Categorization:Harness Component

Why must differential pairs be of equal length?

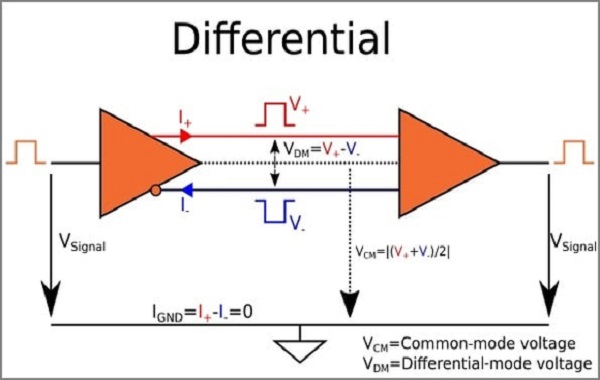

Differential signals consist of paired positive and negative lines, and the receiving end relies on the differential voltage between the two lines to determine the signal. Therefore, if there is a length difference between the two lines, it will cause inconsistent propagation delays, forming Skew, which makes the eye diagram worse, increases crosstalk, and may even cause high-speed links to fail to operate normally. In addition, differential impedance usually requires maintaining around 100 Ω, if the path is not consistent, it may cause impedance jump and reflection, thereby affecting signal integrity. In multi-channel high-speed systems, the consistency of arrival time between multiple pairs of differentials is also very important, therefore, equal length of differential pairs is a basic requirement for high-speed signal design.

Why choose ultra-fine coaxial cable for differential transmission?

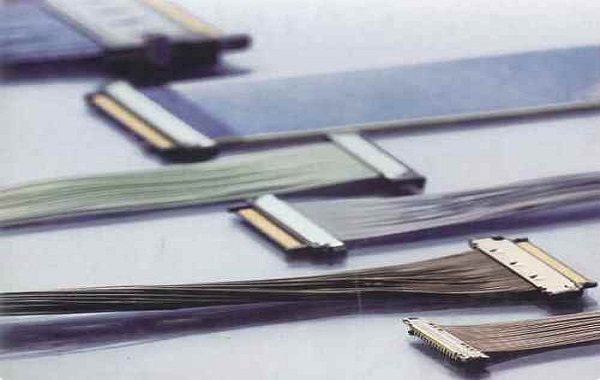

Extremely thin coaxial cables have a complete structure consisting of a central conductor, insulating layer, shielding layer, and outer sheath, which naturally endows them with independent shielding, low loss, and low crosstalk advantages. They can not only meet high-speed transmission of more than 10 Gbps but also have the characteristics of small diameter and high flexibility, making them very suitable for small space devices such as camera modules, laptops, and industrial cameras. In high-speed differential applications, the uniform structure and excellent electrical performance of Micro Coax cables can significantly improve signal integrity; however, due to the lack of fixed coupling between cables, precise control of length and path consistency is required during processing.

How to make extremely thin coaxial cables achieve equal-length differential?

To ensure that two coaxial axes maintain a consistent electrical path, strict control must be exerted during the design and manufacturing stages. Firstly, the cutting of the wires needs to ensure consistent physical length, and necessary adjustments should be made to compensate for length differences; secondly, the entire bundle of wires needs to maintain consistent material to avoid variations in the medium that could lead to changes in propagation speed; during processing, the two wires need to be arranged symmetrically to ensure consistent bending and force; after completion, the propagation delay of the two lines must be confirmed consistent through TDR and other testing equipment to ensure the true meaning of "electrical equal length."