Categorization:Harness Component

The skin effect determines the importance of materials.

In high-speed and high-frequency transmission environments, the current is mainly concentrated in the surface flow of the conductor, known as the "skin effect." The higher the frequency, the closer the current tends to the outer layer, and the internal part of the conductor almost no longer participates in conduction. Therefore, the loss and integrity of high-speed signals are almost entirely determined by the material of the conductor's surface. Silver, as the metal with the highest electrical conductivity, its low resistance characteristics can significantly reduce high-frequency loss, keeping the signal clearer during transmission. Therefore, silver plating on the cable surface has become the core method to improve high-speed performance.

Why choose silver-plated copper instead of pure silver?

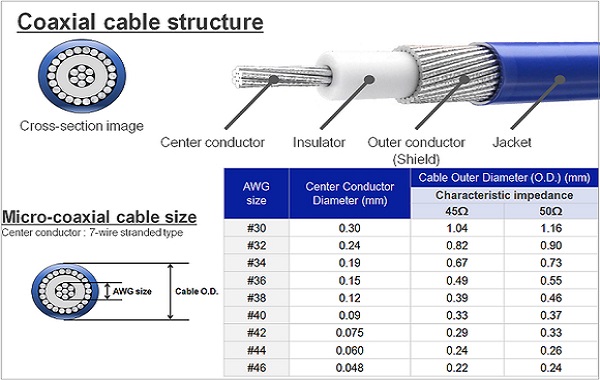

Although silver has the best conductivity, pure silver materials are too soft, expensive, and lack mechanical strength, making them unsuitable as the core of fine conductors. Copper cores provide excellent mechanical strength and stability, while silver plating on the surface ensures high-speed, low-loss signal transmission along the surface. This structural combination combines the advantages of both: the silver layer takes on the high-frequency conductivity task, the copper core provides structural support, and silver plating also improves antioxidant ability and long-term reliability. For extremely thin coaxial cables with a wire diameter of only about 0.1mm, this "copper-based and silver-plated" design is particularly crucial.

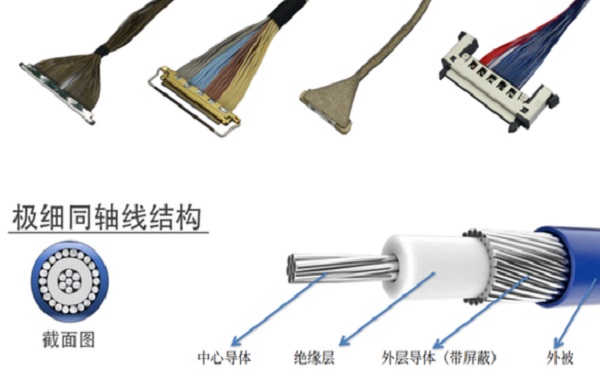

III. Performance Improvement and Practical Application Value in Ultra-Fine Coaxial Cables

High-speed interfaces such as USB4, PCIe, MIPI, LVDS, etc., have extremely high requirements for loss, reflection, and impedance consistency. Silver-plated copper conductors can significantly improve insertion loss, enhance antioxidant properties, strengthen solderability reliability, and ensure high consistency of impedance structure, reducing eye diagram distortion and communication errors. This makes them the standard configuration in fields such as high-speed image equipment, AI server backplane connections, autonomous driving sensors, and 5G modules, serving as an important foundation for ensuring stable output.