Categorization:Harness Component

Electrical Performance and Signal Integrity

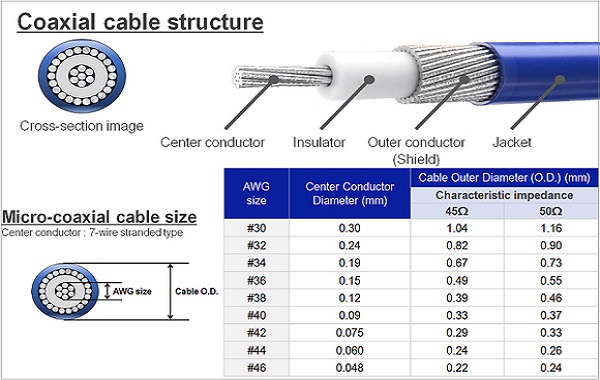

The extremely thin coaxial cables are mainly used for high-speed signal transmission, with signal integrity being the primary consideration. Precise control of the outer diameter ensures low loss, low crosstalk, and stable impedance matching. If the cable is too thick, it will be difficult to match the miniaturized interface design; if too thin, the shielding layer will be insufficient, leading to signal attenuation and interference. The outer diameter range of 0.3~0.5mm, while ensuring the quality of high-speed transmission, also takes into account the interface compatibility and design flexibility.

Flexibility and Spatial Adaptability

In scenarios with limited internal space in smart phones, tablets, industrial cameras, and AR/VR devices, flexibility and volume optimization of wiring are particularly important. The extremely thin coaxial cables with a diameter of 0.3~0.5mm can maintain sufficient flexibility, support orderly wiring of multiple cables in narrow spaces, and also ensure mechanical strength to avoid damage caused by pulling or bending of excessively thin wires, meeting the dual requirements of precision equipment for volume and reliability.

Process reliability and durability

The production of extremely fine coaxial cables involves micro-sized conductor and shielding technologies. The outer diameter range of 0.3~0.5mm is a mature process window, which ensures the stability of mass production while also considering tensile strength, bending life, and welding reliability. At the same time, this size ratio is conducive to heat dissipation and durability, making the cable stable under high-speed data transmission and long-term working conditions, and less prone to premature failure due to mechanical fatigue or heat accumulation.