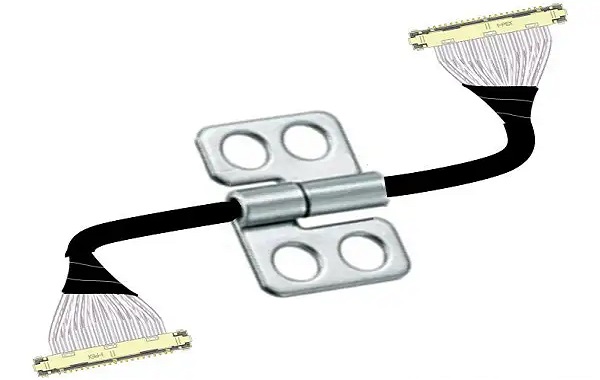

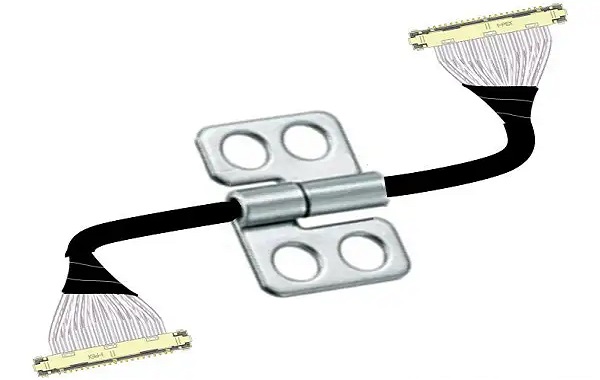

As mobile devices, ultra-thin laptops, and image modules develop towards higher speed and miniaturization, micro coaxial cable has become the mainstream transmission medium for high-speed interfaces such as MIPI, LVDS, and eDP. Among them, the I-PEX CABLINE®-UX II series (such as 20532-050T-02) is widely used in camera modules, hinge cables, and robotic equipment due to its 0.25 mm spacing, thin, light, and flexible structure.

This article will take the cable配套 with the connector as an example, focusing on the key influence of the intermediate dielectric material on signal integrity, loss performance, and reliability.

I-PEX 20532-050T-02: A typical representative in high-speed interconnection

I-PEX CABLINE®-UX II series adopts a shallow, ultra-thin structure and vertical insertion method, with the 20532-050T-02 supporting up to a 50-pin configuration, suitable for high-speed differential signal transmission. This series has passed environmental certifications such as PFAS-free, halogen-free, and RoHS / REACH, meeting global customers' strict requirements for environmentally friendly materials. Its wide application in MIPI camera, laptop hinge cable harnesses, and smart devices also reflects its advantages in miniaturization, flexibility, and high-frequency performance.

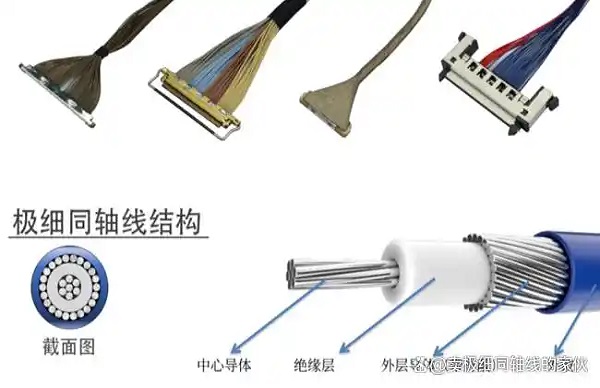

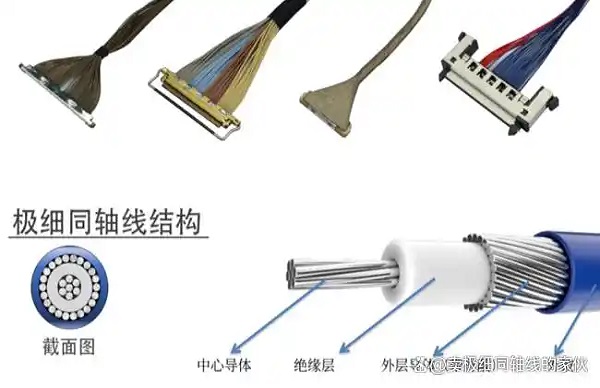

Second, the structure and importance of the dielectric layer in micro coaxial cable

The extremely thin coaxial cable is mainly composed of the central conductor, dielectric layer, metal shielding, and outer sheath, among which the dielectric layer is the core link that determines the characteristic impedance and signal attenuation.

• Characteristic Impedance Control: Dielectric constant (Dk) directly affects impedance, deviation can cause reflection and code distortion, and high-speed protocols (MIPI, eDP, USB, PCIe) are particularly sensitive.

• Loss and Eye Diagram Performance: The lower the medium loss, the better the insertion loss and return loss, which is conducive to maintaining the eye diagram opening and overall signal quality.

• Mechanical flexibility: Extremely thin coaxial cables are commonly used in hinge wiring scenarios. The dielectric material needs to balance softness and creep resistance to ensure impedance stability under repeated bending.

• Environmental protection and compliance: With the strengthening of PFAS bans and halogen-free requirements, stable and environmentally friendly dielectric materials have become the standard configuration of high-end cables.

III. Dielectric Layer Selection and Application Recommendations Based on I-PEX 20532-050T-02

To ensure the best transmission performance under high-speed protocols such as MIPI CSI-2, eDP, and others, optimization of the dielectric layer selection can be approached from the following aspects:

Impedance matching priority: Select materials with a dielectric constant of approximately 2.2–2.5 to achieve cable impedance control of 50 Ω ±5%.

2. Flexibility and bending properties: Ensure that dielectric materials maintain physical stability and do not undergo creep under ultra-small bending radii (such as 6× wire diameter).

3. Batch consistency: High-quality materials improve the consistency of impedance and loss in the same batch of cables, reducing the pressure on system debugging.

Environmental Material Selection: PFAS-free, halogen-free solutions consistent with certification material 20532-050T-02 better align with industry trends and customer requirements.

The dielectric layer is the core of the performance of the micro coaxial cable, having a direct impact on impedance, loss, flexibility, and environmental adaptability. The CABLINE®-UX II series, represented by I-PEX 20532-050T-02, can provide high consistency and reliability in high-speed transmission environments such as MIPI, eDP, LVDS, through a stable material system and precise manufacturing process. Choosing the appropriate dielectric layer material will significantly enhance the overall performance and lifespan of the high-speed cables in actual application.

I am

[Suzhou Huichengyuan Electronic Technology],Long-term focus on high-speed signal cable harness and ultra-fine coaxial customization, committed to providing customers with stable and reliable high-speed interconnection solutions. For inquiries or customization needs, please contact Manager Zhang:

18913228573 (WeChat number)。