Categorization:Harness Component

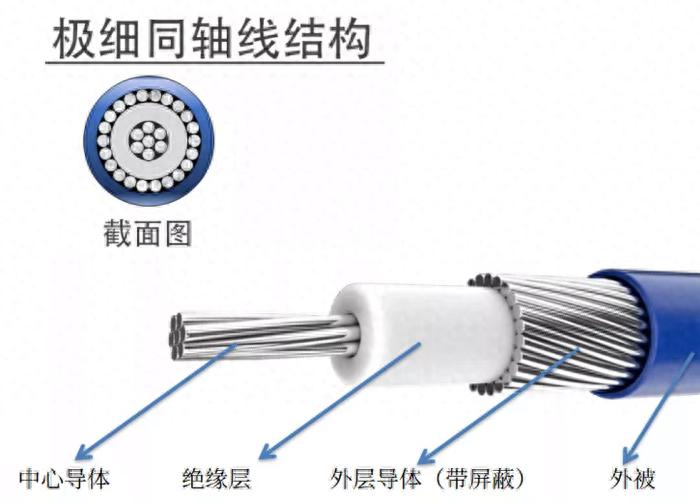

In modern electronic devices, ultra-fine coaxial cables are known as the "invisible hero" of high-frequency and high-speed signal transmission. They have a compact structure and high flexibility, and are widely used in devices with extremely high requirements for signal integrity, such as smartphones, laptops, tablets, medical equipment, and drones. However, in these sophisticated systems, "impedance matching" is a crucial technical point that must be paid close attention to. Many engineers are aware of its importance, but may not fully understand why it is so critical.

Impedance matching directly affects signal integrity

In the process of signal transmission, only when the impedance of the cable, connector, and load is consistent can the signal be transmitted smoothly; if there is a mismatch, part of the signal will be reflected to form standing waves, resulting in energy loss and waveform distortion. For miniature electronic systems, even the slightest distortion can lead to image abnormalities, communication errors, or system instability.

Under high-frequency conditions, problems are more prominent.

Extremely fine coaxial cables are commonly used in high-speed interface scenarios, such as the MIPI channels of cameras and the eDP connections of displays. The higher the frequency, the more sensitive the impedance control becomes. In millimeter wave or high-speed digital signal environments, even a few ohms of deviation may cause significant waveform distortion, speed reduction, and even data errors.

Impedance mismatch will also bring energy consumption and heat issues.

Impedance mismatch not only destroys signal integrity but also causes power reflection. The reflected energy is converted into heat, increasing the internal temperature rise of the system. For devices with compact volume and limited cooling conditions, this additional heat directly affects the life and reliability.

