In the fields of industrial automation, electrical control, and distribution systems, American Electrical, as a well-known connector brand in North America, is widely recognized for its reliable mechanical structure, electrical performance, and durability. Its products such as DIN track terminals, jumper systems, and grounding modules have a high market share in the European and American markets and are commonly used in industrial control cabinets, PLC systems, rail transit, and energy management equipment.

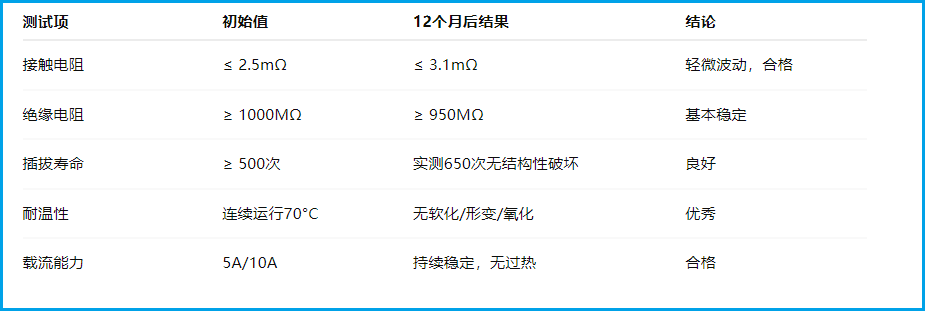

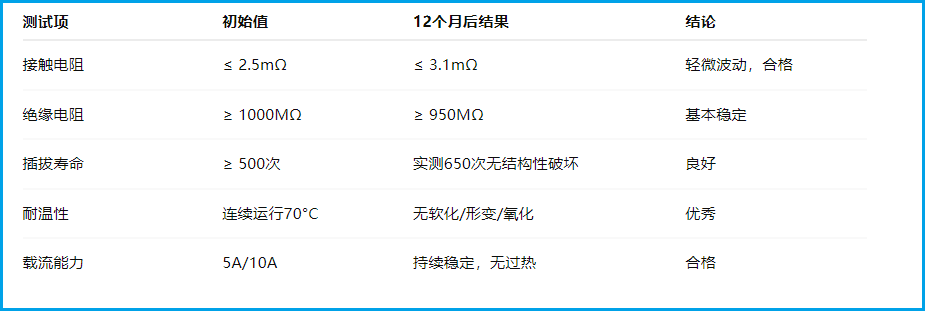

But in recent years, with the enhancement of the domestication trend of the supply chain, many terminal customers have started to pay attention to the performance of domestic connectors, especially whether they have the potential to replace in terms of long-term stability. For this purpose, we conducted a comprehensive test on a batch of domestic connector products that are benchmarked against American Electrical for a period of 12 months, and the test results are as follows.

✅

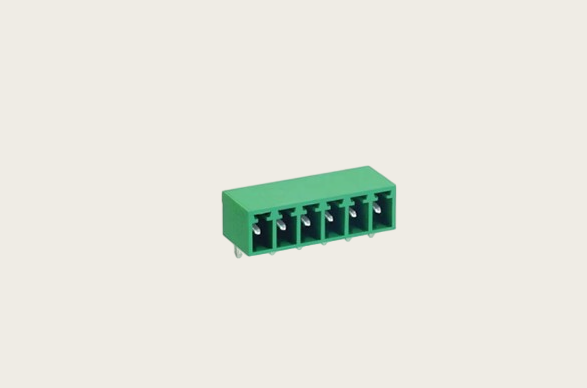

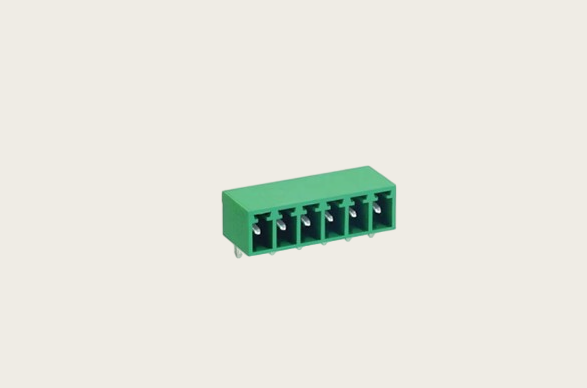

Test descriptionTested Product: Domestic DIN rail connector for American Electrical standard

Test cycle: 12 months

Application scenario: Industrial control cabinets (high temperature/high humidity/high-frequency plugging and unplugging environment)

Test indicators:

● Contact resistance change rate

Insulation resistance stability

● After insertion and extraction, mechanical integrity

● Continuous operation performance at high temperature (70°C)

● Voltage breakdown and current carrying capacity

✅

Sample performance analysis

✅

Comparative Analysis of American Electrical ProductsThe domestically produced connectors have been verified in actual use, and their electrical performance in conventional and light industrial strength application environments is not significantly different from the original American Electrical products. Especially in terms of insertion-extraction life, structural heat resistance, and contact stability, they have reached and even exceeded some imported standards.

In addition, in terms of cost control and supply response, domestic connectors have a significant advantage:

Cost reduction of 30%–50%

● Delivery period shortened from 4 weeks to 7 days

●Support for non-standard customization and quick prototyping

✅

Technical Progress Behind the Enhanced StabilityIn recent years, domestic connector manufacturers have made breakthroughs in the following directions:

Mold precision optimization: improve product consistency and assembly fit

Material Upgrade: UL94-V0 flame-retardant PA66 and high-purity copper conductor

●Process automation: Reduce manual assembly errors, improve batch stability

Surface Treatment Improvement: Tin Plating and Nickel Plating Process Enhanced Antioxidation Ability

These technical upgrades significantly reduce the performance attenuation of domestic connectors under long-term application environments, providing stable and safe alternative solutions for industry users.

The test results show that domestic connectors are fully capable of long-term stable replacement of American Electrical brand products. In today's pursuit of high cost-performance and rapid response, domestic solutions undoubtedly provide a more flexible and efficient choice for engineering projects, equipment integrators, and industrial end customers.

If you are interested in the domestic substitute products for this brand connector or have procurement needs, or if you have production or sales channels for the domestic substitute products of this brand connector and wish to engage in in-depth cooperation or communication, please contact via the following contact information:

Manager Zhang (18665383950, WeChat number the same)Contact us, we look forward to working together with more industry partners to create a new chapter of cooperation!