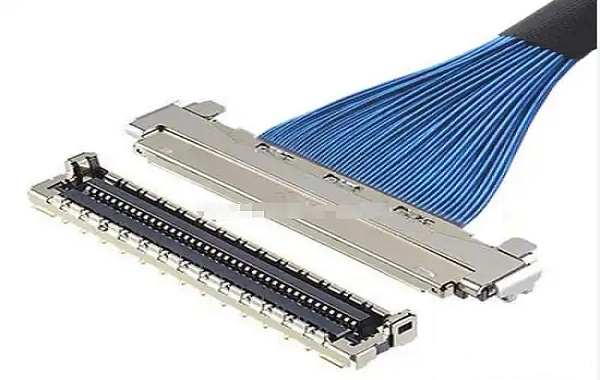

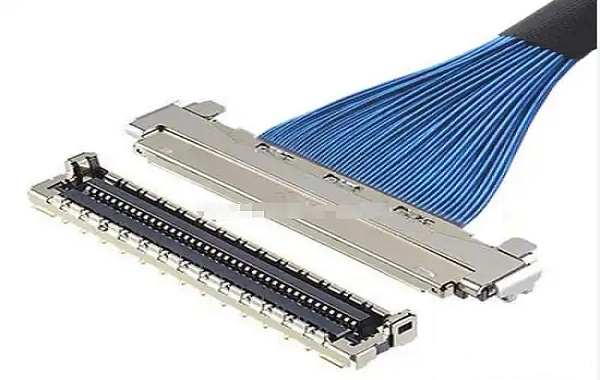

In systems with high-speed signals, high-density wiring, and complex electromagnetic environments, the shielding structure of cables often directly determines signal integrity and the overall EMC performance. For multi-core composite coaxial cable bundles composed of multiple micro coaxial cables, when the transmission rate increases or surrounding interference intensifies, single-layer shielding is no longer sufficient to meet the EMI/EMC requirements, and multi-layer shielding structure becomes the key means to ensure reliability.

This article will systematically explain the timing of using multi-layer shielding from three dimensions: necessity, typical application scenarios, and design points, to help engineers judge when "it can be adopted" and when "it must be adopted."

Why is multi-layer shielding necessary?

The emergence of multi-layer shielding is not for stacking materials, but to solve the inherent electromagnetic problems of multi-core coaxial cables in high-density environments.

The shielding capability of a single coaxial cable is not sufficient to cover the entire cable bundle.

Although the micro coax itself has a woven layer or foil layer for shielding, when dozens to hundreds of coaxial cables are arranged in parallel to form a cable assembly, the overall crosstalk, coupling, and EMI leakage are significantly increased, exceeding the range that can be effectively suppressed by a single layer of shielding.

Internal crosstalk and external interference coexist

The spacing between high-speed signals is limited, which is prone to crosstalk; at the same time, electromagnetic noise from motors, RF sources, power components, etc., may intrude into the harness and disrupt signal stability.

3. Multi-layer shielding provides graded protection

Inner shielding: Used to suppress the basic interference of each coaxial cable

● Improve the isolation between wires inside the harness, reduce crosstalk

Outer shielding: effectively resist radiation and interference from the surrounding environment

Through multi-level and wideband shielding structures, the overall anti-interference performance of the harness can be significantly improved, which is an extremely important technical means in high-speed and high-end interconnect harnesses.

Which applications must use multi-layer shielding?

Although multi-layer shielding may bring certain costs and technological complexity, the following scenarios are usually mandatory requirements:

High-speed or high-frequency signal chain

Typical examples include high-speed cameras, radar, digital vision systems, 5G radio frequency links, and ultrasonic imaging, etc. High-speed signals are extremely sensitive to interference, and multi-layer shielding can effectively maintain the eye diagram and bit error rate indicators.

Low signal acquisition and high-precision medical equipment

Medical ultrasonic probes, precision testing devices, weak charge collection systems, and so on. Such signals have extremely low amplitudes, and even a small amount of noise can cause measurement distortion, so double or triple shielding is usually required.

3. Industrial, vehicle-mounted, and other strong interference scenarios

Inverter, robotic arm, robot, vehicle-mounted radar and camera, and the electromagnetic environment noise around them is strong. To meet the EMC standards, multi-layer shielding is often a standard configuration.

4. Systems with dense wiring or longer cable lengths

Long-distance transmission can cause interference accumulation, dense cabling can worsen the distribution parameters between signals, and multi-layer shielding can effectively reduce noise coupling.

5. Products requiring strict EMC/EMI certification

Aviation, automotive, and medical industries are extremely stringent in terms of interference tolerance, and multi-layer shielding is usually an important guarantee for certification.

How to design in order to truly achieve the multi-layer shielding effect?

To make multi-layer shielding truly effective, the following key points cannot be ignored:

Material pairing screening

Common combinations are metal foil layer + woven layer.

Foil layer has better shielding ability for high-frequency EMI

● The woven layer is more suitable for low-frequency interference and improves structural flexibility

Both can synergistically achieve a wideband shielding effect.

The grounding method must be reasonable.

Improper grounding can cause ground loops, which反而 introduce noise.

Outer屏蔽 usually adopts both ends grounded to improve the overall shielding efficiency.

● The inner shielding can be selected to use single-ended or double-ended grounding strategy according to the nature of the signal

3. Consider flexibility and mechanical life

The multi-layer shielding will increase the overall rigidity of the cable harness, especially in dynamic scenarios such as camera movement lines and robot arms, where it is necessary to ensure that the sheath has sufficient bending life.

4. Focus on manufacturing process and cost

The multi-layer shielding structure is complex and requires verification of EMI margin, manufacturability, and reliability during the trial production phase to avoid cost waste caused by excessive or insufficient performance.

Multi-layer shielding is not required for all harness projects, but in systems with high speed, weak signals, strong interference, or complex wiring, it often determines the upper limit of the signal chain. From signal integrity to EMC certification, from anti-interference stability to mass production reliability, multi-layer shielding is a key investment for engineers to ensure robust system operation. Through reasonable material selection, grounding strategy, and structural design, the anti-interference ability of the harness can be greatly improved, providing more sufficient safety margin for the product.

I am

[Suzhou Huichengyuan Electronic Technology]Long-term focus on the design and customization of high-speed signal cable harnesses and ultra-fine coaxial cable harnesses. For more information or customization development, please contact Manager Zhang:

18913228573(WeChat number same)。