Categorization:Harness Component

Why must the MIPI channel be consistent?

The MIPI interface consists of multiple data channels and clock channels, which work simultaneously at rates up to several hundred MHz to several GHz. If the transmission delay of each channel is different, it may cause inconsistent arrival time of data, leading to image frame errors or display anomalies. At the same time, impedance inconsistency can cause signal reflection, crosstalk, and error codes, therefore ensuring consistency across multiple channels is the foundation of high-speed signal integrity.

The natural advantages of ultra-fine coaxial lines

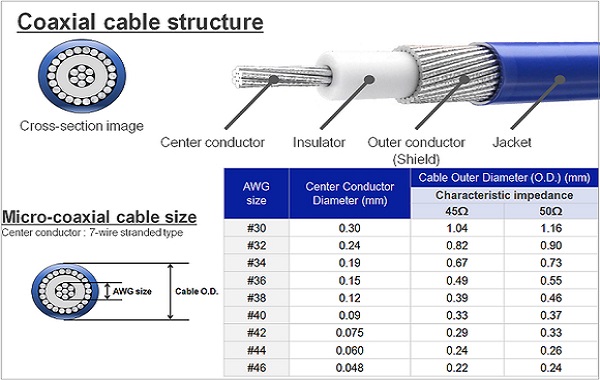

Extremely fine coaxial cables use a miniature structure consisting of a central conductor, insulation layer, shielding layer, and outer sheath, with each line being an independent shielding unit. Compared to traditional FPC or ribbon cables, Micro Coax offers a smaller diameter and higher flexibility while also providing high-frequency performance, precise impedance, and channel consistency. During the production process, the thickness of the dielectric and the size of the conductor can be strictly controlled to achieve a characteristic impedance of 50 Ω or 100 Ω, while ensuring that the delay of each channel is basically consistent. These advantages make it widely used in mobile phone cameras, industrial cameras, and vehicle imaging systems.

Three, key control points for achieving channel consistency

To achieve synchronization and impedance matching in a multi-channel MIPI system, strict control must be maintained throughout the design and manufacturing process. Firstly, the length of each line must be strictly consistent, using fixed-length trimming and equal-length winding to ensure signal synchronization; secondly, precise control of impedance and termination structure must be maintained to avoid sudden impedance changes; the shielding layer and grounding method must be unified to reduce interference between channels; at the same time, ensure consistency in conductor, insulating material, and shielding process to avoid material differences leading to signal attenuation or phase shift. Finally, ensure that the cable meets the transmission requirements of high-speed MIPI through TDR testing, channel delay measurement, and high-speed signal function verification.