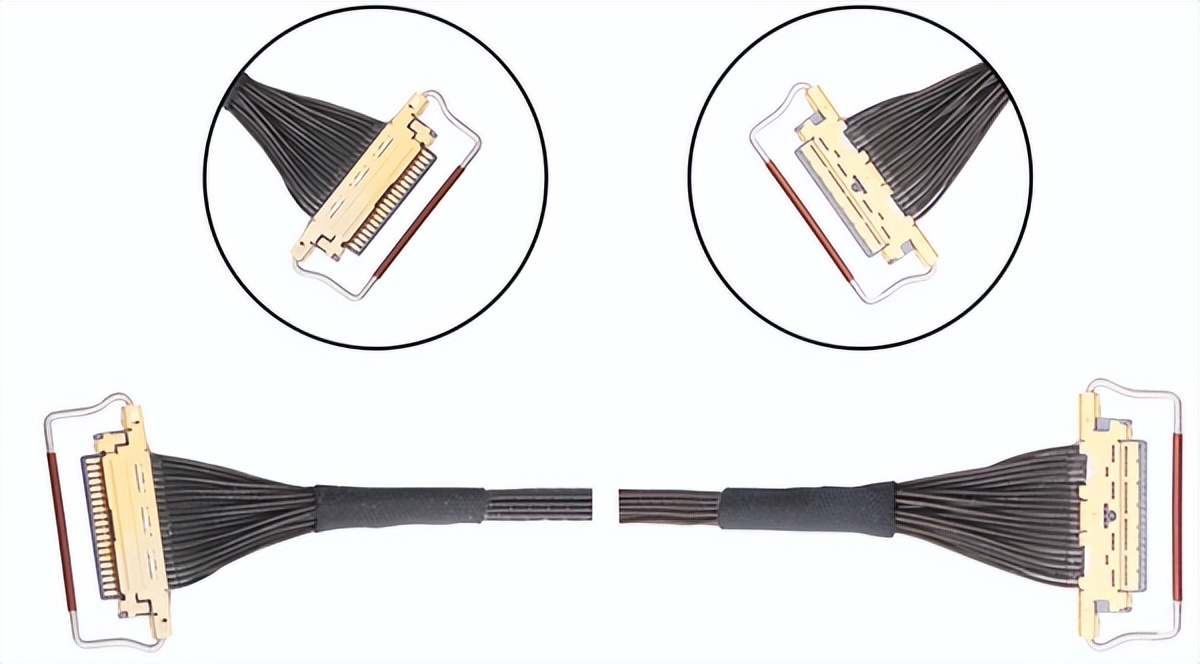

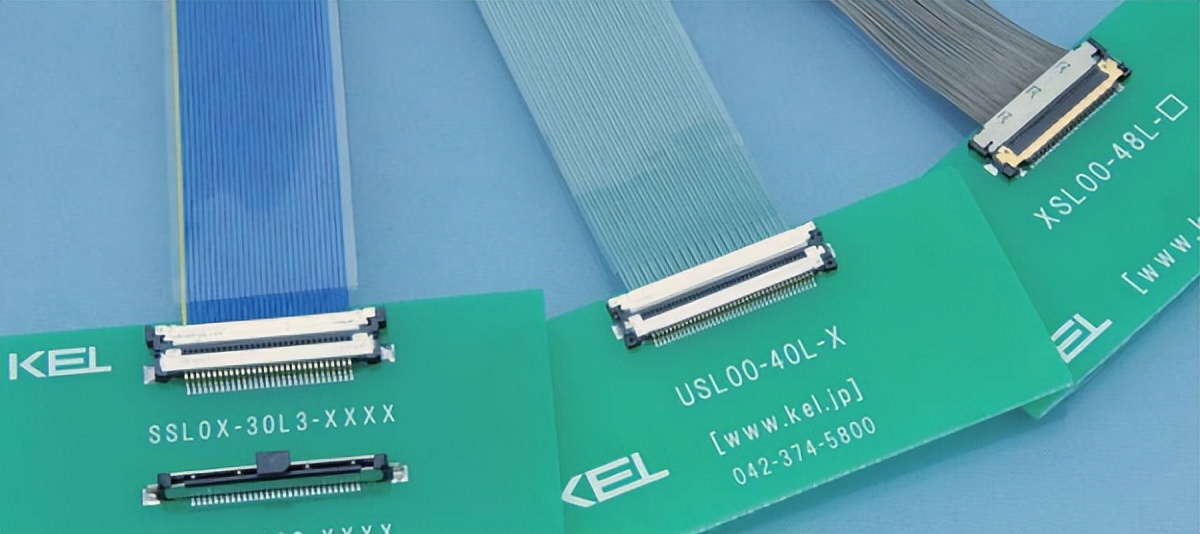

Connectors are equally critical as system design.

Micro-coax cable harnesses are usually paired with miniature connectors such as KEL, Hirose, and I-PEX. Even if the cable harness itself has precise impedance, signal reflections and interference can still be introduced if the connector or PCB routing design does not match. Therefore, impedance matching must be considered from the perspective of the entire signal chain, not just the issue of the cable harness itself.

Choose high precision impedance cable: commonly used standards are 50 Ω or 45 Ω.

Properly match the connector with PCB design: impedance continuity should be controlled during the interface and layout stages.

Conduct simulation verification: uncover potential problems in advance through electromagnetic simulation.

Adjustment network introduction as necessary: impedance fine-tuning and compensation for high-frequency links. For extremely fine coaxial cable bundles, impedance matching is not a "nice to have" additional requirement, but rather a core link to ensure performance and reliability. Only by strictly controlling the impedance from the early stages of design can stability and efficiency be maintained in high-speed signal transmission, allowing the equipment to truly perform as expected.

For extremely fine coaxial cable bundles, impedance matching is not a "nice to have" additional requirement, but rather a core link to ensure performance and reliability. Only by strictly controlling the impedance from the early stages of design can stability and efficiency be maintained in high-speed signal transmission, allowing the equipment to truly perform as expected.

I am[Suzhou Huichengyuan]Long-term focus on the design and customization of high-speed signal cable harnesses and ultra-fine coaxial cable harnesses, committed to providing customers with high-quality high-speed interconnect solutions. If you have any related needs or would like to learn more, please contact:Manager Yin 18913280527 (WeChat number the same)。