical, which can significantly enhance anti-interference and transmission stability.

The outer sheath: The outer sheath not only provides mechanical protection but also needs to have excellent corrosion resistance and environmental adaptability. Common materials include PVC, FEP, PFA, etc., to ensure the long-term reliability of the cable in complex application environments.

Chapter 2: Key Manufacturing Processes

Precision stripping: The diameter of extremely fine coaxial cables is usually between 0.3mm and 1mm. Traditional mechanical stripping methods are difficult to ensure accuracy, therefore, laser stripping technology is often used, which can accurately remove the insulation layer and protect the delicate conductors from being damaged.

Welding and Terminal Connection: After stripping the wire, the conductor needs to be tin-plated, and then fixed with terminal or connector by means of thermal pressure welding or laser welding to ensure stable impedance and a firm welding point, thereby avoiding signal loss due to poor contact.

Cable assembly: In the assembly stage, multiple processed cables are arranged in order and connected to the corresponding connectors. For high-speed signal transmission applications, a 360° full-shielding structural design is often adopted to minimize external interference as much as possible.

Inspection and Quality Control: After assembly, the wiring harness must undergo a series of tests including insertion loss, return loss, impedance consistency, and more to ensure that each product meets strict transmission standards and reliability requirements.

The performance of extremely thin coaxial cable束 is determined by the perfect combination of high conductivity materials, low dielectric loss insulating media, full shielding structural design, and high precision manufacturing process. The synergistic application of high-quality silver-plated copper conductors, PTFE insulating layer, and laser stripping technology allows it to show extremely low loss and high stability in high-speed signal transmission. The extremely thin coaxial cable束 is not only a connection line, but also a key solution for high-speed and low-interference transmission in high-performance equipment.

I am[Suzhou Huichengyuan Electronic]Long-term focus on the design and customization of high-speed cable harnesses and ultra-fine coaxial cable harnesses, committed to providing customers with high-quality and reliable high-speed interconnection solutions. If you have related needs or want to learn more in depth, welcome to contact:Manager Zhang 18913228573 (WeChat same number)。