Categorization:Harness Component

Part 1: Common High-Speed Interfaces and Their Applications

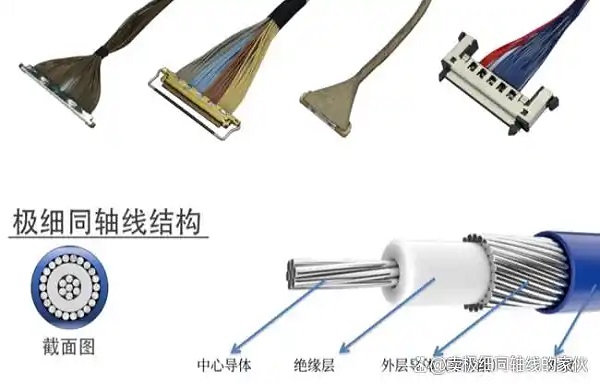

Mainstream high-speed interfaces include PCIe, USB 3.x/4.0, HDMI, DisplayPort, MIPI, SAS/SATA, OcuLink, SlimSAS, and Thunderbolt, among others. These interfaces are widely used in scenarios such as CPU, GPU, high-speed storage, displays, camera modules, and high-end notebook expansion docks, where there is a very high requirement for signal integrity and transmission stability. To meet the needs of high-speed and high-frequency design, extremely thin coaxial cables (micro coaxial cable) are often used for internal connections within the interfaces, ensuring high bandwidth and low interference transmission performance.

The core reason for the instability of high-speed signals

High-speed interface signal instability is mainly caused by various factors. Firstly, improper transmission medium selection, such as inaccurate cable impedance or insufficient shielding, can lead to signal jitter and error codes. Secondly, high-speed transmission is prone to crosstalk and reflections, and unreasonable differential line spacing control and shielding design can cause eye diagram closure. Moreover, defects in connector design and welding technology, such as excessive contact resistance or cold solder joints with voids, can also disrupt signal continuity. Lastly, environmental factors such as temperature changes, repeated bending, and long-term fatigue have a significant impact, especially on extremely thin coaxial cables with very small diameters.

Three, methods to improve the stability of high-speed interface signals

To improve signal stability, it is necessary to approach from multiple aspects such as design, material selection, and process. Optimize the cable harness design, choose ultra-fine coaxial cables with precise impedance control and low loss; strengthen the shielding structure to enhance anti-interference ability and reduce crosstalk issues; use high-quality connectors and assembly processes to ensure reliable terminal contact and avoid process defects; according to the application environment, add characteristics such as bend resistance and high temperature resistance to improve the long-term reliability of the cable harness. Only by fully controlling the design, materials, processes, and verification stages can the stable and reliable transmission of high-speed interfaces be achieved.