Categorization:Harness Component

Signal integrity: the fundamental for ensuring无损 transmission of images

High-resolution, high-frame-rate visual data such as 1080P@120fps, 4K/8K videos require extremely high link signal integrity. The extremely fine coaxial cable bundle, with its coaxial shielding structure and strict impedance control, can effectively suppress crosstalk and reflection, reduce error rates, and maintain signal waveform stability. For Intel industrial cameras that emphasize real-time performance and accuracy, this cable bundle not only ensures the complete transmission of high-speed data but also ensures that every frame of the image is transmitted accurately, avoiding issues such as image jitter, frame dropping, and screen flickering.

Interference Resistance: Stable Guarantee in Industrial Environments

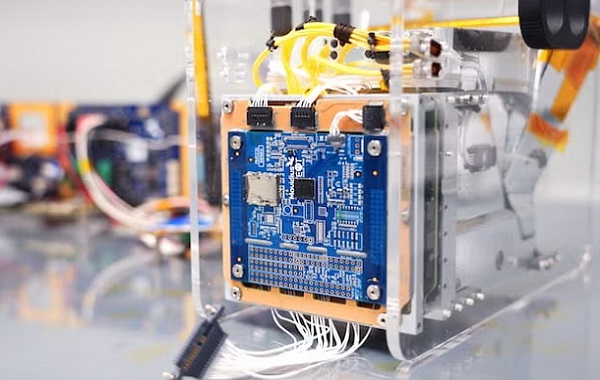

There are a large number of interference sources in industrial environments, such as high-speed motors, inverters, and welding equipment, which make ordinary wiring very susceptible to EMI interference. The extremely thin coaxial cable bundle has an excellent shielding layer design, which can maintain signal purity even in strong electromagnetic environments, significantly reducing interference points and improving image transmission stability. This anti-interference capability makes it possible for Intel industrial cameras to operate stably in complex scenarios such as automated production lines and robot systems for a long time.

Three, wiring flexibility: the ideal solution in narrow spaces

Industrial vision equipment is usually installed in compact locations, such as the end of robotic arms and small equipment cavities. Traditional thick wires are difficult to bend and occupy a large space, which often leads to issues like breaking or loosening. The extremely thin coaxial cable has a small outer diameter and high flexibility, allowing for free wiring in compact structures, narrow passages, and movable joints, improving installation efficiency and providing more layout space for equipment design. This makes it a combination of performance and engineering practicality in industrial camera systems.