As smartphones, wearable devices, foldable screens, and thin notebooks continue to develop towards miniaturization and high-speed transmission, the flexibility and reliability of internal wires have become key design factors. Among them, ultra-fine coaxial cables, due to their advantages such as high density, high shielding, and good flexibility, have become the mainstream solution for high-speed signal interconnection. However, in actual structures where bending is frequent, does it affect the signal quality?

This article will analyze the relationship between the bending times of ultra-thin coaxial cables and signal integrity in detail, combining the I-PEX CABLINE®-UX II series 20532-040T-02-1 connector, and provide practical selection suggestions.

I-PEX 20532-040T-02-1 Product Introduction

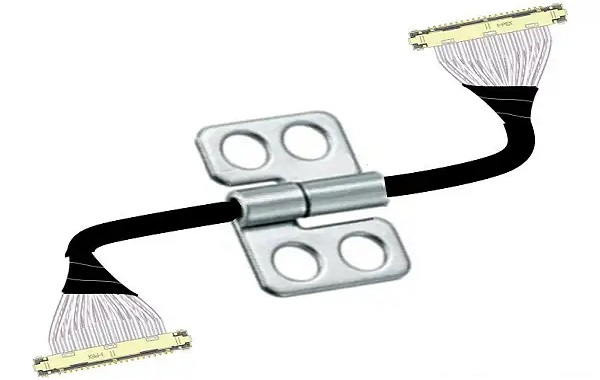

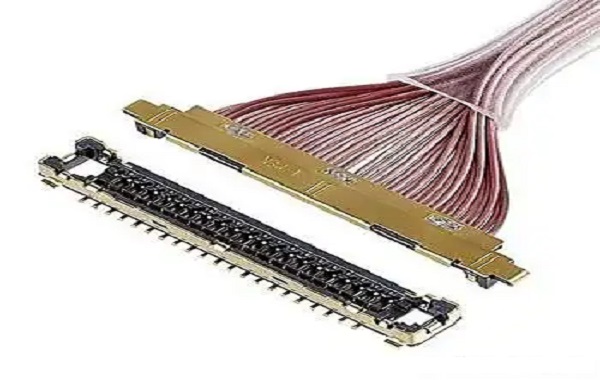

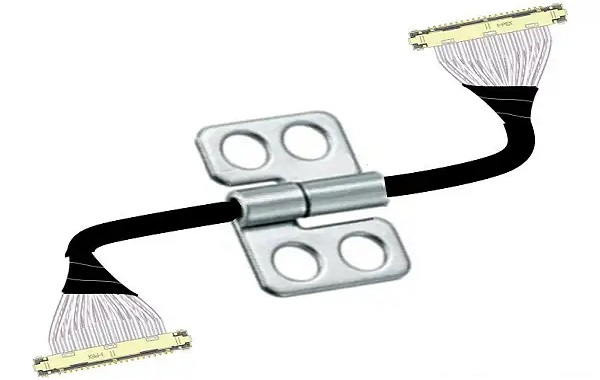

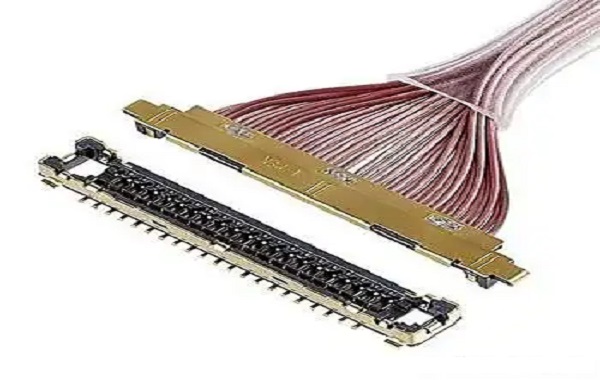

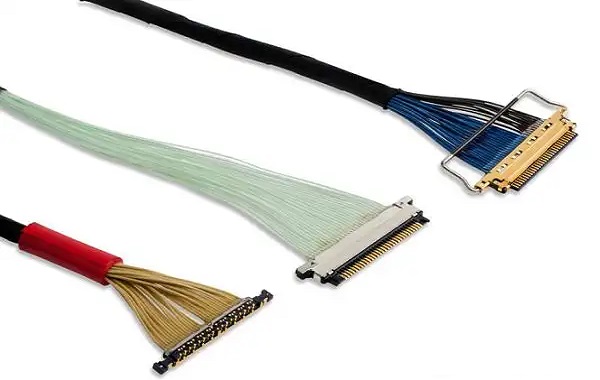

The I-PEX CABLINE®-UX II series includes the 20532-040T-02-1 plug shell, specifically designed for ultra-thin coaxial (micro coax) interconnections, suitable for vertical bending structure design. Its contact spacing is only 0.25mm, supporting AWG #44–#46 wire diameters, with an overall height of approximately 1.1mm, making the structure extremely compact.

