In the field of high-speed signal transmission, abnormal EMI (Electromagnetic Interference) has always been a persistent challenge for engineers. Especially in the rapidly miniaturized products such as consumer electronics, medical devices, and intelligent terminals, ultra-fine coaxial cables (Micro Coaxial Cable) are widely adopted due to their excellent signal integrity and flexibility. However, when data rates reach 10Gbps and above, the EMI issue becomes more challenging. So, how to deal with EMI anomalies in ultra-fine coaxial cables under high-speed signal environments? Today, we will delve into this topic in detail.

What is a micro coaxial cable (Micro Coaxial Cable)?

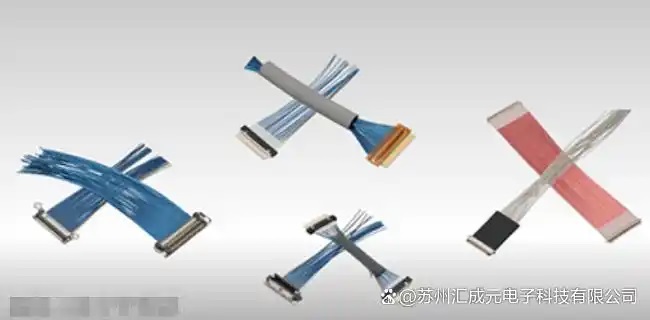

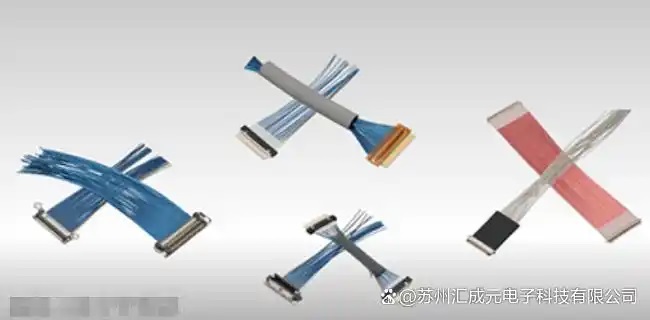

Extremely thin coaxial cable is a miniature coaxial cable with an outer diameter ranging from 0.3 to 1.2 mm, and its typical structure includes:

Inner conductor (central signal line)

Insulation layer

•屏蔽层(usually a woven layer + foil)

outer sheath

This wire material not only has excellent shielding performance like traditional coaxial structures, but also features small diameter, good flexibility, and ease of bending, thus widely used in space-limited devices such as smartphones, laptops, medical probes, and in-car imaging systems.

Why is it easier to have EMI anomalies under high-speed signals?

As the signal frequency increases, the signal rise time becomes steeper. High-speed digital signals are essentially the superposition of a large number of high-frequency harmonics, which can lead to the following problems:

屏蔽层泄漏

Common-mode interference increases

Grounding system stray coupling

• High wiring density leads to crosstalk

These factors work together, causing ultra-fine coaxial cables to exhibit the following EMI anomalies at speeds above 10Gbps:

Wireless performance test failed.

EMC radiation exceeds the standard

High-frequency signal interference with adjacent channels

How to investigate and resolve EMI anomalies?

1. Method for troubleshooting EMI anomalies

Use a spectrum analyzer + near-field probe to locate the interference source

S-parameters measured by network analyzer

Utilize signal integrity simulation to predict frequency sensitive sections

Switch to different models or lengths of Micro Coax cables for A/B comparison tests

Effective improvement plan

2.1 Optimize Cable Selection

Choose products with a shielding weaving density of ≥90% to enhance shielding integrity.

2.2 Adopt a double-screening structure

That is, "weaving layer + foil layer", and配合low dielectric constant insulating materials to reduce signal loss and reflection.

2.3 Wiring and grounding strategy

• Suggest single-point grounding for extremely fine coaxial cable束

Avoid parallel wiring with high-speed differential signal lines or antenna cables.

Maintain a reasonable spacing from the metal shell or the grounding copper skin.

2.4 Additional EMI Suppression Devices

Add common-mode magnetic rings at both ends of the harness.

Cover sensitive sections with **EMI Absorber Sheets**.

Where necessary, use shielding covers to enhance the shielding effect.

Optimize harness length and routing

Avoid excessively long, dense, or tangled wiring.

Adjust the harness space layout, reduce length differences, and prevent common-mode excitation.

In high-speed signal applications, the EMI problem of extremely thin coaxial cables is not uncontrollable. By selecting cables reasonably, designing wiring in accordance with standards, conducting precise testing and troubleshooting, and complementing with efficient EMI suppression devices, electromagnetic interference can be fully controlled within the product certification requirements, achieving stable and reliable high-speed signal transmission.

I am Kunshan JieKangFu Precision Electronics, focusing on the design and customization of high-speed signal cables and ultra-fine coaxial cables for a long time, committed to providing stable and reliable high-speed interconnection solutions to customers. If you have any related needs or want to learn more, please contact: Manager Zhang.

18913228573 (WeChat same number).