Categorization:Harness Component

The importance of flexible design

In the multi-axis linkage process, the wire harness not only needs to transmit high-speed signals but also withstand tens of thousands of bends and twists. If the flexibility is insufficient, it is prone to breakage, poor contact, and even affect the overall operation of the machine. The extremely thin coaxial harness with small diameter and compact structure can achieve large-angle bends within a limited space, effectively extending the service life and improving the overall reliability of the robot system.

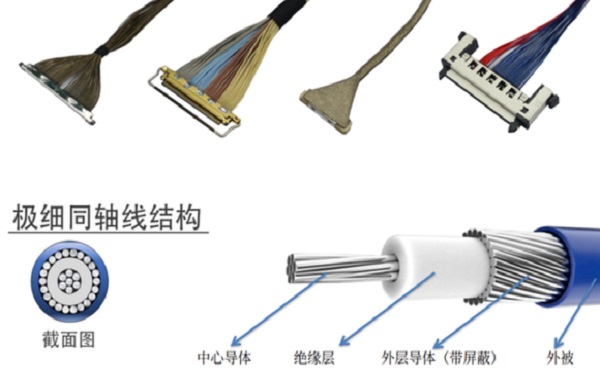

The advantages of extremely fine coaxial cable束

High flexibility: The design of micron-level conductors and fine shielding layers allows the cable束 to adapt to continuous swinging and twisting.High transmission performance: with good impedance control and low attenuation characteristics, meeting the needs of high-speed signal transmission.

Lightweighting: significantly reducing the diameter of the robot arm minimizes load, improving operational efficiency.

High reliability: maintains signal stability under complex multi-axis motion conditions, reducing the risk of failure.

High durability: Some high-end ultra-fine coaxial cable bundles can withstand more than 10 million bending cycles, extending the equipment maintenance cycle.

Application scenarios

Sensor and camera signal transmission in collaborative robots (Cobots)Real-time signal transmission in high-precision welding robots

High-speed data link in semiconductor equipment handling robots

Miniaturized image signals and control lines in medical surgical robots.

Four, future development trends

With the improvement of robot intelligence, wire harness design will focus more on the following directions:

Smaller diameter: meets the requirements of robotic end-effector joints and compact structural wiring.Higher bandwidth: supports high-definition video, AI sensors, and 5G communication modules.

Modular solution: Achieve quick replacement and efficient maintenance through customized harness components.

I amSuzhou Huichengyuan Electronic TechnologyLong-term focus on the design and customization of high-speed cable harnesses and extremely thin coaxial cables, committed to providing stable and reliable high-speed interconnect solutions. If you have related needs or want to learn more, please contact us:Manager Zhang 18913228573 (WeChat same number)。