The connector adopts the multi-point grounding ZenShield® technology, with good EMC performance and environmental protection certifications such as RoHS, REACH, and PFAS. Its ultra-thin and flexible design makes it suitable for space-limited and dynamic bending applications, such as foldable smartphone hinges, notebook hinges, VR/AR devices, and so on.

The effect of the number of bends on ultra-fine coaxial cables on signal quality

Physical fatigue leads to impedance shift

Fine coaxial conductor and insulating layer may develop micro-cracks after multiple bending, causing impedance deviation, which in turn leads to signal reflection or attenuation, and is a common隐患 in high-speed transmission design.

Structure may be damaged

Bending stress can affect the integrity of the coaxial shielding layer. If the shielding layer becomes loose or damaged, it will reduce the anti-EMI capability and cause the signal quality to deteriorate.

Problem of stress concentration in the junction area

At the plug end, especially for connectors with mechanical locking tabs or metallic shielding structures, bending may concentrate stress in the area near the terminals, possibly causing unstable contact or the plug to become loose.

The multi-point grounding structure of the UX II series can improve the resistance to mechanical stress to a certain extent, but still needs to be matched with reasonable wiring and protection.

Section 3: Application Recommendations and Wire Selection Reference

Pay attention to the bend life of the wire material

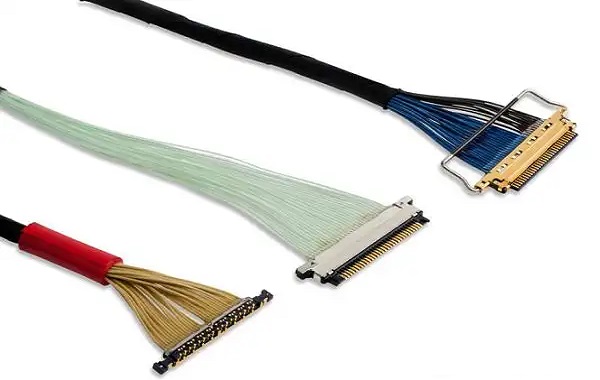

In applications that require multiple dynamic bending, such as hinge, foldable screen, VR sensor ribbon cables, it should be prioritized to choose micro coaxial cable materials that have explicit bend test reports and are specifically designed for dynamic applications.

Choose the appropriate wire diameter and structure.

AWG #46 and finer wire diameters offer better flexibility and wiring capabilities, suitable for ultra-small space designs; paired with I-PEX's locking and shielding structure, it can further improve connection stability.

3. Consider high-speed transmission and shielding requirements

Ensure the use of connectors with multi-point grounding and good shielding structures for high-speed interfaces such as USB4, MIPI, and PCIe. The CABLINE®-UX II series has significant advantages in EMI suppression and signal integrity.

Confirm environmental protection regulations requirements

20532-040T-02-1 meets RoHS, REACH, PFAS and other standards, which helps to improve the material safety of the whole machine for long-term use and meets the quality requirements of various brand customers.

Extremely thin coaxial cables play a key role in high-speed, miniaturized equipment. The number of bends they can withstand indeed significantly affects signal quality, including issues such as conductor fatigue, shielding layer damage, and impedance shift. By selecting appropriate cable specifications, reliable connector designs (such as the I-PEX CABLINE®-UX II series), and combining with sufficient bend life testing, it is possible to effectively balance structural flexibility and signal integrity, providing terminal equipment with long-term stable high-speed interconnection capabilities.

I am

[Suzhou Huichengyuan Electronic Technology]Long-term focus on the design and customization of high-speed cable harnesses and extremely thin coaxial cables, committed to providing stable and reliable high-speed interconnect solutions. If you have any related needs or want to learn more, please contact Manager Zhang.

18913228573 (WeChat number)。