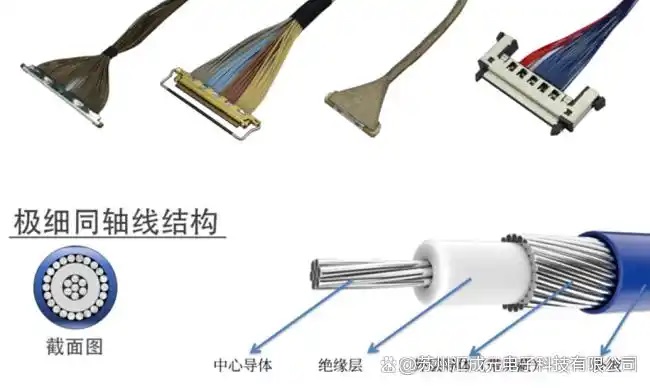

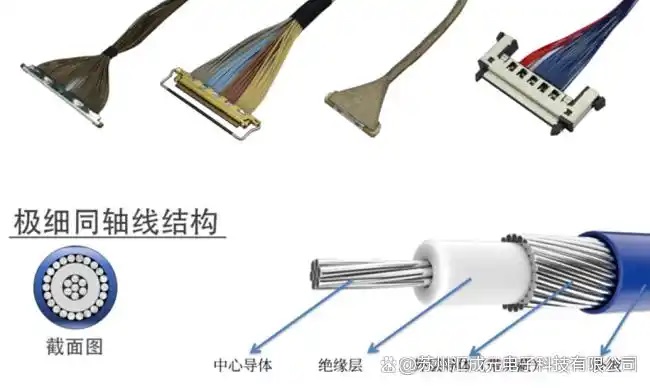

In micro electronic products such as tablet computers, high-definition display modules, camera components, and high-precision medical equipment, extremely fine coaxial cables (Micro Coaxial Cable) are widely used for high-frequency signal transmission due to their ultra-fine, lightweight, high-speed transmission, and strong anti-interference characteristics. The common wire diameter is only 0.3mm~1.2mm, and its internal structure usually consists of a central conductor, insulation layer, woven shielding layer, and outer sheath. The structure is similar to that of a common coaxial cable, but it is finer and softer, suitable for applications in limited spaces.

The common reasons for the heating and scorching of extremely fine coaxial beam cables

In practical applications, if extremely thin coaxial cable bundles encounter heating issues, it may lead to unstable signals, abnormal images, and even damage to devices. The following are several common causes of analysis:

Overcurrent

The rated current of extremely fine coaxial cables is usually only 0.3A~1A. If the working current exceeds the rated value, the resistance heating inside the conductor will significantly increase.

The wire becomes hot and even softens and deforms after long-term operation.

Grounding is poor or contact resistance is too high

When焊点、插头or端子出现虚焊、氧化、松动等情况,会形成接触电阻,引起局部过热。

Performance: A hair at the joint is hot, accompanied by phenomena such as unstable signals or flickering screens.

Improper wire selection

If the wire gauge (AWG) is too small or the material quality is poor (high conductor resistance, sparse shielding), it is more prone to generate heat during long-distance or high-frequency transmission.

High ambient temperature, poor heat dissipation conditions

When used in sealed spaces or high-temperature equipment cavities, heat is not easy to dissipate, and the cables are prone to accumulate heat and increase in temperature.

High-frequency signals cause medium loss

The extremely thin coaxial cable will experience an increase in insulation medium and conductor loss (Loss) when transmitting high-frequency signals; the higher the frequency, the more pronounced the heat generation.

Solution and Optimization Suggestions for Heating of Extremely Fine Coaxial Beam

1. Reasonable selection

According to the system's current, voltage, and signal frequency, select the appropriate wire gauge, shielding density, and temperature resistance grade to ensure that the wire material has sufficient margin.

Optimize welding and connection techniques

Ensure that the welds are full and firm, and the terminal connections are reliable, to avoid cold solder joints or weak soldering, and reduce contact resistance from the root.

Recommendation: Regularly inspect connection points to prevent local overheating caused by oxidation or loosening.

3. Reasonable wiring and thermal design

Avoid bundles of wires being close to power devices or heat sources to ensure good air circulation.

Heat sinks, thermal pads, or insulating thermal barriers may be added as necessary to improve the system's thermal management.

Reduce signal frequency or use segmented transmission

For high-frequency signals, try to shorten the transmission distance, or reduce medium loss by segmenting and transferring.

Add protection and insulation measures

In high-temperature or high-reliability scenarios, heat shrinkable tubes and high-temperature insulation sleeves can be added to the outer layer to further improve the heat resistance and stability of the wire harness.

Extremely thin coaxial cables, although compact in size, undertake critical signal transmission tasks. If not handled properly in selection, welding, wiring, or thermal management, they are prone to overheating and even failure. Therefore, engineers should conduct electrical and thermal environment assessments in advance during the product design and debugging stages, scientifically match wire specifications and materials, and optimize the connection structure and heat dissipation layout to ensure the long-term stable operation of the equipment.

I am Kunshan JieKang Fu Precision Electronic, focusing on the design and customization of high-speed signal cables and ultra-fine coaxial cables for a long time, committed to providing stable and reliable high-speed interconnection solutions. If you have any related needs or want to learn more, please contact: Manager Zhang.

18913228573 (WeChat number)...