With the continuous increase in requirements for high-speed signal transmission and lightweight design of electronic devices, micro coaxial cable, with its excellent anti-interference performance, high-speed transmission capabilities, and flexibility, has been widely used in high-precision equipment such as smartphones, tablets, in-car display systems, and camera modules. However, the connection quality of such cables directly affects the signal stability and service life of the entire machine, making the reliability of its open-short circuit detection particularly crucial. This article takes HRS DF56-30P-0.3SD as an example to analyze the standard detection process for micro coaxial cables.

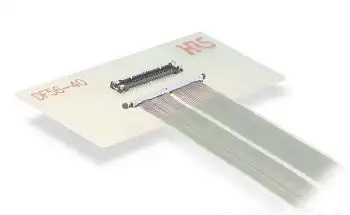

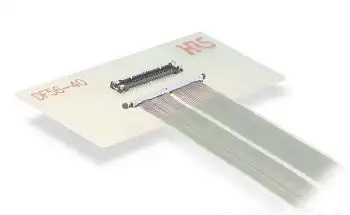

HRS DF56-30P-0.3SD connector introduction

HRS DF56-30P-0.3SD is a super mini, high-density PCB-to-line connector launched by Hirose Electric of Japan, designed specifically for high-speed signal transmission equipment. Its main features are as follows:

Ultra-fine pitch design: Pitch spacing only 0.3mm, compatible with high-density wiring requirements.

Supports extremely thin coaxial cables: perfectly compatible with micro coaxial cable, for high-speed signal transmission scenarios.

Stable lock buckle structure: Equipped with vibration resistance and anti-loosening functions to ensure stable connection.

Multi-channel signal capability: 30 terminal design, meets the parallel transmission of multiple signals.

Wide application fields: Often used in devices with high requirements for size and signal integrity, such as smartphones, tablets, in-car cameras, and security modules.

Second, the standard process for detecting short-circuits in extremely fine coaxial cable bundles

To ensure the product's quality upon shipment, the micro coaxial cable harness must undergo a systematic open-short circuit test after assembly. The following are the standard testing steps:

Connector terminal pre-inspection

Check the terminal status of HRS DF56-30P-0.3SD to ensure there are no issues such as loose connections, damage, or misalignment, and ensure the connector is intact and undamaged.

Open Test

Use a professional wire harness tester to check the conductivity between each core wire and terminal one by one, confirming there are no phenomena such as broken wires, poor soldering, or poor crimping.

Short Circuit Test

Check for short circuits between core wires, between core wires and ground wire as well as between shielding layer, to prevent signal interference or motherboard damage.

High Voltage / Insulation Test

According to the project requirements, conduct insulation withstand voltage tests on the harness from 300V to 500V to verify its resistance to high-frequency crosstalk and insulation performance.

• Appearance re-examination

Check the appearance of the connector terminals, latches, and solder joints to ensure they are good, free of any abnormalities such as contamination, deformation, or residual glue.

Fine coaxial cable bundle short-circuit and open-circuit detection is a critical link to ensure the stability and long-term reliability of electronic device signal transmission. Especially when using high-density precision connectors such as HRS DF56-30P-0.3SD, it is necessary to strictly comply with detection standards to ensure that each cable bundle can operate stably under high-speed, high-frequency working environments.

We have been focusing on the design and customization of high-speed cable harnesses and ultra-fine coaxial cables for a long time, committed to providing stable and reliable high-speed interconnection solutions. If you have any related needs or would like to learn more, please contact: Manager

18913228573 (WeChat number).